3

Operating and Installation Manual for uniSTOR, auroSTOR, geoSTOR Cylinders 0020080043_00

2

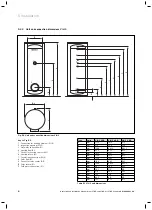

Description of the appliance

2.1 Construction

and

function

Vaillant VIH S 300/400/500 solar cylinders are used as

indirectly heated DHW cylinders for solar-assisted hot

water generation.

Vaillant VIH R 300/400/500 cylinders are indirectly

heated DHW cylinders.

Vaillant VIH RW 300 cylinders are indirectly heated

DHW cylinders intended specifically for heat pumps.

The cylinders and the pipe coils are enamelled on the

DHW side to ensure long service lives. Each tank has a

magnesium sacrificial anode for additional corrosion

protection. A maintenance-free external current anode

is available as an accessory.

The CFC-free EPS insulation provides the best thermal

insulation.

Furthermore, an electric heating element (accessory)

can be installed in the cylinders (except for the

VIH RW 300) to support post-heating, so that post-heat-

ing by the boiler can be completely dispensed with in

summer operation.

The heat is transferred by means of one (VIH R, RW) or

two (VIH S) welded-in coiled pipes.

The cylinder is connected to the water mains via the

cold water connection and to the draw-off points via the

hot water connection. If hot water is run from one of

the draw-off points, cold water will flow into the cylinder

where it is heated up to the temperature set on the cyl-

inder temperature controller.

VIH S only

In VIH S type solar cylinders, the heating takes place in

two separate circuits.

The solar heat exchanger is located in the lower, cold

area. The relatively low water temperatures in the bot-

tom area ensure optimum heat transfer from the solar

circuit to the storage water even if there is only a low

level of solar radiation.

In contrast to solar heating, the hot water is post-heat-

ed by the boiler or circulation water heater in the upper,

warmer zone of the cylinder. The standby volume for

post-heating is about a third of the cylinder volume.

2.2 Conformity

with

Directives

We confirm that our product is manufactured in accord-

ance with the EU Pressure Equipment Directive.

2.3 Model

overview

The cylinders are available in the following sizes:

VIH S

Cylinder volume

VIH S 300

289 litres

VIH S 400

398 litres

VIH S 500

484 litres

Table 1.1 VIH S model overview

VIH R

Cylinder volume

VIH R 300

295 litres

VIH R 400

404 litres

VIH R 500

496 litres

Table 1.2 VIH R model overview

VIH RW

Cylinder volume

VIH RW 300

285 litres

Table 2.3 VIH RW model overview

2.4 Identification

plate

An identification plate has been fixed to the top of the

casing at the factory.

3

Safety instructions and regulations

Vaillant VIH S, VIH R and VIH RW cylinders are con-

structed using state-of-the-art technology in accordance

with recognised safety regulations. Nevertheless, there

is still a risk of injury or death to the user or others or

of damage to the unit and other property in the event of

improper use or use for which they are not intended.

a

Caution!

The units may only be used to heat up drinking

water. Damage to the appliance due to corro-

sion cannot be excluded if the water does not

correspond to the specifications of the drinking

water ordinance.

3.1 Safety

instructions

The VIH S 300/400/500 solar cylinders and

VIH R 300/400/500 and VIH RW 300 cylinders must be

installed by a qualified heating engineer, who is respon-

sible for compliance with existing regulations, rules and

directives.

We only honour the manufacturer’s warranty if the in-

stallation is performed by an approved qualified servic-

ing company which is also responsible for the inspec-

tion/maintenance of, and repairs and alterations to the

cylinders.

Safety valve and blow-off line

The water volume is increased each time the hot water

is heated in the cylinder, which is the reason why each

cylinder must be equipped with an expansion relief valve

and an exhaust line.

Description of the appliance 2

Safety instructions and regulations 3

Содержание uniSTOR

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ...0020080043_00 EXP 062009 Subject to alterations...