14

Matching the burner to the boiler

The burners described in this manual have been tested with combustion chambers that comply with EN676 regulation and whose

dimensions are described in the diagram . In case the burner must be coupled with boilers with a combustion chamber smaller in dia-

meter or shorter than those described in the diagram, please contact the supplier, to verify that a correct matching is possible, with

respect of the application involved. To correctly match the burner to the boiler verify the necessary input and the pressure in combu-

stion chamber are included in the burner performance curve; otherwise the choice of the burner must be revised consulting the burner

manufacturer. To choose the blast tube lenght follow the instructions of the boiler manufacturer. In absence of these consider the fol-

lowing:

Cast-iron boilers, three pass flue boilers (with the first pass in the rear part): the blast tube must protrude no more than 100 mm into

the combustion chamber.

Pressurised boilers with flame reversal: in this case the blast tube must penetrate at least 50 - 100 mm into combustion chamber in

respect to the tube bundle plate.

The length of the blast tubes does not always allow this requirement to be met, and thus it may be necessary to use a suitably-sized

spacer to move the burner backwards or to design a blast tube tha suites the utilisation (please, contact the manifacturer).

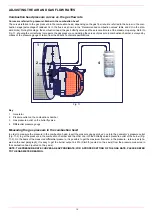

Installing the gas train

The following diagram shows the gas train components which are included in the delivery and those which must be fitted by the custo-

mer. The diagram complies with regulations in force.

Key

1 Burner

2 Butterfly valve

3 Gas proving system (option)

4 Maximum gas pressure switch (option*)

5 Minimum gas pressure switch

7 Bellows unit

8 Manual cutoff valve

9 MB-DLE valve group

*Note: the maximum gas pressure switch can be mounted either upstream or downstream the gas valve but upstream the butterfly gas

valve (see item no.4 in the scheme above).

NOTE:

the bellow joint, the manual valve and the gaskets are not part of the standard supply.

To mount the gas train, proceed as follows:

1)

in case of threaded joints: use proper seals according to the gas used;

Fig. 2

Key

a) Heat output in kW

b) Length of the flame tube in meters

c) Flame tube firing intensity in MW/m

3

d) Combustion chamber diameter (m)

Fig. 2 - Firing intensity, diameter and lenght of the test flame tube as a function of the

heat input in kW.

ATTENTION:

BEFORE EXECUTING THE CONNECTIONS TO THE GAS PIPE NETWORK, BE SURE THAT THE

MANUAL CUTOFF VALVES ARE CLOSED. READ CAREFULLY THE “WARNINGS” CHAPTER AT THE BEGINNING

OF THIS MANUAL.

Gas train with valves group MB-DLE (2 gas pressure governor) + VPS504 gas proving system

1

2

3

4

5

7

8

9

4

MANUFACTURER

INSTALLER