UNIFLEX-Hydraulik – 18 – www.uniflex.de

Chapter 6

Maintenance

Maintenance, Service, Repair

All maintenance and repair works may only be performed by authorized and trained personnel.

•

Stick to the specified maintenance and inspection periods.

•

Inform the operating personnel prior to conducting all special works on the machine.

•

Identify a supervisor prior to this work.

•

For all works that modify the operation, the settings according to products, general modification of the setting of

the machine and its security relevant devices adhere to the correct activation / deactivation procedures

mentioned in this document. If necessary secure the area.

•

If the machine is turned off completely for maintenance or repair works, ensure against unintended switching

on: Set up a warning sign.

•

Clean the machine and all (screwed) connections off oil, fuel or cleaning agents! Do not use any aggressive

cleaning agents! Use fibreless cleaning cloths!

•

After the cleaning check all fuel-, motor oil- and hydraulic oil connections for leakage, loose connections,

abrasion and other damages. Remove these faults immediately!

•

If a disassembling of protecting devices becomes necessary during the general assembling, maintenance- or

repair works of the machine, a remounting after finishing the works has to follow immediately.

•

Always refasten the screws that were loosened during maintenance and repair.

•

If the disassembling of any safety installations becomes necessary during maintenance, service or repair it

needs to be replaced and checked directly after finishing the works.

•

Make sure to discard all operating and auxiliary materials safely and environmentally friendly.

•

Only conduct welding, firing or grinding on the machine if it is explicitly allowed, as there may be the danger of

fire or explosion!

•

Prior to any welding, firing or grinding clean the machine and the surroundings of dust and flammable

substances and provide adequate ventilation (Danger of explosion)!

Attention:

Do not remove safety installations!

Attention:

Check the functioning of the emergency stop button regularly!

Attention:

The machine needs to be switched off on the main switch during all maintenance works!

Содержание EM 1

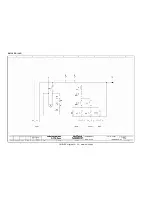

Страница 32: ...UNIFLEX Hydraulik 32 www uniflex de EM 2 400 V 50 60 Hz 3...

Страница 33: ...UNIFLEX Hydraulik 33 www uniflex de EM 3 4 DC 24V...

Страница 34: ...UNIFLEX Hydraulik 34 www uniflex de EM 3 4 DC 12VDC 24VDC...

Страница 35: ...UNIFLEX Hydraulik 35 www uniflex de EM 3 2 Ecoline...

Страница 36: ...UNIFLEX Hydraulik 36 www uniflex de EM 3 3 220 230 V 60 Hz 3...

Страница 37: ...UNIFLEX Hydraulik 37 www uniflex de EM 3 3 440 460 V 60 Hz 3 380 415 V 50 Hz 3...

Страница 40: ...UNIFLEX Hydraulik 40 www uniflex de Note...