OM-MP80 E V1.15

January 29, 2015

Page 12

MP80

INSTALLATION INSTRUCTIONS cont.

CLEARANCE TO COMBUSTIBLE MATERIALS / PLENUM AND VENTING INSTALLATION

•

ALL PLENUM DUCTING AND VENTING INSTALLATION MUST CONFORM WITH CAN/CSA B365-01. THE

WARM AIR SUPPLY DUCT AND THE PLENUM SHALL BE CONSTRUCTED OF METAL. ALWAYS CHECK

LOCAL BUILDING AND FIRE CODES, AND AUTHORITIES HAVING JURISDICTION.

•

ALL PLENUM, DUCTING AND VENTING MUST BE INSTALLED BY A QUALIFIED / LICENSED INSTALLER.

•

DO NOT USE MAKESHIFT COMPROMISES DURING INSTALLATION. DO NOT BLOCK OR RESTRICT AIR.

DO NOT IMPEDE AIR MOVEMENT IN ZONES MARKED “CLEARANCE TO COMBUSTIBLES”.

FLUE / CHIMNEY

•

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE EXCEPT

WHEN IN A WOOD / OIL CONFIGURATION

•

USE CHIMNEY CERTIFIED TO 2100°F (1149°C) FOR WOOD BURNING APPLIANCES, LISTED AS

UL 103HT (USA), ULC S629(CANADA) MINIMUM 6” (152 MM) DIAMETER LISTED RESIDENTIAL

CHIMNEY. SEE AND FOLLOW CHIMNEY MANUFACTURES INSTRUCTIONS.

•

CHIMNEY DRAFT GREATER THAN -0.06” W.C. (-15 PA) MAY CAUSE AN UNCONTROLLABLE FIRE

AND DAMAGE THE FURNACE.

Appliance connector shall be 24 ga black iron pipe, 24 ga stainless steel pipe or double wall smoke pipe

installed as per B365-10 or manufactures certifi ed instructions. NOTE: double wall pipe requires the use

of a stove adapter and a tee to provide for a barometric damper.

CONTROLLING DRAFT

Barometric dampers can be installed to maintain normal operating draft between 0.03” and 0.06” W.C

(10 Pa and 15 Pa).

•

IF OPERATING DRAFT RANGE IS EXCEEDED IT CAN CAUSE SOLID FUEL FIRE TO BURN OUT

OF CONTROL CREATING OVER FIRE CONDITION, SEE “RUN-AWAY OR CHIMNEY FIRE” on page

25.

•

STRICTLY ADHERE TO ALL IDENTIFIED INSTALLATION CLEARANCES.

MEASURING DRAFT

Using a manometer with appropriate scale range connect testing tube between manometer and chimney

connector. End of testing tube should be inserted in chimney connector so approximately 1” (25

mm) of tube protrudes into and perpendicular to exhaust stream. Th

is measurement shall be taken

approximately 12” (305 mm) above elbow/T attached to the furnace fl ue. Any hole made in the chimney

connector for insertion of manometer tube shall be adequately sealed with high temp materials when

testing is complete. Chimney draft to be a minimum -0.03” W.C. (-10 Pa) to maximum -0.06” W.C. (-15

Pa).

Содержание MP80

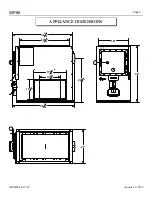

Страница 5: ...OM MP80 E V1 15 January 29 2015 Page 5 MP80 APPLIANCE DIMENSIONS...

Страница 34: ...OM MP80 E V1 15 January 29 2015 Page 34 MP80 NOTES...

Страница 35: ...OM MP80 E V1 15 January 29 2015 Page 35 MP80 NOTES cont...

Страница 36: ...OM MP80 E V1 15 January 29 2015 Page 36 MP80 NOTES cont...