3

06-237172-001 Rev AA

June 2011

ROLLOUT SWITCH

Some control applications may have a separate rollout switch

directly connected to the old ignition control. In this case, the

rollout switch (normally closed) should be connected directly to

the THS terminal on the 35-63J. Verify the rollout switch is wired

in series (downstream) with the thermostat signal. The old THS

wire should be left unconnected and insulated to prevent the

possibility of a short-circuit.

VENT DAMPER CONNECTIONS

The 35-63J does not include an integral vent-damper connec-

tor. When replacing an older control (in applications using a

vent damper) that has a standard 6-pin vent damper plug, the

vent damper wires from the plug must be re-terminated and

connected as follows:

Note:

If the old control has a vent damper plug (with a

jumper between pins 2 and 3), but the heating appli-

ance has no vent damper, then ignore this section.

•

To connect the Vent Damper, the wire from Pin 1 should be

connected to 24VAC Hot from the supply transformer.

•

The wire from pin 2 should be connected to the Thermostat

input (THS) on the 35-63J control. This should be the only

wire attached to the THS terminal.

•

The wire from Pin 4 connects directly to the 24VAC Com-

mon.

•

The wire from pin 5 should be connected directly to the

Thermostat (call for heat signal) and not to the 35-63J

control.

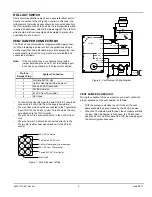

Figure 1. Wire Sideview of Plug

Figure 2. Vent Damper Wiring Diagram

VENT DAMPER CHECKOUT

During the checkout of the new control, you must confirm the

proper operation of the vent damper as follows:

•

With the system in standby (no call for heat) the vent

damper should be driven closed by the 24 VAC power.

•

When the Thermostat calls for heat, the vent damper starts

to open. After the damper is fully open, the 35-63J then

sees the 24 VAC call for heat at the THS input and begins

the normal ignition sequence.

Pin # on

Damper Plug

System Connection

1

Full-time 24VAC Hot

2

Call for Heat signal (from damper)

3

Fused 24 VAC (not used)

4

24VAC Common

5

24 VAC from Thermostat

6

Not Used

24 VAC Common

Full -time 24 VAC Hot

Call for Heat signal (from damper)

24 VAC from Thermostat

Fused 24 VAC (Not Used)

Not Used

4

1

5

2

6

3

Vent Damper

24 VAC

5

4

2

1

Thermostat

Pilot Gas Valve

Main Gas

Valve

Pilot

H.V.

Sense

Blind_Term

GND

_GND

GND_

THS

PV

MV

35-63J