035-17438-001 Rev. A (901)

24

Unitary Products Group

REPLACEMENT OF THE VARIABLE SPEED

MOTOR WITH A MULTI-SPEED PSC DIRECT

DRIVE MOTOR

NOTE:

A failed variable speed motor should always be

replaced with a variable speed motor suitable for the furnace

model being serviced. However, if one is not available, a

multi-speed direct drive motor may be used in the interim.

REMOVAL OF THE VARIABLE SPEED BLOWER

ASSEMBLY AND MOTOR

Follow the Blower Removal Instructions in the Maintenance

section of this instruction under, “BLOWER CARE” on

page 21.

1.

Loosen the blower wheel set screw and the motor mount

bolt, and slide the variable speed motor out of the blower

housing.

INSTALLATION OF PSC MOTOR

1.

Install the PSC multi-speed direct drive motor into motor

mount. See table for proper motor and capacitor part

numbers. See Table 7.

2.

Slide motor in motor mount insuring there is no interfer-

ence between moving and stationary parts. Position wire

leads downward. Tighten motor mount screw to 30 in.

lbs.

3.

Center the blower wheel in the blower housing and align

the shaft flat with the blower wheel set screw. Tighten set

screw to 15 ft. lbs.

4.

Replace blower assembly and fasten with 3 screws

5.

Strap motor capacitor to electric panel. See Table 7.

6.

Fasten electric panel to blower housing.

7.

Remove red wire from Circ. input terminal. Plug jumper

wire (attached to motor power harness) on 120 volt line

terminal on ignition control and jumper to CIRC. INPUT

Connect brown door switch wire to jumper.

8.

Connect white main harness lead to Line neutral.

9.

Connect motor leads to cool, heat lo and heat high per

Table 6.

10. Connect brown capacitor leads from motor to capacitor

and cover terminals with boot supplied.

FURNACE CONTROL DIAGNOSTICS

The furnace has built-in, self diagnostic capability. If a system

problem occurs, a fault code is shown by a blinking LED. It is

located behind a clear view port in the blower compartment

door. DO NOT remove the furnace blower compartment

panel OR turn off furnace power as either action will clear the

control's memory of the fault.

The control continuously monitors its own operation and the

operation of the system. If a failure occurs, the LED will indi-

cate the failure code. If the failure is internal to the control, the

light will stay on continuously. In this case, the entire control

should be replaced as the control is not field repairable.

If the sensed failure is in the system (external to the control),

the LED will flash in the following flash-pause sequences to

indicate failure status.

Flash sequence codes 2 thru 8 are as follows. LED will turn

on for 1/4 second and off for 1/4 second. This pattern will be

repeated the number of times equal to the code. For exam-

ple, six on flashes equals a number 6 fault code.

All flash code sequences are broken by a 2 second off period.

POWER SUPPLY POLARITY - Ignition Control

If the power supply polarity is reversed, the following unit

operation will occur. On a call for heat, the inducer will

run, the HSI will glow and the gas valve will energize and

the burners will ignite. The burners will immediately

extinguish and the unit will recycle. This will occur 3

times and then the unit will lockout. A “7” flash code will

be displayed. This code means the flame could not be

established. This occurs because the control cannot

sense flame with the power supply polarity reversed.

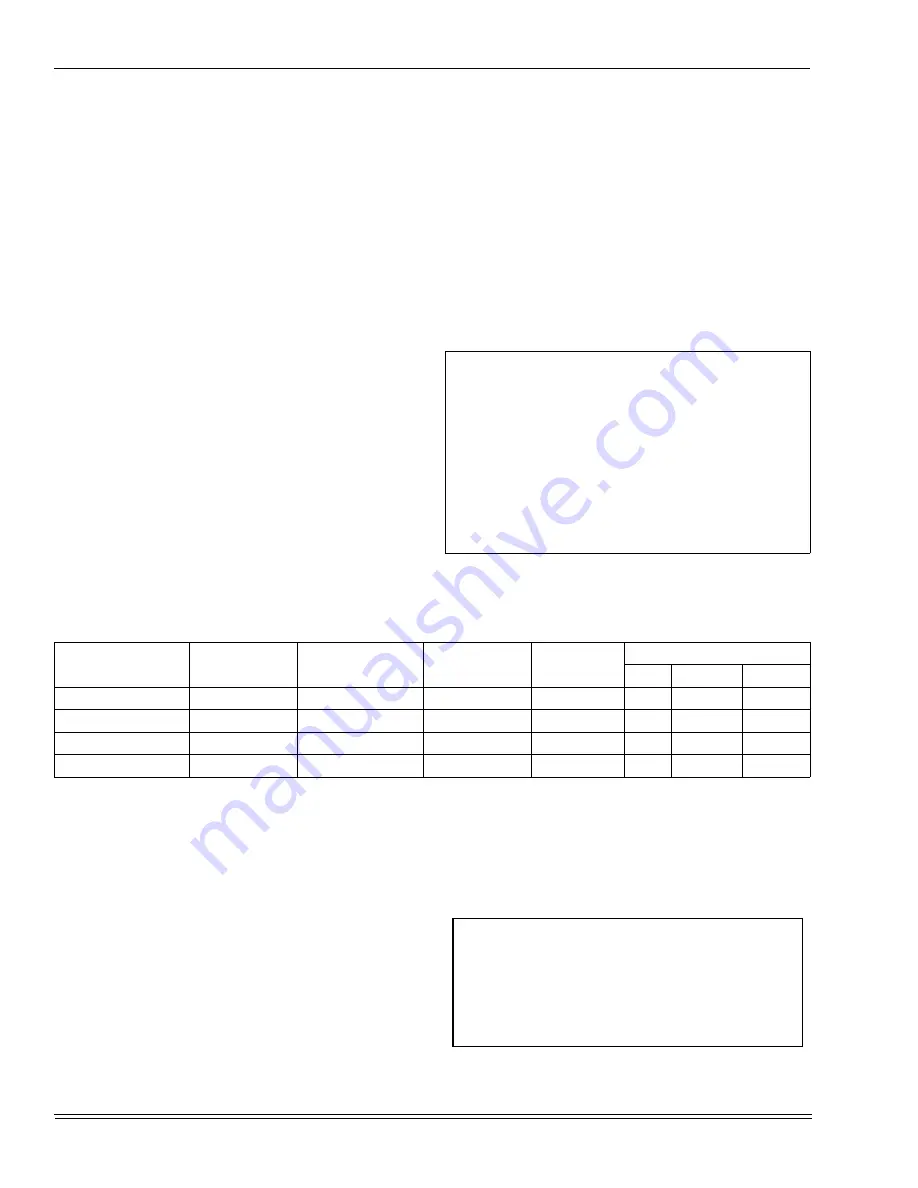

Table 7:

PSC MOTOR SELECTION

Model Number

Motor Part Num-

ber

Motor Horsepower

Capacitor Part

Number

Capacitor

Rating MF

Motor Speed Chart

Cool

Heat LO

Heat HI

80 / 64 / 1200 / “A”

024-31969-000

1/3

024-20045-000

7.5

BLK

BLU

BLK

100 / 80 / 1600 / “B”

024-27540-000

1/2

024-20046-000

10.0

BLK

RED

BLU

100 / 80 / 2000 / “C”

024-23238-001

1

024-20446-000

15.0

BLK

RED

BLU

120 / 96 / 2000 / “C”

024-23238-001

1

024-20446-000

15.0

BLK

BLU

BLK

IGNITION CONTROL (P/N 031-01909-000) Normal

flame sense current is approximately

2.4 microamps DC (

µ

a)

Low flame signal control lockout point is

0.15 microamps (DC (

µ

a)