13

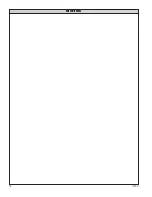

USSC

PARTS DIAGRAM AND LIST

38

45

44

46

48

40

37

36

39

41

42

43

47

49

IMPORTANT NOTE:

When ordering repair parts, a color code (G) should be placed

after the part number of any part that is painted.

Key Description

Part #

Qty

1

Feed Door Assy. (w/Rope Gasket)

69091

1

2

Door Handle

24179

2

N/S

Lock Nut, 1/2-13

83444

2

N/S

Washer

83835

2

3

Spring Handle

89574

4

4

Feed Door Latch

23786

1

5

Ash Door Assy. (w/Rope Gasket)

68880

1

6

Draft Cap

23859

2

N/S

Carriage Bolt, 3/8-16 x 2-1/2”

83835

2

7

Ash Door Latch

23823

1

N/S

Hinge Pin, 5/16” x 1”

C21399

4

8

Shaker Handle

69005

1

9

Bracket, Shaker Handle

24204

1

10

Ash Pan

68882

1

11

Grate Retainer

40312

2

12

Shaker Bar

891341

1

13

Shaker Grate Section

40314

5

14

Back Liner

40313

1

15

Front Liner

40344

1

16

Full Firebrick (4-1/2 wide x 9 tall x 1-1/4 thick)

89066

16

17

Half Firebrick (2-1/4 wide x 9 tall x 1-1/4 thick)

891414

3

18

Slide Baffle

24231

1

19

Baffle Rod

86603

1

20

Lock Nut, 1/2-13

83444

2

21

Gasket, Flue Collar

88032

1

22

Flue Collar

40246

1

23

Flue Collar Ring

22761

1

24

Smoke Curtain

23800

1

25

Smoke Door Clip

23787

2

26

Carriage Bolt, 1/4-20 x 1-1/4 Long

83445

2

27

Kep Nut, 1/4-20

83250

2

28

Cabinet Side, Left

69452

1

29

Cabinet Side, Right

69453

1

30

Blank Receptacle, Snap-In

891127

1

31

Cabinet Back

25624

1

32

Insulation, Panel

C98871

1

N/S

Insulation Retainer

83884

12

33

Cabinet Top

69088

1

34

Front Filler

23817

1

35

Draft Cover

23818

1

36

Room Blower - 800 CFM

80530

2

37

Blower Gasket

88127

2

38

Tinnerman Clip, 1/4-20

83340

8

39

Bolt, 1/4-20 x 3/4

83339

8

40

Conduit Assembly (5ft)

69578

2

41

Snap-disc, 140°F Adjustable

80388

1

N/S = Not Shown

Key Description

Part #

Qty

42

Snap-disc Box

68234

1

43

Conduit Assembly (1.5ft)

68231

1

44

Junction Box

25625

1

45

Insulation (5” x 5”)

25626

1

46

Junction Box Cover

80231

1

47

Rocker Switch

C42373

1

48

Romex Cable Clamp

80362

1

49

Water Coil Access Cover

23819

1

Содержание NITED STATES STOV 1602M

Страница 18: ...18 USSC NOTES ...

Страница 19: ...19 USSC NOTES ...