7

7

3

3

Braking

Braking System

System

The braking system includes operation of the hand brake and foot brake. The hand brake

The braking system includes operation of the hand brake and foot brake. The hand brake

consists of a lever and cable; the foot brake consists of a brake pedal, brake master cylinder,

consists of a lever and cable; the foot brake consists of a brake pedal, brake master cylinder,

lines and brakes, etc.

lines and brakes, etc. The brakes are maintenance-free wet disc

The brakes are maintenance-free wet disc brakes.

brakes.

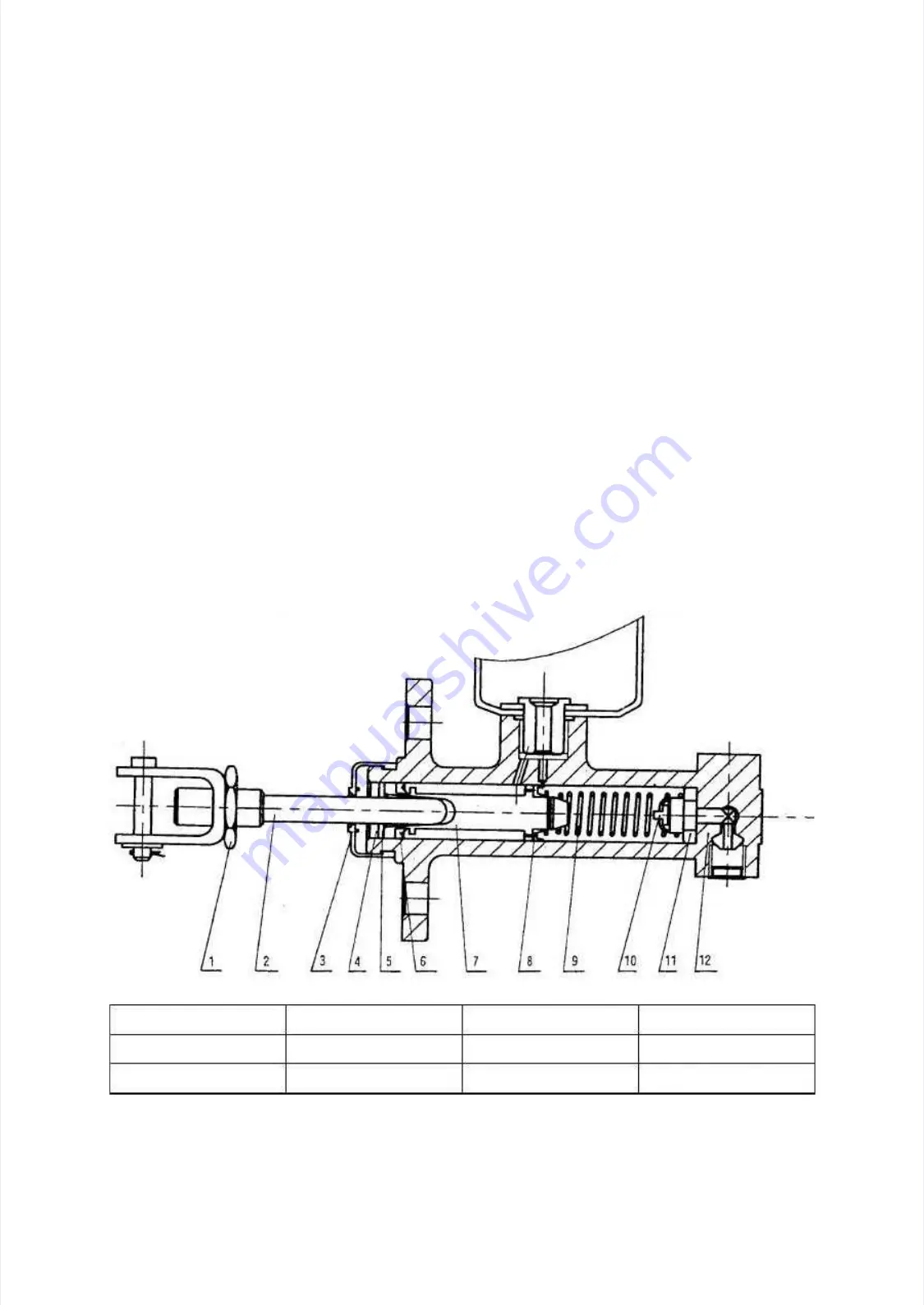

Brake master cylinder

Brake master cylinder

The brake master cylinder consists of a valve seat, check valve and return spring, as well as a

The brake master cylinder consists of a valve seat, check valve and return spring, as well as a

cup piston and auxiliary cup. The end

cup piston and auxiliary cup. The end part is secured using a snap washer and retaining wire, the

part is secured using a snap washer and retaining wire, the

outer part is protected by a rubber dust cover, and the master cylinder piston is actuated by the

outer part is protected by a rubber dust cover, and the master cylinder piston is actuated by the

brake pedal via a pushrod. When the brake pedal is depressed, the pushrod pushes the piston

brake pedal via a pushrod. When the brake pedal is depressed, the pushrod pushes the piston

forward and the brake fluid in the pump flows back to the reservoir via the return port until the

forward and the brake fluid in the pump flows back to the reservoir via the return port until the

main cup blocks the return port. Once the main cup pushes past the return port, the brake fluid in

main cup blocks the return port. Once the main cup pushes past the return port, the brake fluid in

the front chamber of the master cylinder is compressed and opens the check valve, thereby

the front chamber of the master cylinder is compressed and opens the check valve, thereby

flowing through the brake line to the wheel cylinders. This forces each wheel cylinder piston

flowing through the brake line to the wheel cylinders. This forces each wheel cylinder piston

outward so that the

outward so that the brake shoe friction plate contacts the brake drum, thus causing the

brake shoe friction plate contacts the brake drum, thus causing the vehicle to

vehicle to

decelerate or brake. At this point, the piston's rear chamber is replenished with brake fluid from

decelerate or brake. At this point, the piston's rear chamber is replenished with brake fluid from

the return and inlet ports. When the brake pedal is released, the pistons are forced back by the

the return and inlet ports. When the brake pedal is released, the pistons are forced back by the

pressure of the return spring. At the same time, the brake shoe return spring forces the brake fluid

pressure of the return spring. At the same time, the brake shoe return spring forces the brake fluid

in each brake wheel cylinder back through the check valve to the master cylinder (the front

in each brake wheel cylinder back through the check valve to the master cylinder (the front

chamber of the piston). The piston returns to

chamber of the piston). The piston returns to its original position and the brake fluid in the

its original position and the brake fluid in the master

master

cylinder flows back through the return port into the tank. The pressure of the check valve is

cylinder flows back through the return port into the tank. The pressure of the check valve is

adjusted until it reaches a certain ratio of the residual pressure in the brake line and brake wheel

adjusted until it reaches a certain ratio of the residual pressure in the brake line and brake wheel

cylinders, so as to correctly position the wheel cylinder cups to prevent oil leakage, as well as

cylinders, so as to correctly position the wheel cylinder cups to prevent oil leakage, as well as

eliminate the possibility of air

eliminate the possibility of air resistance during hard braking.

resistance during hard braking.

1.

1. Lock

Lock nut

nut

2.

2. Pushrod

Pushrod

3.

3. Dust

Dust cover

cover

4.

4. Retaining

Retaining wire

wire

5.

5. Retaining

Retaining washer

washer

6.

6. Auxiliary

Auxiliary cup

cup

7.

7. Piston

Piston

8.

8. Main

Main cup

cup

9.

9. Spring

Spring

10.

10. Check

Check valve

valve

11.

11. Valve

Valve seat

seat

12.

12. Pump

Pump body

body

Figure

Figure 3-1

3-1 Brake

Brake master

master cylinder

cylinder

https://www.forkliftpdfmanuals.com/