CHAPTER 2: GENERAL SETUP

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

2-4

990-057

HF2 Welding System Maximum Secondary Loop Resistance

To use the HF2 Weld Control and HF2 Weld Transformer system to its maximum capability, the

Maximum Secondary Loop Resistance must not exceed the values listed in the preceding table.

Exceeding these maximums will produce a "FEEDBACK RANGE EXCEEDED" alarm.

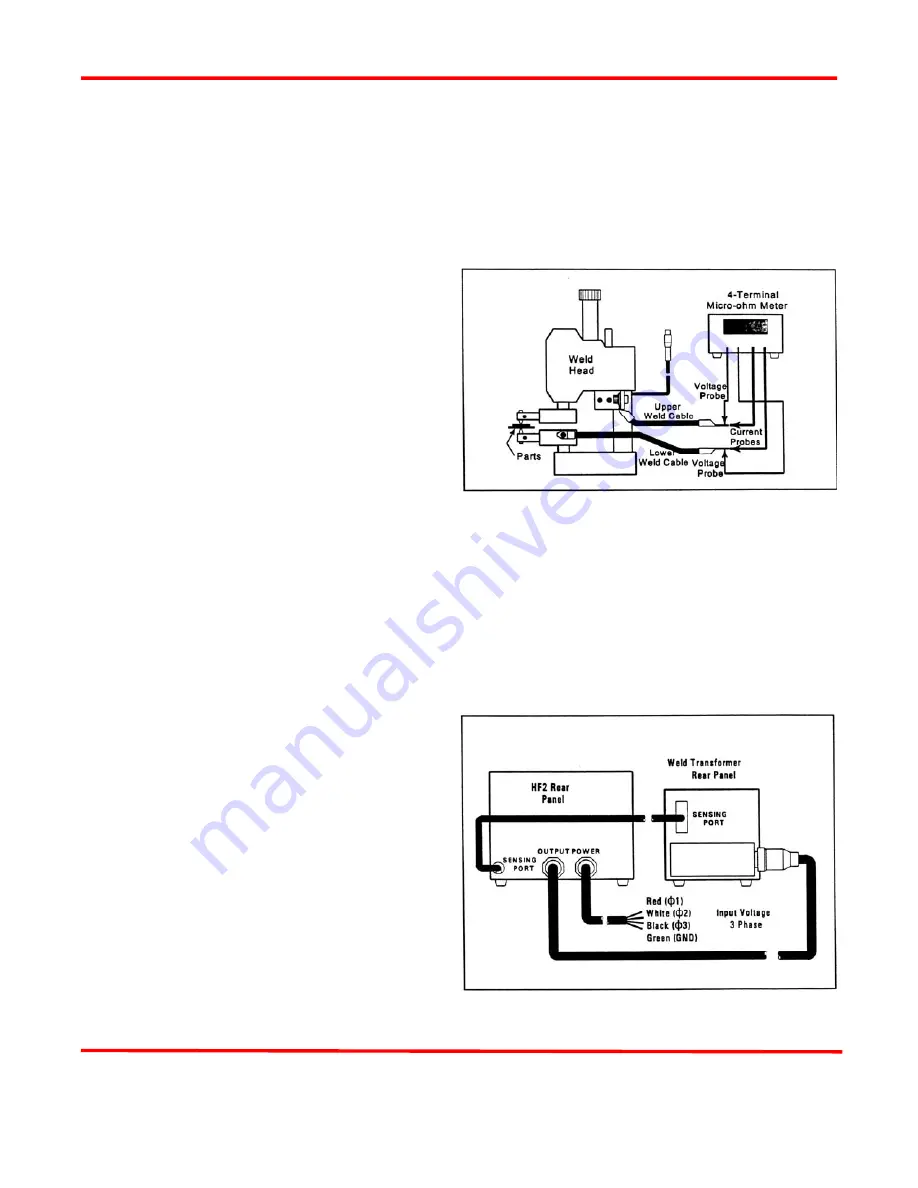

HF2 Maximum Secondary Loop Resistance Measurement (Figure 2-4)

1

Connect a four terminal micro-ohmmeter

as shown in Figure 2-4.

2

Put the parts to be welded between the

electrodes.

3

Measure the total loop resistance which

includes both Weld Cables, Weld Head,

Electrodes, and parts.

4

If the total loop resistance exceeds the

table value, use:

A)

Larger diameter Weld Cables

Figure 2-4. Secondary

Resistance Measurement

B)

Shorter length Weld Cables, or

C)

Copper Bus Bars to connect the HF2 Weld Transformer to the Weld Head. If these

suggestions do not work, then a different Weld Transformer Model may be required.

CAUTION:

For product safety, the system power cable and all inter-unit cabling should be as short as

possible, and be dressed so that all cables stay separated.

HF2 Weld Control to HF2 Weld Transformer Connections (Figure 2-5)

The HF2 Weld Control must always be connected

to the HF2 Weld Transformer as shown in Figure 2-

5, regardless of what Weld Head System is used.

1

Connect the HF2 Weld Control POWER

Cable to the line voltage source as

specified in

Chapter 2, Power Line

Voltage, Current, and Wire Size

Requirements.

2

Connect the HF2 Weld Control OUTPUT

Cable to the matching connector on the

HF2 Weld Transformer.

3

Connect the HF2 Weld Control SENSING

PORT Cable to the matching connector on

the HF2 Weld Transformer.