39

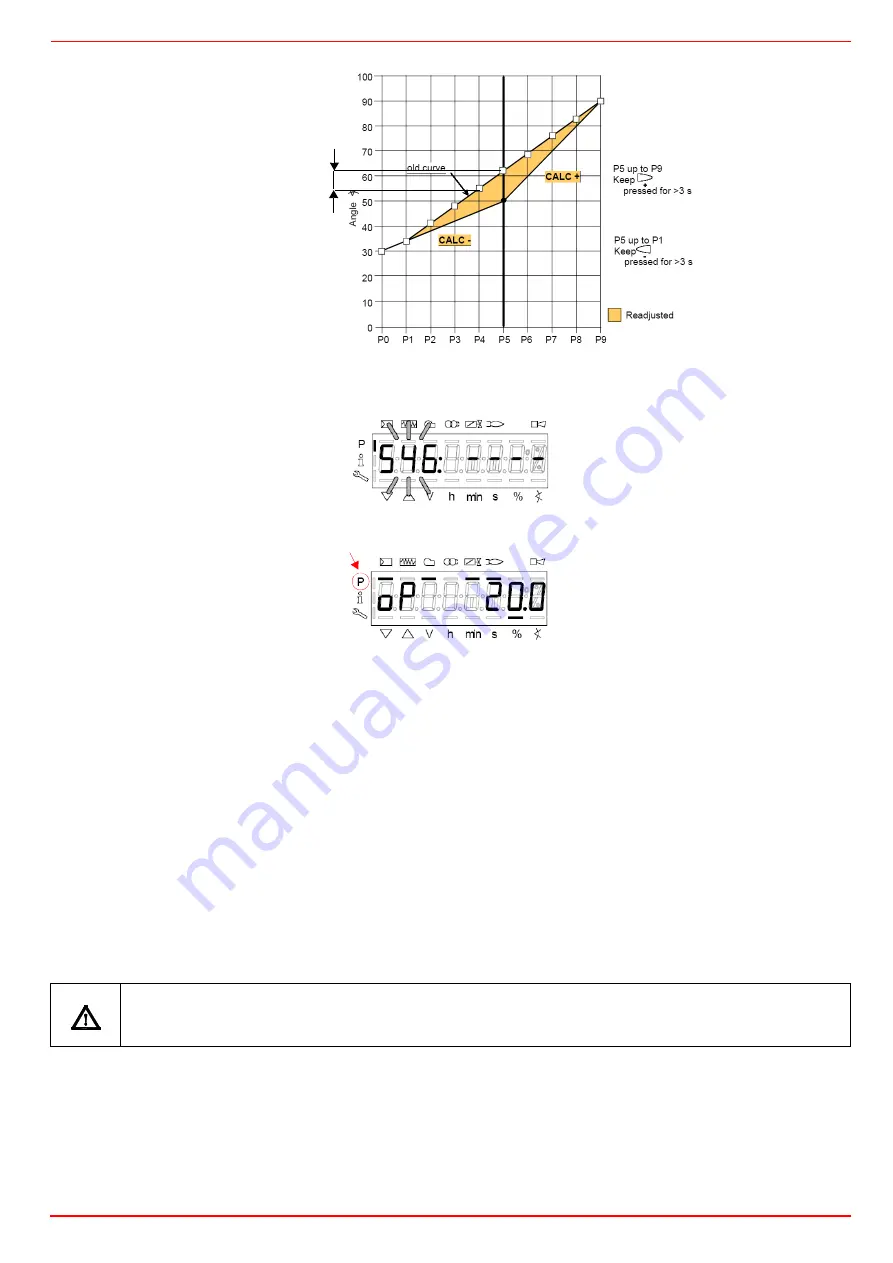

P5, keep pressing “-” unitl “Calc” is displayed. The curve will be processed again downwards point P1.

12 press “-” to go through the lower points and check the combustion values, if necessary change the points as described above.

13 By pressing ESC, at the end of the points adjusments, the parameter “

546”

(setting the maximum load) will be displayed; press

ENTER (InFo), then “+” until 100%, then press ENTER (InFo) again, ESC and then “+”.

14 The parameter “

545”

(setting the minimum load) is displayed: press ENTER (InFo), then “+” until 20%. Press ENTER, then press

ESC for three times. The message “oP” will be displayed as well as the load percentage at the burner is working on.

he hyphen related to the symbol “P” (highlited in the picture) will be off to show that the unit exited the programmig mode. The burner

will then work automatically, following the curve set.

.

Note1:

if the curvepoints settings is quit before end (by pressing ESC or for a faulty shutdown), the message “OFF UPr” (Start preven-

tion) will be diplayed until all the curvepoints will be set.

Note2:

if the gas flow rate at high flame point (maximum load) is changed by means of the pressure stabiliser, all the curvepoints must

be checked by going through the curve downwards and resetting them if necessary.

Note3:

if the point does not flash, it means thet the actuators have not reached the set position yet.

Note4:

if an error occurs causing a safety shutdwon during the processing of the curve, the processing itself will be interrupted.

Cold setting

The ”cold setting“ (without flame) can be performed only when all the curve points values are known (for instance, in case of replace-

ment).

When the burner is off, if you modify one curve set point, when the burner restarts the AZL2x shows OFF UPr

(OFF UPr0 or OFF UPr1 for LMV26). The LMV.. then, requires a new "warm" startup (see procedure paragraph

"Warm Setting”) by checking again all points of curve from P0 to P9.

deviation between two

following points: 25°max.

Fuel

An

golo

Содержание KPBY70

Страница 33: ...PART III OPERATION 33 FLUIDICS 12AG 90Kg h...

Страница 53: ......

Страница 54: ......

Страница 55: ......

Страница 57: ...Service manual AZL2x LMV2x 3x Burner Management System M12916CD Rev 3 4 03 2023...

Страница 64: ...8 Parameters level heating engineer...

Страница 106: ...50 ERROR CODE TABLE...

Страница 107: ...51...

Страница 108: ...52...

Страница 109: ...53...

Страница 110: ...54...

Страница 111: ...55...

Страница 112: ...56...

Страница 113: ...57...

Страница 114: ...58...

Страница 115: ...59...

Страница 116: ...60...

Страница 117: ...61...

Страница 118: ...62...

Страница 119: ...63...

Страница 120: ...64...

Страница 122: ...66 Wiring variants for LMV27 2 Fuel meter input 1 Supply fuel meter ConnectorX75 ConnectorX5 02 ConnectionsPmax...

Страница 125: ......

Страница 126: ......

Страница 127: ......

Страница 142: ......

Страница 151: ......

Страница 152: ......

Страница 153: ...RWF50 2x RWF50 3x User manual M12922CB Rel 1 0 07 2012...

Страница 168: ...16 Note Specifications and data subject to change Errors and omissions excepted...

Страница 169: ...KM3 Modulator USER MANUAL M12927CA Rel 1 0 10 2020...

Страница 170: ...M12927CA MOUNTING 2...