18

MT GL/GLS/UL

polycarbonate.

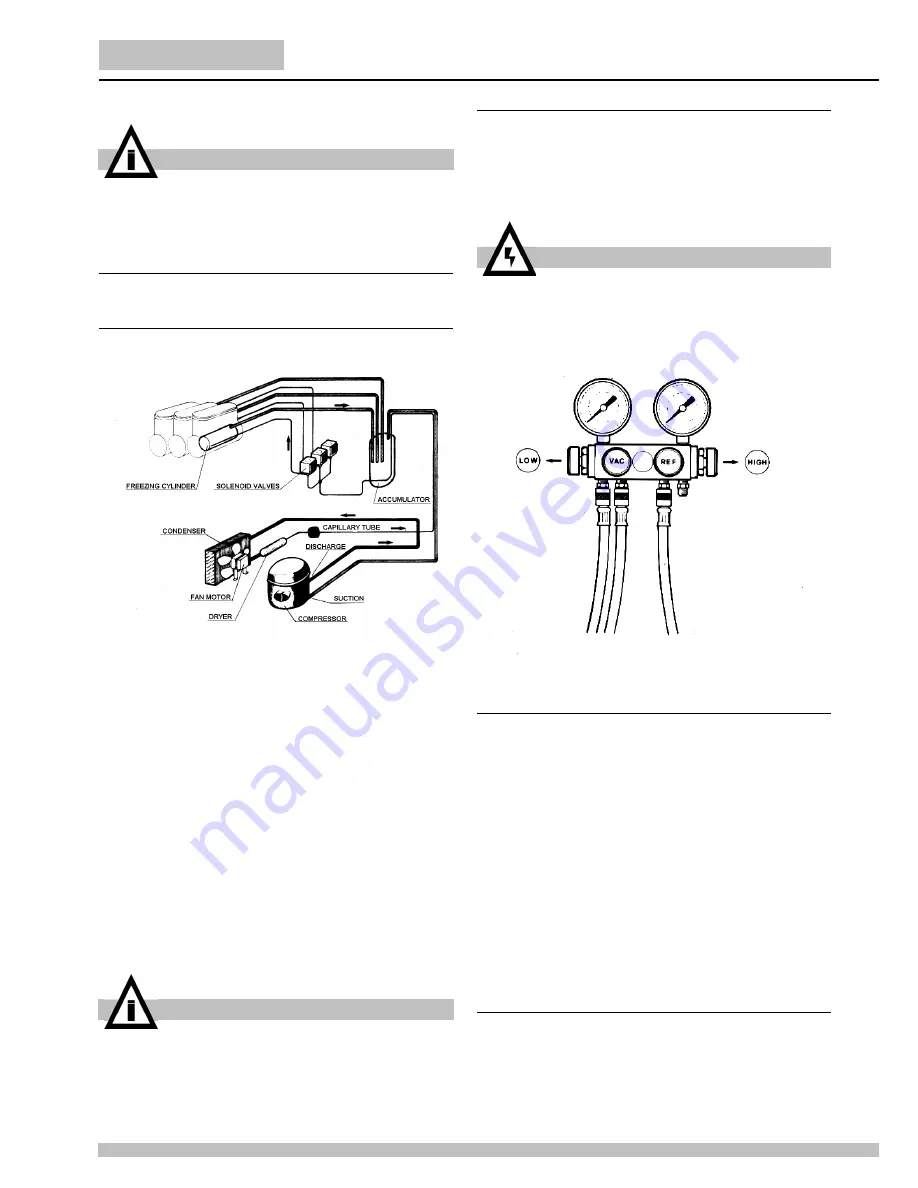

13. 2 REFRIGERANT CIRCUIT SERVICE

13. 2. 1 CHECKING FOR REFRIGERANT LEAKS

The following procedure is the recommended approach to

systematically inspect the entire system for refrigerant leaks.

figure 13

NOTE

: when using refrigerant leak detector, follow along the

bottom side of the copper tubing. The refrigerant gas is heavier

than air. Where copper tubing is protected by an insulating

jacket, check for leaks at both ends of each jacket section.

Referring to figure 4, perform the following steps:

1

Start inspection at the high pressure line of the compressor.

Check around the soldered connection.

2

Follow the copper tubing to the condenser and check

around the soldered connections at the top and bottom of the

condenser.

3

Check also along the copper curves on both sides of

condenser.

4

Follow the copper tubing to the evaporators, checking

around the soldered connections of dryer and solenoid valves.

5

Remove mixer motors and check the inlet (capillary) and

outlet (suction) tubing.

6

Check the copper tubing all the way back to the

compressor.

7

Check around the low side connections of the compressor

suction and process tubes.

If a leak has been detected, seal it and make a new refrigerant

charge as per instructions in the following paragraphs.

13. 2. 2 DISCHARGING

1

Remove the dispenser panels.

2

Remove the screw cap from the compressor process tube.

3

Connect the process tube to the LOW part of the gauge set.

4

Connect the VAC port of the gauge set to an adequate

approved gas recovery system.

5

Open the LOW and VAC valves and recover the refrigerant.

6

Once the recovery operation is completed, close the LOW

and VAC valves and disconnect the recovery system.

figure 14

13. 2. 3 EVACUATING

Always install a brand new liquid line filter dryer before

evacuating.

1

Connect the REF port of the gauge set to the charging unit.

2

Connect the VAC port of the gauge set to the vacuum pump

and open the VAC valve.

3

Open the line valve of the charging unit and, for a while,

also the REF valve so as to purge air from the REF hose.

4

In multiple bowl models, disconnect the dispenser internal

wiring from all solenoid valves and energize them directly

through an external power source. This way the valves are

opened and the entire system is ready to be evacuated.

5

Open the LOW valve of the gauge set and turn on the

vacuum pump for a minimum of half an hour.

6

While the pump is running, close the VAC valve once a

vacuum has been established.

7

Turn off the vacuum pump.

8

Disconnect the solenoid valves from the external power

source and restore the internal wiring.

13. 2. 4 CHARGING

In the figure 4, the gauge set is shown with four ports (and four

valves) which is the easiest option to be found in the market

since it allows the charging through both low and high side of the

system. Our refrigeration systems are manufactured so as to be

chargeable through the compressor process tube only (low

side): thus, the HI port is never mentioned nor used in the

IMPORTANT

The electric diagram of the dispenser is located in the

inner part of the dispensing side panel.

IMPORTANT

To check for a leak in the low side of the system, it is

advisable to have the evaporators at least at ambient

temperature.

ATTENTION

The refrigerant gas could be highly acid and toxic.

Содержание MT GL

Страница 1: ...MANUALE DI SERVIZIO SERVICE MANUAL MT GL GLS UL...

Страница 2: ...2 MT GL GLS UL...

Страница 12: ...12 MT GL GLS UL 7 SCHEMI ELETTRICI PER MACCHINE PRODOTTE FINO A MARZO 2002 7 1 VERSIONE GLS 7 2 VERSIONE GL UL...

Страница 13: ...13 8 SCHEMI ELETTRICI PER MACCHINE PRODOTTE DOPO APRILE 2002 8 1 VERSIONE GLS 8 2 VERSIONE GL UL...

Страница 23: ...23 16 WIRING DIAGRAMS MACHINES MANUFACTURED AFTER JANUARY 2002 16 1 GLS VERSION 16 2 GL UL...