- 15 -

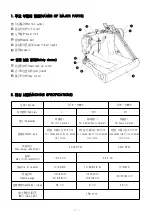

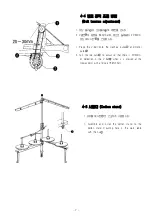

8-2 윤활유 의 교환(3개월마다) (Changing the lubricating oil(every 3 m onths))

☞

윤활유의 교환은 3개월에 1번 정도의 비율로 교환하

여 주십시오.

1. 고정나사①(11개)를 풀고 이송완카바②를 떼어냅니다.

2. 기름통(소)③으로 속의 윤활유를 빼냅니다.

3. 오일 게이지의 기선 중앙까지 급유합니다.(p7 참조)

4. 이송완카바②를 고정나사①(11개)로 조절합니다.

☞

The lubricating oil should be changed at least

once every three months.

1. Remove the set screws①(11pcs), and then open

the forward feed arm cover②

2. Draw up all of the lubricating oil inside the machine

into the oil bottle③.

3. Fill the machine with oil until the oil level reaches the

point in between the reference lines on the oil

gauge. (Refer to page 7)

4. Close the forward feed arm cover② and secure it

with the set screws①(11pcs).

9. 표준 조정 (STA NDARD ADJUSTMENTS)

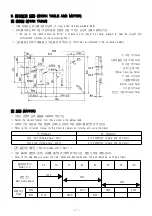

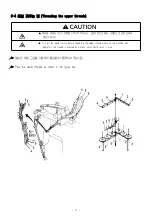

9-1 침봉 높이 조정

☞

바늘①의 높이를 조정합니다. 이 때, 각각의 바늘①이

중심에 오도록 조정합니다.

1. 고정나사⑦를 풀고, 노루발⑧을 떼어 냅니다.

2. 풀리를 돌려서 침봉을 최하점까지 내립니다.

3. 침포③하면과 침판②상면의 높이를 박물 11.3mm,

중후물 10.1mm로 합니다. 침봉포고정나사를 풀고 조정

합니다.

※

침포를 위쪽으로 오도록 설정하면, 침포 최상 위치

일 때, 바늘 끝과 침판 상면의 높이는 박물 8.5mm․

중후물 10.3mm로 됩니다.

4. 고정나사⑤(3개)를 풀고 침판②을 풉니다.

5. 풀리를 돌려서 바늘①과 바늘 받침대④가 일치할

때는 좌우의 바늘①과 바늘 받침대④의 유격이

0 이 되도록 침포③의 기울기를 조정합니다.

침판②을 고정나사⑤(3개)로 조립하고, 바늘①이

바늘구멍⑥의 중심에 있을 때를 확인하고 나서

침봉포 고정나사를 체결합니다.

6. 노루발⑧을 고정 나사⑦로 조립합니다.

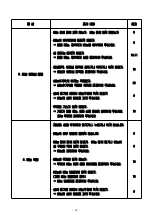

Содержание DT6-H892?3

Страница 2: ......

Страница 4: ...5 off A S 31 2 40 25 OFF A S A S...

Страница 32: ...22 10 1 13 19 2 9 16 16 20 16 3 13 19 4 19 13...

Страница 34: ...24 5 9 9 10 11 13 20 9 16 6 9 9 16 18 9...