-!).4%.!.#% !.$ 34/2!'%

1.

Clean and lubricate the tool as recommended in the Instruction

Manual.

02/0%2 -!).4%.!.#% !.$ 34/2!'% /& 0/7$%2 !#45!4%$

4//,3 )3 .%#%33!29 4/ %.352% #/.3)34%.4 42/5",%&2%%

/0%2!4)/. !.$ (%,0 02%6%.4 ).*529

2.

Check tools prior to each day's use to ensure they are in proper

working order.

5.

Powder actuated tools and cartridges shall be locked in a container

and stored in a safe place when not in use. Only authorized

personnel, trained to use the tool, should have access.

4.

Any tool found not in working order should be immediately removed

from service, tagged as "defective" and used again only after being

repaired by a qualified individual. Use only repair/replacement

parts recommended by the tool manufacturer.

3.

Replace worn or damaged parts as required.

/0%2!4)/.

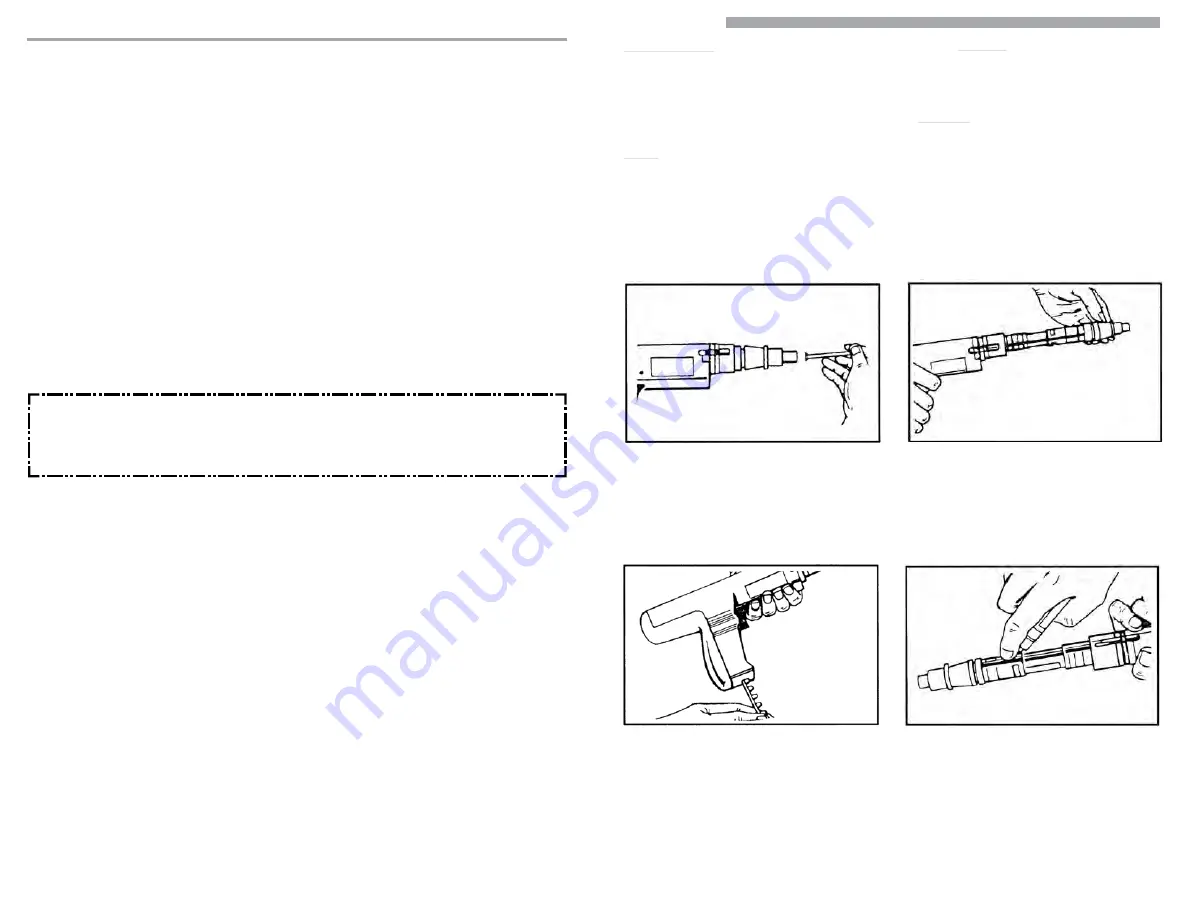

IMPORTANT: To make successive fastenings,always insert the fastener

before advancing magazine as in illustrations 1 & 2. Overdriving due to

using too strong a cartridge, too short a fastener, or too little resistance in

the base material can result in deformation of the shear clip. If this should

occur, the shear clip must be replaced. Always completely remove

the magazine before disassembly or cleaning of the tool. The magazine

must always be removed from the top of the tool - never from the

handgrip. Your LV360 must always be unloaded before:

- changing any parts (piston, piston sleeve, etc.)

- taking a work break - servicing and cleaning

- storing at the end of the work day.

After removing each magazine, the breech must be inspected for foreign

particles.

1.

With the point out, insert fastener into the guide until it is held in place

by the plastic washer.

2.

In one movement, pull out the baseplate and piston sleeve to the

stop, then push back again to the stop.

2a. If the movement is stiff, lightly spray the outer surface of the piston

sleeve with lubricant and slide in and out several times.

3. Insert the magazine into the base of the handgrip. Slide the magazine

upwards until it is flush with the bottom of the grip. Always insert

magazine from the bottom of the tool.

4. Press

tool

firmly and squarely against the work surface and squeeze

trigger.

NOTE: Tool must be perpendicular to work surface for best fastening

results.