13

Operating and Installation Manual for uniSTOR, auroSTOR, geoSTOR Cylinders 0020080043_00

1

2

3

4

6

7

5

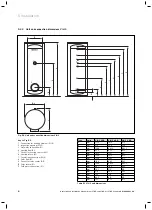

Fig. 5.12 Installing the safety groups

Key to Fig. 5.12

1 Venting

knob

2 Blow-off

line

3 Stop

valve

4 Stop valve with hand wheel

5 Test

plug

6 Pressure gauge connection point

7 Backflow

preventer

6 Start-up

Once installation is complete, the cylinder must be filled

on the heating and DHW sides. Proceed as follows to do

this:

• VIH S only: Fill the solar circuit (see System Manual).

• Fill the heating side via the boiler filling and draining

connection.

• Check the cylinder and system for leaks.

• Fill the DHW system via the cold water inlet and bleed

the system at a hot water draw-off point.

• Check the function and correct setting of all control

and monitoring devices.

• Program the timer or timer program, if present, on

the controller (define the start of the enable time for

cylinder charging).

• Put the boiler into operation.

• VIH S only: Put the solar system into operation.

6.1 Regulations

Observe all applicable national regulations and guide-

lines.

Before the installation, check if there are further local

regulations.

7 Maintenance

7.1

Cleaning the internal tank

Make sure the cleaning devices and cleaning agents are

in a hygienic condition, since the cleaning work is car-

ried out in the inner tank of the cylinder within the

drinking water area.

Proceed as follows when cleaning the inner tank:

• Drain the cylinder.

• Remove the flange cover on the cleaning eye.

• Clean the cylinder with a jet of water. If necessary,

loosen any deposits with a suitable tool e.g. a wood or

plastic scraper and flush them out.

h

Note!

Ensure that the enamelling of the heating coil

and the inner tank is not damaged during the

cleaning work.

• Replace the flange cover with its associated gaskets

on the cleaning eye of the cylinder.

• Tighten the screws.

h

Note!

You must replace any old or damaged seals.

• Fill the cylinder and check for leaks.

H

Danger!

Risk of being scalded by hot water!

The blow-off line on the expansion relief valve

fitted to the DHW cylinder must remain open at

all times.

Check the function of the expansion relief valve

during servicing by venting it.

If this is not done, the possibility of the cylin-

der bursting cannot be ruled out!

7.2

Servicing the magnesium sacrificial anode

The cylinder is fitted with a magnesium sacrificial anode

which has an average service life of approx. 5 years.

To service the anode, the plastic cover must be re-

moved and the anode released with a 27 mm AF box

spanner or socket.

Visual inspection

• Remove the magnesium sacrificial anode (

1

) and check

it for erosion.

Installation 5

Start-up 6

Maintenance 7

Содержание uniSTOR

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ...0020080043_00 EXP 062009 Subject to alterations...