13

Metal Type

Thickness of

Material Being

Welded

Wire Type/ Size

Tweco

#2 Tip Size Shield Gas

Gas

Flow

Rate

Polarity/

Connection to

Tactical Welder

Wire Speed

Control

Setting

Steel

24 – 18 GA

Solid Steel .023”

.023”

75% Argon/ 25% CO2 15-30

DCEP

Stitch

18 GA – 3/16”

Solid Steel .030”

.030”

75% Argon/ 25% CO2 15-30

DCEP

Stitch - 1

1/8” Plus

Solid Steel .035”

.035”

75% Argon/ 25% CO2 15-30

DCEP

Stitch – 2

1/4” Plus

Solid Steel .040”

.040”

75% Argon/ 25% CO2 15-30

DCEP

1 – 4

22 – 14 GA

Flux-Core Steel .030”

.030”

None

None

DCEN

Stitch – 1

1/8” – 3/8”

Flux-Core Steel .035”

.035”

None

None

DCEN

Stitch – 3

1/4” – 1/2” Plus Flux-Core Steel .040”

.040”

None

None

DCEN

3-6

Aluminum

.060”- 1/8”

Aluminum .023”

.030”

100% Argon

10-20

DCEP

1 – 2

1/8” – 1/2”

Aluminum .035”

.040”

100% Argon

15-30

DCEP

2 – 6

1/2” Plus

Aluminum .040”

.045”

100% Argon

20-50

DCEP

4 – 9

Stainless Steel

.080”- 1/8”

Solid Stainless .030”

.030”

Tri-Mix*

20-40

DCEP

Stitch – 1

1/8” Plus

Solid Stainless .035”

.035”

Tri-Mix*

20-40

DCEP

1 – 6

1/8” Plus

Flux-Core Stainless .035” .035”

None

None

DCEN

1 – 6

Application Table

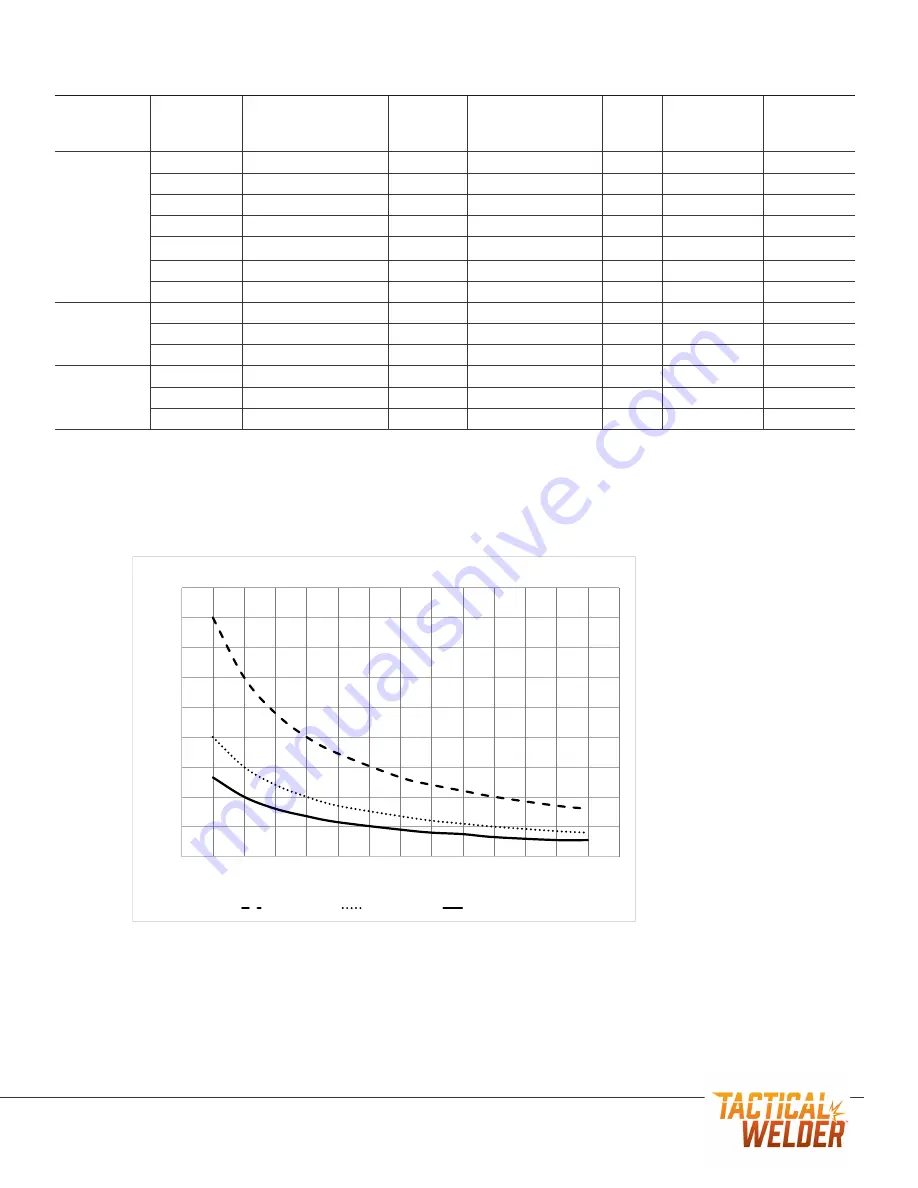

Weld Time per Charge

*Tri-Mix: The specific mix of gases and their respective proportions will be determined by 1. The alloy and thickness of the

stainless steel being welded, and 2. The alloy and thickness of the stainless welding feed wire being used. Please consult

your welding gas distributor or an appropriate reference manual to determine the proper mixture for your application.

General Guidelines

1.

Stitch Mode Welding: When welding metal thinner than 1/8” with batteries as a power source, it is often necessary to use a stitch mode welding

procedure to avoid melting the metal being welded. Start by lowering the wire feed speed control to its lowest setting where the wire just begins to

feed. When you begin welding, a small bead will form and then the wire will melt back just enough to break the arc. The process will weld a series of

small beads with short breaks of time between them. This prevents heat from building up and melting through, known as globular transfer.

2.

Aluminum Welding: We recommend using a contact tip which is .005” bigger than the aluminum feed wire itself and pulling the nozzle about 3/8”

farther out to reduce burn-back.

0

20

40

60

80

100

120

140

160

180

40

60

80

100

120

140

160

180

200

220

240

260

280

300

320

W

el

d

Ti

m

e i

n

Mi

nu

tes

Weld Current (Amps)

Weld Times Per Charge

10% Duty Cycle

20% Duty Cycle

33% Duty Cycle

Содержание Tactical Welder 4800

Страница 9: ...9...

Страница 15: ...15 Tactical Welder Circuit Diagram...