PART II: INSTALLATION

16

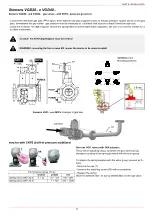

Fitting the burner to the boiler

To install the burner into the boiler, proceed as follows:

1

make a hole on the closing door of the combustion chamber as described on paragraph “Overall dimensions”)

2

place the burner to the boiler: lift it up and handle it according to the procedure described on paragraph “Handling the burner”;

3

place the 4 stud bolts (5) on boiler’s door, according to the burner drilling template described on paragraph “Overall dimensions”;

4

fasten the 4 stud bolts;

5

place the gasket on the burner flange;

6

install the burner into the boiler;

7

fix the burner to the stud bolts, by means of the fixing nuts, according to the next picture.

8

After fitting the burner to the boiler, ensure that the gap between the blast tube and the refractory lining is sealed with appropriate

insulating material (ceramic fibre cord or refractory cement).

Matching the burner to the boiler

(

low NOx burners)

The burners described in this manual have been tested with combustion chambers that comply with EN676 regulation and whose

dimensions are described in the diagram. In case the burner must be coupled with boilers with a combustion chamber smaller in diame-

ter or shorter than those described in the diagram, please contact the supplier, to verify that a correct matching is possible, with respect

of the application involved. To correctly match the burner to the boiler verify the type of the blast tube. Verify the necessary input and

the pressure in combustion chamber are included in the burner performance curve; otherwise the choice of the burner must be revised

consulting the burner manufacturer. To choose the blast tube lenght consider the following rule, even if it differs from the instructions of

the boiler manufacturer:

Fan installation

Pay attention when designing the air duct: dimensioning must be performed according to the flow rate, the temperature, the distance

between the fan and the burner and according to the fan features as well.

ATTENTION!

The bellows unit provided is made of canvas and is provided with blocking spacers to avoid breaking it during

installation:

first

place the bellows unit between flanges,

then

remove the spacers. Canvas has to be stretched after the instal-

lation, but not stressed.

4

1

2

3 4

5

6

7

6

Keys

1

Burner

2

Fixing nut

3

Washer

4

Sealing gasket

5

Stud bolt

7

Blast tube

Cast-iron boilers, three pass flue boilers (with the first pass

in the rear part): the blast tube must protrude about

150÷200 mm into the combustion chamber (Fig.

A

).The

length of the blast tubes does not always allow this

requirement to be met, and thus it may be necessary to use

a suitably-sized spacer to move the burner backwards

(Fig.

B

).

5° MAX

150÷200 mm

WARNING! Carefully seal the free space between blast tube and

the refractory lining with ceramic fibre rope or other suitable

means.

ceramic fibre

refactory wall

B

A

Содержание HTLX92R

Страница 57: ...Siemens LMV5x Service Manual M12920CC rev 2 1 08 2017...

Страница 64: ...8...

Страница 65: ...9 1 4 1 Servomotor wiring example 1 4 2 Bus cable wiring on LMV5x and AZL doors 1 4 3 EARTH connection example...

Страница 68: ...12 2 2 LMV5x program structure...

Страница 95: ...39...

Страница 102: ......

Страница 103: ......

Страница 104: ...Note Specifications and data subject to change Errors and omissions excepted...

Страница 106: ...Annex1 Example for motor cable...

Страница 107: ......

Страница 108: ...Annex 2 Example for sensor cable...

Страница 109: ......

Страница 110: ......

Страница 114: ......