OM-MP80 E V1.15

January 29, 2015

Page 7

MP80

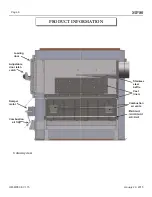

THIS UNIT MAY BE INSTALLED AS FOLLOWS:

1.

AS AN INDEPENDENT FORCED AIR FURNACE EQUIPPED WITH A HAC 900 CFM FAN AS

SHOWN IN DIAGRAM “A” BELOW.

2.

AS A DOWN STREAM SERIES DUCT ADD-ON TO ANY OF THE FOLLOWING FURNACES:

A.

OIL FURNACE HAVING OIL INPUT, AS SHOWN ON ORIGINAL NAMEPLATE, BETWEEN

.81 USGPH & 1.2 USGPH (MAX.). DIAGRAM “B”.

B.

A GAS FIRED FORCED AIR FURNACE HAVING A GAS INPUT, AS SHOWN ON ORIGINAL

NAMEPLATE, BETWEEN 60,000 MINIMUM AND 120,000 MAXIMUM BTU (17-35 kW) AND A

39-56°C(70-100°F) AIR TEMPERATURE RISE. MINIMUM FAN SIZE OF 900 CFM.

DIAGRAM

“B”.

C.

ELECTRIC FORCED AIR FURNACE RATED AT 10 KW TO 25 KW INPUT. MINIMUM FAN

SIZE 900 CFM. DIAGRAM “B”.

CHIMNEY REQUIREMENTS:

ALL FUEL CHIMNEY WITH MINIMUM SIZE OF 29 sq. in. (1820 sq. mm.). DO NOT CONNECT THIS

FURNACE TO A CHIMNEY SERVING A GAS APPLIANCE.

MINIMUM CLEARANCE:

WOOD CHARGING END

48 in.

(1200 mm)

ONE

SIDE

6

in.

(150

mm)

OTHER SIDE (FOR SERVICING)

18 in.

(460 mm)

FLUE

(COMBUSTIBLES, ELECTRICAL WIRE

AND ELECTRIC FURNACE)

18 in.

(460 mm)

PLENUM & FIRST 6 ft. OF DUCT

2 in.

(50 mm)

MINIMUM INTERCONNECT DUCT SIZE FOR ADD ON USE 12 in. (300 mm) x 18 in. (460 mm).

NOTE - NOT APPROVED FOR PARALLEL OR SPLIT PLENUM (ADD-ON SERIES ONLY APPROVED)

IF INSTALLED ON COMBUSTIBLE FLOOR THE FLOOR MUST BE PROTECTED 18 in. (460 mm) IN

FRONT OF WOOD CHARGING END. REFER TO INSTALLATION INSTRUCTIONS

INSTALLED BY

ADDRESS

DATE

OPERATING INSTRUCTIONS:

REFER TO DETAILED MANUFACTURER’S INSTRUCTIONS

1.

BURN WOOD ONLY

2.

LOAD FUEL CAREFULLY OR DAMAGE MAY RESULT

3.

FILL TO BOTTOM OF DOOR ONLY.

4.

DO NOT ATTEMPT TO LIGHT A FIRE WHEN THERE IS OIL OR GAS VAPOUR PRESENT.

5.

DO NOT USE CHEMICALS OR FLUIDS TO START FIRE.

CAUTIONS:

1.

DO NOT CONNECT DUCTWORK SO THAT A REVERSE FLOW IS POSSIBLE.

2.

OPERATE OIL /GAS / ELECTRIC FURNACE UNIT PERIODICALLY TO ENSURE THAT IT WILL

OPERATE SATISFACTORILY WHEN NEEDED.

3.

DO NOT RELOCATE OR BYPASS ANY OF THE SAFETY CONTROLS OF THE ORIGINAL

FURNACE INSTALLATION.

4.

DISCONNECT ELECTRIC POWER FROM BOTH ADD-ON FURNACE AND ELECTRIC/GAS/OIL

UNIT BEFORE SERVICING

5.

DO NOT BURN GARBAGE, NAPTHA, GASOLINE OR ENGINE OIL UNDER ANY

CIRCUMSTANCES.

6.

KEEP THE FIRE DOOR TIGHTLY CLOSED.

7.

IN THE EVENT OF A RUNAWAY FIRE OR CHIMNEY FIRE, CLOSE ALL COMBUSTION AIR, THE

DAMPER CHAIN CAN BE UNHOOKED FROM THE CAM TO MANUALLY CLOSE THE DRAFT.

CALL THE FIRE DEPARTMENT AND BE PREPARED TO EVACUATE THE HOUSE. CORRECT

THE PROBLEM BEFORE REFIRING.

8.

CLEAN HEAT EXCHANGER, FLUE PIPE AND CHIMNEY REGULARLY TO PREVENT A BUILDUP

OF SOOT OR CREOSOTE. APPLIANCE FLUE MUST BE IN GOOD CONDITION.

9.

STORE ALL FUEL OR COMBUSTIBLES OUTSIDE OF THE CLEARANCES LISTED AS

“CLEARANCE TO COMBUSTIBLES”

10.

IN THE EVENT OF A POWER FAILURE KEEP FIRE LOW - CLOSE DRAFT AIR, REMOVE

BLOWER CABINET DOOR AND AIR FILTERS TO ASSIST FLOW - OPEN ALL REGISTERS.

11.

SYSTEM SHOULD BE INSTALLED AND INSPECTED ANNUALLY BY A QUALIFIED PERSON.

12.

DISCONNECT POWER BEFORE SERVICING.

13.

“MAINTAIN COMBUSTION AIR TO BOTH FURNACES - AIR STARVATION IS DANGEROUS”.

14.

A FRESH AIR OPENING OF AT LEAST 3.3 mm

2

/w (1 1/2 in

2

/ 1000btu/h) SHALL BE PROVIDED.

APPROVED ELECTRICAL COMPONENTS:

THERMOSTAT -

WHITE RODGERS : 1E78-140

DAMPER MOTOR -

HONEYWELL: M847A1049B OR WHITE RODGERS 2070-5

FAN LIMIT(3) -

WHITE RODGERS: 5D51-78

CERTIFIED TO / CERTIFIÉE SELON: CSA Std B366.1-11

MODEL MP-80 LISTED SOLID FUEL FURNACE

MADE IN CANADA BY

Valley Comfort Systems Inc.

1290 Commercial Way, Penticton, BC, V2A 3H5

DO NOT REMOVE

THIS LABEL

SERIAL WH

CETTE UNITÉ PEUT ÊTRE INSTALLEE COMME INDIQUÉ CI-DESSOUS:

1.

FOURNAISE INDEPENDANTE A CIRCULATION D’AIR PULSÉ EQUIPPÉE D’UN VENTILATEUR

HAC 900 CFM, COMME DÉMONTRÉ DANS LE DIAGRAMME “A’ CI-DESSOUS.

2.

SÉRIE FOURNAISE COMBINÉE AVEC CONDUITS EN AVAL, EN COMBINAISON AVEC

N’IMPORTE QUELLE DES FOURNAISES SUIVANTES:

A.

FOURNAISE A MAZOUT AYANT UNE CONSOMMATION DE MAZOUT TEL QU’INDIQUE

SUR LA PLAQUE SIGNALETIQUE DU FABRICANT ORIGINAL, ENTRE .81 USGPH ET 1.2

USGPH (MAX) DIAGRAMME “B’.

B.

FOURNAISE A GAZ A CIRCULATION D’AIR FORCÉE AVEC UNE CAPACITE entre

60000 BTU Minimum et 120,000 BTU MAXIMUM (17-35 kW) , comme affi ché sur la

plaque signalétique, avec une augmentation de température de l’air entre 39-56°C(70-100°F).

LE VENTILATEUR Doit pouvoir fournir un débit de 900 CFM MINIMUM, DIAGRAMME “B’

C.

FOURNAISE ELECTRIQUE A AIR FORCÉE D’UNE PUISSANCE MINIMUM DE 10

KW A 25 KW, AVEC VENTILATEUR 900 CFM MINIMUM. DIAGRAM “B’.

EXIGENCES REQUISES POUR LA CHEMINÉE:

CHEMINEE POUR TOUT COMBUSTIBLE 29 po. ca. (1820 mm. ca.). NE PAS BRANCHER CETTE

FOURNAISE A UNE CHEMINÉE QUI EST DÉJÀ UTILISÉE PAR UN APPAREIL AU GAZ.

EXIGENCES ELECTRIQUES REQUISES:

120 V AC 15 A CRKT. CONTROL DU VENTILATEUR 2000 VA.

DÉGAGEMENTS MINIMUM:

EXTRIMITÉ POUR LE CHARGEMENT DU BOIS

48 po.

(1200 mm)

UN

COTE

6

po.

(150

mm)

COTE OPPOSE (POUR L’ENTRETIEN)

18 po.

(460 mm)

TUYAU

(MATERIAUX COMBUSTIBLES, FIL ELECTRIQUE

ET FOURNAISE ELECTRIQUE)

18 po.

(460 mm)

PLENUM ET 6 PREMIERS PIEDS DE TUYAU

2 po.

(50 mm)

DIMENSION MINIMUM DU RACCORDEMENT DES TUYAUX 12 po. (300 mm) x 18 po. (460 mm). NOTE

- PAS APPROUVE POUR PLENUM PARALLELE OU DIVISÉ (SÉRIE DES COMBINÉS APPROUVÉS

SEULEMENT). SI INSTALLÉ SUR UN PLANCHER COMBUSTIBLE ON DOIT AJOUTER UN PROTECTION

DE PLANCHER MINIMUM 18 po. (460 mm) EN AVANT DE L’APPAREIL SECTION DU CHARGEMENT.

VOIR INSTRUCTIONS D’INSTALLATION.

INSTALLEE PAR

ADRESSE

DATE

INSTRUCTIONS DE FONCTIONNEMENT:

VOIR INSTRUCTIONS DÉTAILLÉES DU FABRICANT.

1.

BRULER DU BOIS SEULEMENT.

2.

CHARGER LE BOIS AVEC PRUDENCE AFIN D’EVITER DES DOMMAGES.

3.

NE PAS CHARGER LE BOIS PLUS HAUT QUE LE BAS DE LA PORTE DE CHARGEMENT.

4.

NE PAS ALLUMER UN FEU S’IL Y A DES VAPEURS DE MAZOUT, GAZ À PROXIMITE DE LA

FOURNAISE.

5.

NE PAS EMPLOYER DES PRODUITS CHIMIQUES OU DES FLUIDES POUR ALLUMER LE FEU.

ATTENTION:

1.

NE PAS RACCORDER DE CONDUITS DE SORTE QU’UN FLUX REVERSIBLE SOIT POSSIBLE.

2.

FAIRE FONCTIONNER LA FOURNAISE HUILE/GAZ/ÉLECTRIQUE PÉRIODIQUEMENT AFIN DE

VOUS ASSURER QU’ELLE FONCTIONNERA ADÉQUATEMENT LORSQUE NÉCESSAIRE.

3.

NE PAS RELOCALISER OU CONTOURNER LES CONTRÔLES DE SÉCURITÉ À L’INSTALLATION

DE LA FOURNAISE ORIGINALE.

4.

DÉBRANCHER LE COURANT ÉLECTRIQUE FOURNAISE AU BOIS ET ÉLECTRIQUE/GAZ/HUILE

AVANT DE FAIRE L’ENTRETIEN.

5.

NE PAS BRÛLER DE REBUT, NAPTHA, GAZ, HUILE MOTEUR EN AUCUN CAS.

6.

GARDER LA PORTE DE CHARGEMENT HERMÉTIQUEMENT FERMÉE.

7.

EN CAS D’UN FEU HORS DE CONTROLE OU UN FEU DE CHEMINEE, FERMER TOUTES

LES ENTREES D’AIR DE LA FOURNAISE. POUR FERMER LE REGISTRE D’AIR A LA MAIN,

DÉCROCHER LA CHAINE DU VOLET DU REGISTRE APPELER LES POMPIERS ET SE

PREPARER A QUITTER LA MAISON, AVANT DE COMMENCER UN AUTRE FEU DANS LA

FOURNAISE, CORRIGER LE PROBLEME.

8.

NETTOYER REGULIEREMENT LES CONDUITS DE CHALEUR, LES TUYAUX ET LA CHEMINEE

AFIN D’EVITER LA FORMATION DE CREOSOTE IL FAUT GARDER LES TUYAUX ET LA

FOURNAISE. EN BONNE CONDITION DE FONCTIONNEMENT.

9.

REMISER LE BOIS ET TOUT AUTRE MATERIAU COMBUSTIBLE EN RESPECTANT

LES DÉGAGEMENTS NOTEES COMME “DEGAGEMENTS MINIMUMS DE MATERIAUX

COMBUSTIBLES’.

10.

EN CAS DE PANNE D’ELECTRICITE GARDER LE FEU FAIBLE - FERMER L’ACCES

D’AIR. ENLEVEZ LA PORTE DU VENTILATEUR ET LES FILTRES D’AIR POUR AIDER A LA

CIRCULATION D’AIR. OUVRIR TOUS LES REGISTRES.

11.

LE SYSTEME DOIT ETRE INSTALLE ET INSPECTÉ TOUS LES ANS PAR UNE PERSONNE

QUALIFIEE.

12.

COUPER L’ALIMENTATION DU COURANT AVANT DE FAIRE L’ENTRETIEN DE LA FOURNAISE.

13.

IL FAUT FOURNIR D’AIR A COMBUSTION AUX DEUX FOURNAISES EN TOUT TEMPS.

14.

IL FAUT FOURNIR UNE OUVERTURE D’AIR FRAIS D’AU MOINS 3.3 mm

2

/w (1 1/2 po

2

/ 1000btu/h)

COMPOSANTS ELECTRIQUES APPROUVÉS:

THERMOSTAT -

WHITE RODGERS: 1E78-140

MOTEUR DU VOLET -

HONEYWELL : M847A1049B OU WHITE RODGERS 2070-5

LIMITE / VENTILATEUR(3) -

WHITE RODGERS: 5D51-78

DIAGRAM B

DIAGRAM A

4011009

CERTIFICATION LABEL

Содержание MP80

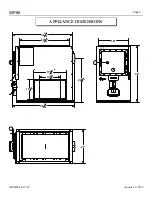

Страница 5: ...OM MP80 E V1 15 January 29 2015 Page 5 MP80 APPLIANCE DIMENSIONS...

Страница 34: ...OM MP80 E V1 15 January 29 2015 Page 34 MP80 NOTES...

Страница 35: ...OM MP80 E V1 15 January 29 2015 Page 35 MP80 NOTES cont...

Страница 36: ...OM MP80 E V1 15 January 29 2015 Page 36 MP80 NOTES cont...