PART III: MAINTENANCE

50

ROUTINE MAINTENANCE

Check and clean the gas filter cartridge, if necessary replace it (see next paragraghs);

Check and clean the fuel filter cartdrige, replace if necessary.

Check and clean the filter inside the light oil pump: filter must be thoroughly cleaned at least once in a season to ensure correct

working of the fuel unit. To remove the filter, unscrew the four screws on the cover. When reassemble, make sure that the filter is

mounted with the feet toward the pump body. If the gasket between cover and pump housing should be damaged, it must be repla-

ced. An external filter should always be installed in the suction line upstream of the fuel unit.

Check the fuel hoses for possible leaks.

Remove, check and clean the combustion head (see page 51);

Check ignition electrodes, clean, adjust and, if necessary, replace them (see page 57);

Check and carefully clean the

UV

detector, replace it if necessary; if in doubt, check the detection current, once the burner starts up

(see on page 53).

Remove and clean the fuel nozzle

(Important:

cleaning must be performed using solvent, not metal tools!

).

At the end of

maintenance operations after the burner reassembly, light the flame and check its shape, replacing the nozzle whenever a questio-

nable flame shape appears. Whenever the burner is used intensely, we recommend preventively replacing the nozzle at the start of

each heating season.

Clean and grease sliding and rotating parts.

Gas filter maintenance

1 Close the bowl valve before the self cleaning filter

2 Switch off any electrical equipment on board on the filter (example motorization or heaters)

3 Disconnect the outlet pipe from the cover of the self cleaning filter

4 Remove the cover with all the filter pack, leaving only the bowl on the line

5 Clean any residue on the bottom of the bowl and clean the seat of the O-ring seal

6 Insert the filter pack again making sure to respect the correct inlet/outlet direction or any references on the cover and tray

7 Replace the filter by following the reverse order operations

8 Make sure there is no leakage and give the power to any electrical equipmente on the filter

ATTENTION:

when servicing, if it was necessary to disassemble the gas train parts, remember to execute the gas proving

test, once the gas train is reassembled, according to the procedure imposed by the law in force.

WARNING: Before opening the filter, close the manual cutoff valve downstream the filter and bleed the gas; check

that inside the filter there is no pressurised gas.

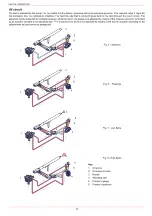

Thecnical procedure of self cleaning filters substitution (valid for all models)

WARNING! Drain the system by unscrewing the drain screw on the bottom of the self cleaning filter

WARNING! Replace the O-ring seal between the bowl and cover

C

B

A

To clean or remove the filter, proceed as follows:

1 remove the cap unscrewing the fixing screws (A);

2 remove the filtering cartridge (B), clean it using water and soap, blow it

with compressed air(or replace it, if necessary)

3 replace the cartridge in its proper position taking care to place it

inbetween the guides as not to hamper the cap replacement;

4 be sure to replace the “O” ring into its place (C) and replace the cover

fastening by the proper screws (A).

Содержание HTLX92R

Страница 57: ...Siemens LMV5x Service Manual M12920CC rev 2 1 08 2017...

Страница 64: ...8...

Страница 65: ...9 1 4 1 Servomotor wiring example 1 4 2 Bus cable wiring on LMV5x and AZL doors 1 4 3 EARTH connection example...

Страница 68: ...12 2 2 LMV5x program structure...

Страница 95: ...39...

Страница 102: ......

Страница 103: ......

Страница 104: ...Note Specifications and data subject to change Errors and omissions excepted...

Страница 106: ...Annex1 Example for motor cable...

Страница 107: ......

Страница 108: ...Annex 2 Example for sensor cable...

Страница 109: ......

Страница 110: ......

Страница 114: ......