7

Figure 3 Figure 4 Figure 5

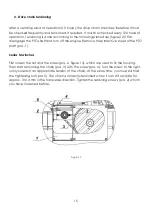

28. Do not use the winch for unintended purposes (lifting loads, etc.).(Figure 5)

29. Tractor driver and assistant must continuously communicate during their work.

30. The winch operator must continuosly observe the load during the tow. If this is not

possible due to the configuration of the terrain, the assistant should help.

31. The tractor to which the winch is connected to must have a minimum tyre profile

which still meets the traffic regulations. Otherwise the wheels must be fitted with snow

chains. Chains are also obligatory when working in snow and ice.

32. When disconnecting the winch, you first need to choose an appropriate hard and flat

surface. Fix the winch by means of support legs. Lean the drive shaft on the prepared

holder.

33. In the area of the three point linkage there is a danger of injuries due to compression

or crushing.

34. The winch can be operated only from a safe place from which the load, wire rope,

rope hook or the winch itself do not pose a threat to the operator. A safe place can

also be the tractor seat if the winch has a safety net of sufficient size. When operating

the winch outside the tractor seat the operator must be provided with an appropriate

protection, e.g. the tractor itself, secure location at a sufficient distance from the

vehicle, e.g. behind a tree. Logs can be monitored from the side next to the

connection and shorter timber can be monitored diagonally behind the load. (See

Figure 6).