035-18877-001-B-0203

10

Unitary Products Group

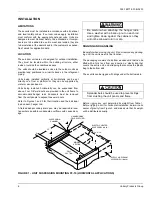

DRAIN CONNECTION

The drain line MUST be trapped because the coil is located

on the negative side of the supply air blower, and it must be

protected from freezing temperatures.

A 7/8” OD drain connections extends through right hand side

of the cabinet. Refer to Figure 9 for recommended drain pip-

ing.

The drain connection is located on the same side of the unit

as the refrigerant connections. The line should be insulated

where moisture drippage will be objectionable or cause dam-

age to the area.

The 3” dimension must equal or exceed the negative static

pressure developed by the supply air blower. If it does not the

condensate will not drain properly and may overflow the drain

pan. The trap must be at least 2-1/2” deep to maintain a

water seal under all operating conditions, especially during

blower start-up.

NOTE:

The unit may have to be raised off the floor to allow

enough height for the trap.

REFRIGERANT MAINS

Many service problems can be avoided by taking adequate

precautions to provide an internally clean and dry system and

by using procedures and materials that conform with estab-

lished standards.

Use hard drawn copper tubing where no appreciable amount

of bending around pipes or other obstructions is necessary.

Use long radius ells wherever possible with one exception -

small radius ells for any traps in a vapor riser. If soft copper is

used, care should be taken to avoid sharp bends which may

cause a restriction.

Fiber glass insulation and a sealing material such as perma-

gum should be packed around refrigerant lines where they

penetrate a wall to reduce vibration and to retain some flexi-

biltiy.

Support all refrigerant lines at minimum intervals with suitable

hangers, brackets or clamps.

Braze all copper to copper joints with Sil-Fos 5 or equivalent

brazing material.

DO NOT USE SOFT SOLDER

.

Never braze or solder the liquid and vapor lines together for

support purposes, they must be completely insulated, one

from the other.

Refer to the installation instructions (035-18549-001) for the

matching outdoor unit for piping limitations, line sizes and

other design considerations.

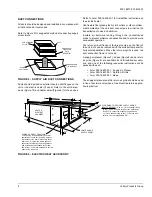

INSTALLING REFRIGERANT MAINS

The units are evacuated and dehydrated at the factory and

shipped with a holding charge of Refrigerant-22. The suction

and liquid connections are sealed with copper discs. Refer to

the appropriate condensing unit installation instructions for

charging data.

Before starting installation of the mains be sure the unit has

not developed a leak in transit by drilling a small hole in the

sealing discs. If pressure still exists, the circuit may be con-

sidered leak free. If pressure does not exist the coil should be

leak tested.

NOTE:

To

minimize the possibility of system failure

due to dirt and moisture, a filter-drier must be

installed in the liquid line as close to the evap-

orator as possible. Filter-driers are not sup-

plied with the evaporator blowers. They are

supplied with the matching condensing sec-

tions.

If solenoid valves are required, they must be purchased and

installed in the field. The temperature required to make or

break a brazed joint is sufficiently high to cause oxidation of

the copper unless an inert atmosphere is provided.

The liquid and suction connections must be piped outside the

unit. Refer to the unit drawing for locations and the dimen-

sions of these connections.

FIGURE 9 - RECOMMENDED DRAIN PIPING

5 "

2 - 1 / 2 "

P L A S T I C

E L L

S T E E L

S T U B

C O N N E C T I O N

H O S E C L A M P S

E V A P O R A T O R

C O I L

D R A I N P A N

D R A I N

P L U G

Dry nitrogen should flow through the system at

all times when heat is being applied and until

the joint has cooled.

Содержание FF-10

Страница 19: ...035 18877 001 B 0203 Unitary Products Group 19...