II.

There are two types of powder actuated tools:

1.

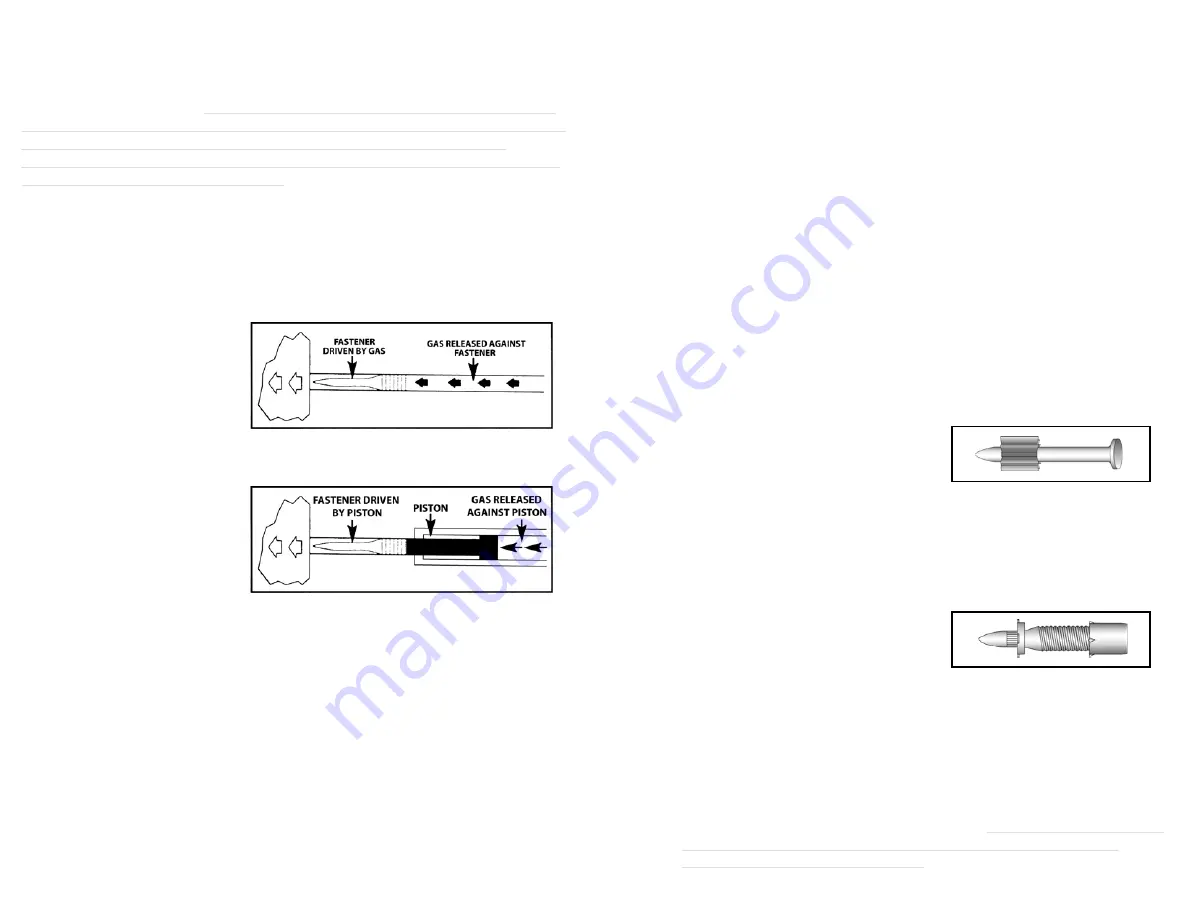

Direct acting tools operate by the action of the expanding gas of

the cartridge acting directly on the fastener to drive it into the work

surface.

2.

Indirect acting tools have a captive piston which is driven by the

expanding cartridge gas. The piston then drives the fastener into the

work surface.

There are three velocity classes of powder actuated tools. The velocity

class of the tool is determined by a ballistic test utilizing the lightest fastener

and the strongest cartridge which is designated for use with the tool by the

manufacturer.

A.

High velocity class - A tool produces an average test velocity over

150 meters (492 feet) per second.

B.

Medium velocity class - A tool which produces an average test

velocity greater than 100 meters (328 feet) per second, but not

exceeding 150 meters (492 feet) per second.

C.

Low velocity class - A tool which produces an average test velocity

which does not exceed 100 meters (328 feet) per second.

UCAN Fastening Products LV Powder Actuated Tools are indirect-acting

tools which conform to the requirements for low velocity class tools.

I.

Powder actuated fastening systems provide a means to make direct,

forced entry fastenings into a variety of base materials for construction and

maintenance applications. The system consists of a tool; a fastener; and a

power load or cartridge. The qualified operator is the key to safe, efficient

use of the system and therefore must be trained and licensed according to

UCAN Fastening Products standards and procedures. The qualified

operator must also follow any local regulations that apply to the use of the

powder actuated fastening systems.

POWDER ACTUATED TOOLS

POWDER ACTUATED FASTENING SYSTEMS

III. SHIELDS AND SPECIAL FIXTURES

Use of a shield/stabilizer is recommended when fastening directly into base

material (e.g. when installing threaded studs).

IV. FASTENERS

Fasteners used in powder actuated fastening systems are manufactured

from special steels and heat treated by a special process which insures that

they are hard enough to drive into concrete and steel yet are not brittle.

The fact that the fasteners are ductile (not brittle) permits them to be driven

into concrete or steel without shattering or breaking during normal appli-

cations. Powder actuated fasteners normally have a plastic or metal

washer or eyelet around the shank. These devices perform two functions:

1.

Assist in holding the fastener in the tool prior to driving it into the work

surface.

2.

To provide alignment and guidance for the fastener during the

driving process.

The most common fastener used with powder actuated tools is the drive

pin. The drive pin makes a permanent fastening (ie., the material that you

are fastening to the base material cannot normally be removed without

damage to the material or the base material.)

The threaded stud fastener is comprised of a shank portion which is driven

into the base material and a threaded portion onto which a nut is inserted.

This type of fastener is used for semi-permanent fastening where the

material to be fastened to the base material has a pre-drilled hole or slot

and is inserted over the threaded stud (after it is driven), then fastened

down with the nut and washer combination.

There are also other specialty fasteners made for powder actuated

applications such as eye pins; conduit clips; ceiling clips; etc., designed to

make certain trade applications easier. In addition, large diameter metal

washers are sometimes assembled to drive pins and provide more bearing

surface to accommodate fastening of insulations, sill plates (where required

by local codes), etc.

NOTE:

Remember that P.A.T. fasteners are made of special steel and heat

treated especially for these applications. Under no circumstances

should fasteners other than those recommended by the tool

manufacturer be used in the tool.