035-20464-002 Rev. A (1004)

Unitary Products Group

7

This appliance is design certified for line contact when the furnace is

installed in the horizontal left or right position. The line contact is only

permissible between lines that are formed by the intersection of the top

and two sides of the furnace and the building joists, studs or framing.

This line may be in contact with combustible material.

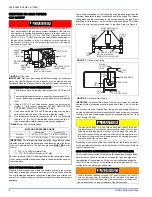

SUSPENDED FURNACE / CRAWL SPACE

INSTALLATION

The furnace can be hung from floor joists or installed on suitable blocks

or pad. Blocks or pad installations shall provide adequate height to

ensure the unit will not be subject to water damage. Units may also be

suspended from rafters or floor joists using rods, pipe angle supports or

straps. Angle supports should be placed at the supply air end and near

the blower deck. Do not support at return air end of unit. All four sus-

pension points must be level to ensure quite furnace operation. When

suspending the furnace use a secure platform constructed of plywood

or other building material secured to the floor joists. Refer to Figure 4

for typical crawl space installation.

SECTION III: FILTERS

FILTER INSTALLATION

All applications require the use of an external filter. Filter(s) and the filter

retainer are not provided on all models Some models are shipped with a

high velocity filter that must be field installed. A field-supplied external

filter and filter retainer hardware must be provided if the filter and the fil-

ter retainer are not shipped with the furnace. Refer to Table 4 for the

recommended filter size.

NOTE:

Air velocity through throwaway type filters may not exceed 300

feet per minute (91.4 m/min). All velocities over this require the

use of high velocity filters.

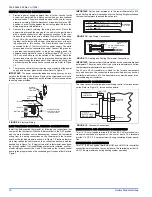

SIDE RETURN - EXTERNAL INSTALLATION

Locate and knock out the square corner locators. These indicate the

size of the cutout to be made in the furnace side panel. Refer to Figure 7.

Install the side filter rack following the instructions provided with that

accessory. If a filter(s) is provided at another location in the return air

system, the ductwork may be directly attached to the furnace side

panel. An accessory filter rack is available for mounting the filter exter-

nal to the cabinet.

IMPORTANT:

Some accessories such as electronic air cleaners and

pleated media may require a larger side opening. Follow the instruc-

tions supplied with that accessory for side opening requirements. Do

not cut the opening larger than the dimensions shown in Figure 1.

HORIZONTAL APPLICATION

Horizontal Filters

All filters and mounting provision must be field supplied. Filters(s) may

be located in the duct system external to the furnace or in a return filter

grille(s). Filters(s) may be located in the duct system using an external

duct filter box attached to the furnace plenum. Filters must be a mini-

mum distance of 18” (45.7 cm) from the furnace. Any branch duct (rect-

angular or round duct) attached to the plenum must attach to the

vertical plenum above the filter height. The use of straps and / or sup-

ports is required to support the weight of the external filter box.

When a furnace is installed in an attic or other insulated space,

keep all insulating materials at least 12 inches (30.5 cm) away from

furnace and burner combustion air openings.

FIGURE 4:

Typical Suspended Furnace / Crawl Space Installation

In any application where temperatures below freezing are possible,

see “BELOW FREEZING LOCATIONS”.

1” MAX. BETWEEN

ROD & FURNACE

SUPPORT

ROD

6” MIN BETWEEN

ROD & FURNACE

1” MAX. BETWEEN

ROD & FURNACE

ANGLE IRON

BRACKET

TABLE 5:

Filter Sizes

BTU/H (kW)

Input / Output

CFM

(m³/min)

Cabinet

Size

Side

(in)

Side

(cm)

Bottom

(in)

Bottom

(cm)

40/32 (11.71/9.38)

1200 (33.98)

A

16 x 25

40.6 x 63.5

14 x 25

35.6 x 63.5

60/48 (17.57/14.07)

1200 (33.98)

A

16 x 25

40.6 x 63.5

14 x 25

35.6 x 63.5

80/64 (23.42/18.76)

1200 (33.98)

A

16 x 25

40.6 x 63.5

14 x 25

35.6 x 63.5

80/64 (23.42/18.76)

1600 (45.31)

B

16 x 25

40.6 x 63.5

16 x 25

40.6 x 63.5

80/64 (23.42/18.76)

2200 (62.30)

C

(2)

16 x 25

(2) 40.6 x 63.5

20 x 25

50.8 x 63.5

100/80(29.28/23.42)

1200 (33.98)

B

16 x 25

40.6 x 63.5

16 x 25

40.6 x 63.5

100/80 (29.28/23.42)

1600 (45.31)

B

16 x 25

40.6 x 63.5

16 x 25

40.6 x 63.5

100/80 (29.28/23.42)

2000 (56.63)

C

(2) 16 x 25

(2) 40.6 x 63.5

20 x 25

50.8 x 63.5

115/92 (33.70/26.96)

1600 (45.31)

C

16 x 25

40.6 x 63.5

20 x 25

50.8 x 63.5

115/92 (33.70/26.96)

2000 (56.63)

C

(2)

16 x 25

(2) 40.6 x 63.5

20 x 25

50.8 x 63.5

130/104 (38.09/30.48)

2000 (56.63)

D

(2) 16 x 25

(2) 40.6 x 63.5

22 x 25

55.9 x 63.5

FIGURE 5:

Side Return Cutout Markings

FRONT OF

FURNACE

CORNER

MARKINGS

All installations must have a filter installed.