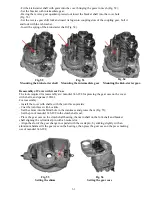

Fig. 61.

Mounting the driven gear of the

speedometer drive

Fig.57

Fig.58

Fig.59

Fig.60

345-943

- Set and tighten up seven bolts fastening the gear case cover, the tightening torque being

6.4

-

7.8 Nm

- Having turned the shaft for about 120 degrees anticlockwise by a wrench and sunk it in axial

direction to 8 mm minimum cock spring of the kick-starter and free the shaft. The shaft should

get out of the cover and lock (Fig.57).

- Set the gearshift sleeves in the neutral position by turning the reverse gear shift lever

backwards and check the shafts for ease of rotation;

- Fails the clutch shaft rotate easily, jump it into the hole for the slider, same with the main shaft

on the flexible coupling plate using mandrels (Fig.58 and 59).

- Check operation of starter mechanism and its spring.

The tolerable axial movement of the starter shaft is 1.0 mm.

- Press the plate onto the splines using device 345-943, fasten and splint (Fig. 60).

- Set the kick-starter lever, put distance washer onto the starter shaft, insert fastening wedge

knocking it with a aluminum hammer and tighten. The torque is 15.7

-

19.6 Nm.

For reassembly of the speedometer drive and clutch release mechanism refer to relevant sections

of this manual.

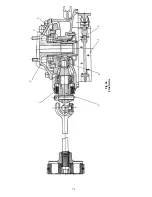

Fig. 62.

Setting the thrust bushing.

62

Содержание 750cc Series

Страница 1: ...Repair Manual 750cc All Models www imz ural com ...

Страница 2: ......

Страница 50: ...Fig 40 Removing the valve springs Fig 41 Measuring the side play between the valve and bush guide 50 ...

Страница 71: ...1 2 3 4 5 6 7 8 Fig 66 Final drive 71 ...

Страница 75: ...1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Fig 67 Final drive with disengageable sidecar drive 75 ...

Страница 98: ...Fig 11 iring Diagram 9 W 98 ...