0020285063_05 Installation and maintenance instructions

11

Maximum length of the air pipes L1 + L2 (L1 = air in-

take pipe; L2 = air outlet pipe)

Condition:

Fixed pipes

20 m

Note

In addition to the total

length, two 90° el-

bows can be added.

Note

In an installation with rigid pipes, elbows, at-

tachments and mesh create additional pres-

sure losses in the air duct system that may

correspond to five metres of straight pipe

length per element. Make sure that the max-

imum permitted lengths are not exceeded

with the elements used.

2.

Protection devices must be installed at the openings

of the air ducts to prevent water or foreign bodies from

penetrating the pipelines (protective grille for vertical

walls, roof terminals).

3.

Always protect the product against modification or

intervention in order to prevent water or foreign sub-

stances from penetrating as this may damage the

pipes or other components.

4.

Use a circulation pump with a throughput between 0.5

and 4 l/min.

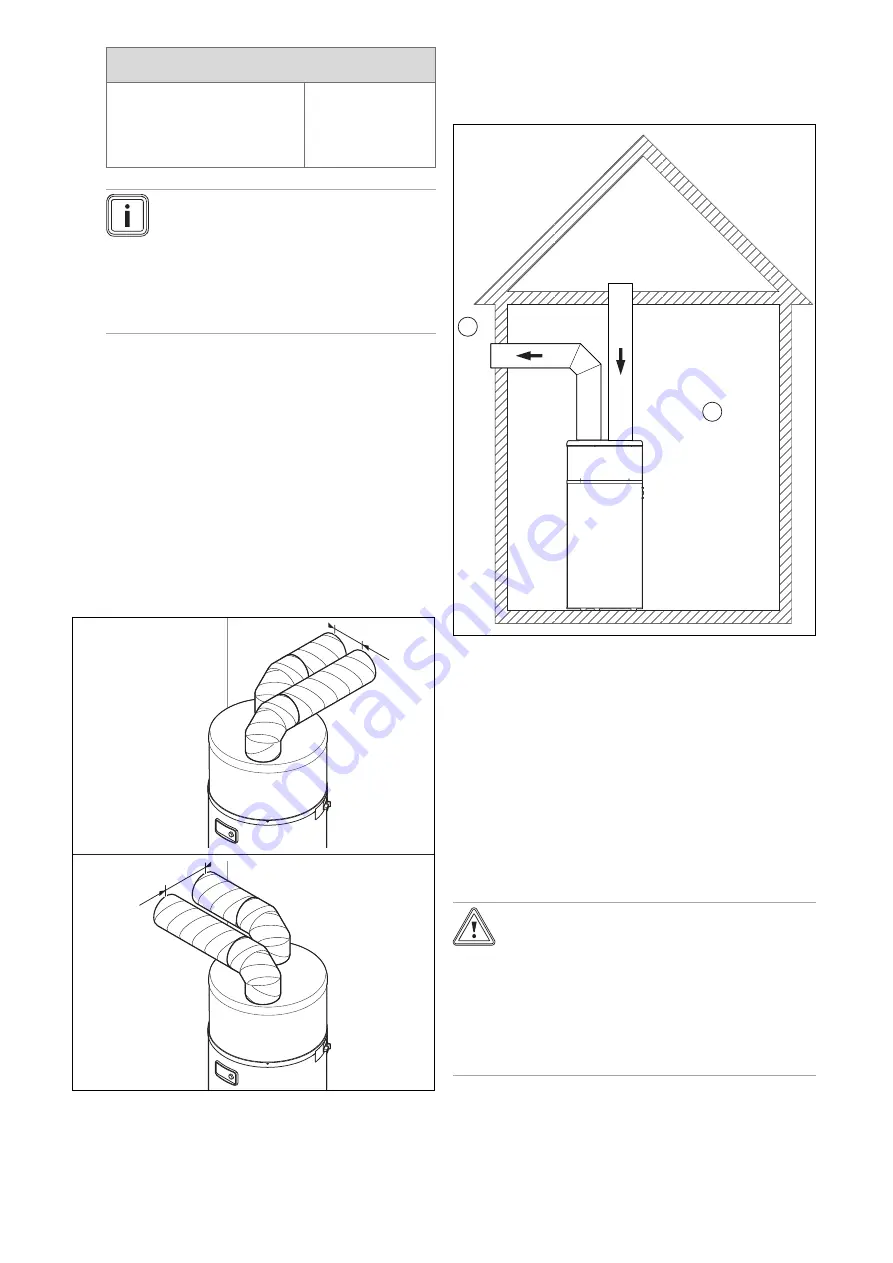

5.1.2

Installing the complete pipe system

Complete pipe system

The air inlet and outlet are located in the external area.

220

292

This installation type is particularly suitable for small rooms

(supply or store room, etc.).

This configuration prevents a room from being cooled and

does not impair ventilation.

▶

In order to prevent leak air from being extracted by recir-

culation, maintain a clearance between the ends of the

air pipes.

–

Clearance:

≥

220 mm

1

2

Complete pipe system

1

External area

2

Internal area (heated or

not heated)

5.1.3

Installing the partial pipe system

Partial pipe system

The hot air is drawn into the room and the cold air is

released outside.

With this installation type, the room is used as an energy

collector. The room is cooled by outdoor air which flows in

via the ventilation openings.

–

Room volume at installation site:

≥

20 m

³

Caution.

Risk of material damage due to condensa-

tion forming on the outside of the pipe.

The difference in temperature between the

air flowing through the pipe and the air in the

installation room can cause condensation to

form on the outside surface of the pipe.

▶

Use air pipes with suitable heat insulation.

▶

Avoid having negative pressure in the installation room,

so that air is not extracted from surrounding heated

rooms.

▶

Check whether the existing ventilation can compensate

for the withdrawn air flow.