VAG Operating and Maintenance Instructions • 4

4.2 Installation location

The installation location of the valve must provide enough space

for operation, later function tests and maintenance works (e.g. re-

adjusting the lateral seal). If the valve is to be installed outside, it

has to be protected by adequate covering against direct weather

influences such as icing. If the valve is mounted as an overflow

installation, higher operation forces and higher wear and tear of

the relatively moving parts must be expected. This fact is to be

taken into account when determining the maintenance intervals

If the valve is to be installed at pipeline end, make sure that the

free outlet is absolutely inaccessible for anybody.

Warning!! The nominal pressure on the closed valve must not be

exceeded (see document KAT 2410-A). In case of a pressure test

in the pipeline using higher pressures than the admissible nomi-

nal pressure, close the gate valve with a cover and slightly open

the knife during the test.

4.3 Installation position

If the valve is to be installed in a horizontal pipeline and if the

media conveyed contain solid particles (e.g. sand, etc.), the valve

should not be inclined more than 60° from the vertical position

(see Fig. 2). This allows the continuous flushing of the operating

area and reliable guiding of the knife.

In different installation positions, especially if the valve is sus-

pended or installed horizontally in a vertical pipeline, increased

deposition of solids on the knife cannot be avoided. This increa-

ses the risk of malfunction (e.g. wear of the lateral seal, increa- sed

operating forces, etc.) and requires more frequent maintenance.

Attention:

To ensure its proper function at all times, the

valve should not be installed outside the permissible range.

In case of deviating installation positions, always contact

the manufacturer for technical coordination, providing pre-

cise information about the installation position, operating

conditions and quality of the medium (especially about its

solids content).

If assembly and maintenance work are carried

out on valves with a suspended installation positi-

on, the knife must be secured on site against fal-

ling out when the lateral seal is being replaced.

Attention! Exception!

VAG ZETA

®

control valve with VAG control orifice. The ZETA

®

control

valve must be installed in a vertical position as otherwise its func-

tion may be affected by the accumulation of dirt upstream of the

control orifice.

Concerning the installation direction of the ZETA

®

control valve,

the following instructions must be observed:

• The control orifice must be positioned in flow direction

downstream of the knife!

• The control orifice must be positioned in pressure direction

(direction of action of the differential pressure after closing)

downstream of the knife!

3.2 Applications

In its standard version, the VAG ZETA

®

Knife Gate Valve with NBR

sealing material can be used for the following media:

• Water, raw water, cooling water, municipal waste water,

grease- and oil-containing media, weak acids and bases

For alternative operating conditions and applications, please con-

tact the manufacturer.

3.3 Permissible and impermissible modes of

operation

Avoid the exertion of excessive force caused by using ex-

tensions on the operating elements, as this may dama- ge

the valve due to overload.

The ZETA

®

Knife Gate Valve with electric multiturn actuator

is suitable for „Open/Close“ operation. For special control

applications, special versions such as the ZETA

®

control

with control orifice are required.

The maximum operating temperatures and operating pressures

specified in the technical documentation must not be exceeded.

The closed knife gate valve must not be exposed to pressures ex-

ceeding its nominal pressure (see Table 3 / nominal pressure PN).

Upon delivery, the tight sealing of the valve is only guaran- teed

up to its maximum permissible operating pressure.

The valve has been designed for operation in liquids. If it

is operated temporarily in dry media, increased operating

forces as well as increased wear of the lateral seal and the

U-profile seal are to be expected. Permanent dry operation

is impermissible for technical reasons!

4 Installation into the pipeline

4.1 Conditions required on site

When installing the valve between two pipeline flanges, these must

be coplanar and in alignment. If the pipes are not in align- ment,

they must be aligned before installation of the valve, as otherwise

this may result in impermissibly high loads acting onto the valve

body during operation and eventually even lead to fracture.

The valve is to be installed tensionless into the pipeline. No pipe-

line forces must be transmitted from the pipeline onto the valve.

The space between the flanges should be wide enough to prevent

damage to the coating of the flange gasket frames during instal-

lation.

In case of works around the valve causing dirt (e.g. painting, ma-

sonry or working with concrete), the valve must be protected by

adequate covering.

Picture 1: Example of a label showing the adjustments of the electric actuator

Factory-adjusted drive!!!!

Unauthorised changes result in

the loss of warranty

Position dependent

Torque-dependent

Torque adjusted

Control

Open

Closer

60 °

60 °

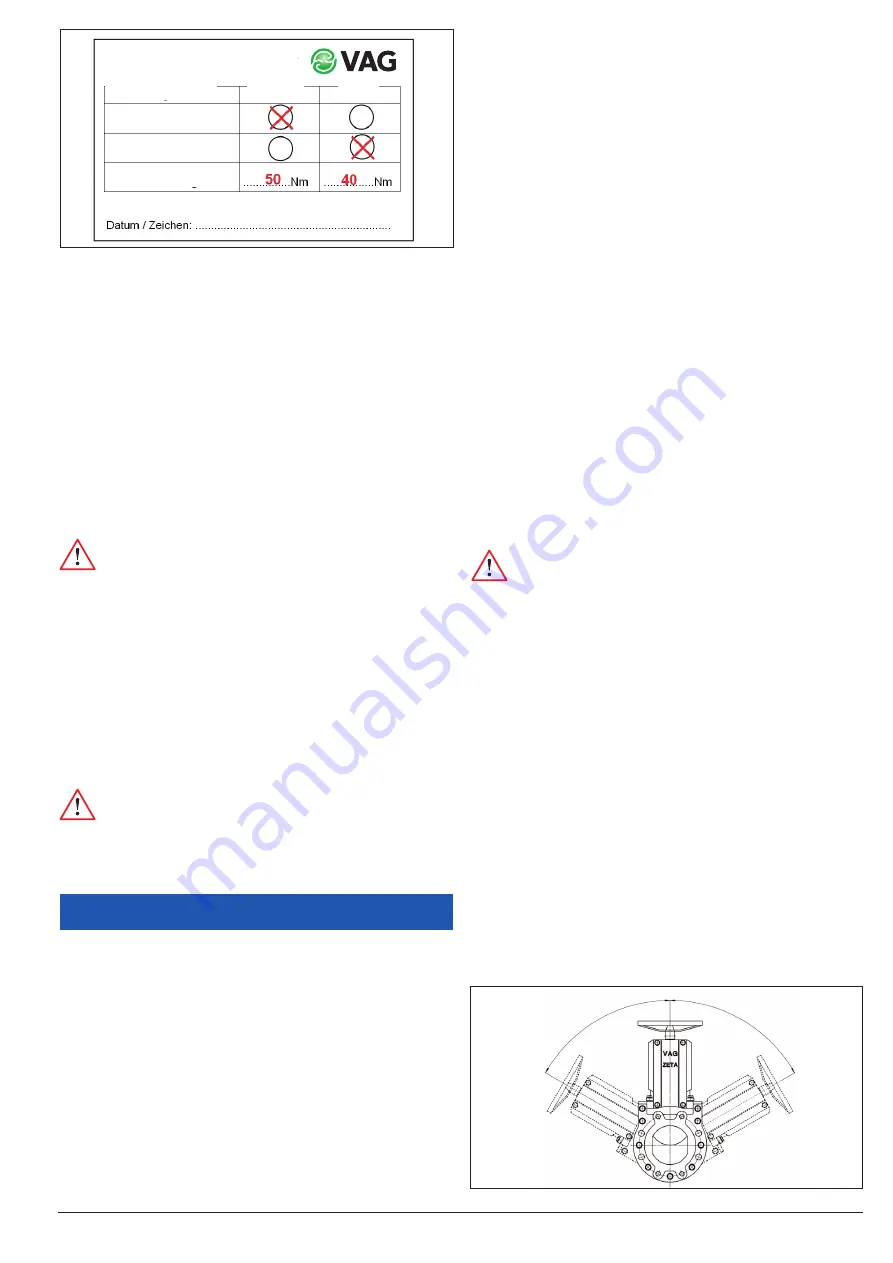

Picture 2: Installation position of the VAG ZETA

®

Gate Valve