reV: 17f

SMoGHoG

®

SHM Series Models

4

becomes increasingly difficult for either the carrier or the

supplier to assume responsibility for any damages after

too much time has elapsed. check all loads separately.

the following steps should be taken immediately

upon receipt of your shipment; this will assure and

expedite claim payments and replacement of missing or

damaged items.

1. Begin your inspection of the shipment Before it is

unloaded.

2. Check for damage to any exposed items, particularly at

the tie‐down locations.

3. Photograph any damage. do this Before the

equipment is unloaded.

4. check Bill of Lading quantities and description. note

any discrepancies on all copies of the Bill of Lading

and have them acknowledged (the carrier should sign).

damage description should also be written directly on,

or attached to, the Bill of Lading, and should also be

signed by the driver.

contact the insurance company and the shipper at once

so that damages and/or shortages can be corrected and a

claim can be filed without delay.

TIP OVER HAZARD

Lift the SHM unit and components by the packing

skids or on the lifting eye connection points located on

the top of the unit in each corner.

2.3 PRINCIPAL OF OPERATION

the purpose of the SHM is to collect fugitive mist generated

by various industrial processes during operation. the

collected contaminate is drained off of the coalescing

filters into the sump below. the sump is attached to a

drain system of the customers choice for recycling or

disposal.

do not let the oil level in the sump reach the height of

the lower tubesheet where the filters rest.

Differential Pressure

differential pressure, also referred to as pressure drop

(Δ P), is an indication of the resistance to airflow across

the filter elements. differential pressure is commonly

measured in inches of water column (W.c.) or Pascals

(Pa). it is normal for the differential pressure to increase as

the collector operates. any sudden increase or decrease

in differential pressure may indicate a problem in the

collector (blinded filters, leaks or other cause) that requires

immediate attention. See trouble shooting guide in Section

6 for assistance.

the operating differential pressure displayed on the

unit will typically run between 0.75 to 3 in. W.c. (187 to

746 Pa). The expected pressure range for the after-filters

is 0.5 to 3.0 in. W.c. (124 to 746 Pa).

3. INSTALLATION

3.1 INSPECTION AND OFF LOADING

as soon as your equipment arrives, it should be carefully

inspected to make certain that it is in good condition and

that all items listed on the packing list have been received.

even though the items are carefully loaded and tied

down at the time of shipment, it is possible for them to be

damaged or become dislodged in transit.

report any damage(s) and/or shortage(s) immediately. it

!

D A N G E R

CAUTION

Содержание SMOGHOG SHM-05C

Страница 1: ...Model SHM 05C Shown SMOGHOG Media Mist Collector l Models SHM 05C SHM 08C OWNER S MANUAL ...

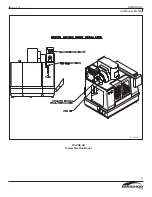

Страница 11: ...REV 17F SMOGHOG SHM Series Models 7 FIGURE 3B Typical Machine Mount 61 10144 ...

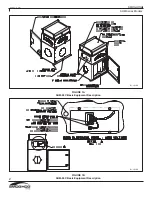

Страница 14: ...REV 17F SMOGHOG SHM Series Models 10 61 10129 Figure 4 Remote Panel Touchscreen Connection ...

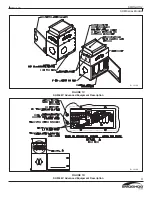

Страница 16: ...REV 17F SMOGHOG SHM Series Models 12 61 10133 Figure 5 SHM Filter Removal Installation ...

Страница 26: ...REV 17F SMOGHOG SHM Series Models 22 61 10134 Figure 22 ...

Страница 27: ...REV 17F SMOGHOG SHM Series Models 23 A1 BASIC UNIT 04 001990 ...

Страница 28: ...REV 17F SMOGHOG SHM Series Models 24 A2 REMOTE PANEL TOUCH CONTROLS 04 001802 ...

Страница 29: ...REV 17F SMOGHOG SHM Series Models 25 A3 ADVANCED UNIT WITH REMOTE CONTROLS 04 002235 ...

Страница 30: ...REV 17F SMOGHOG SHM Series Models 26 A4 575 480 TRANSFORMER 04 001717 ...

Страница 31: ...This page intentionally left blank ...