12

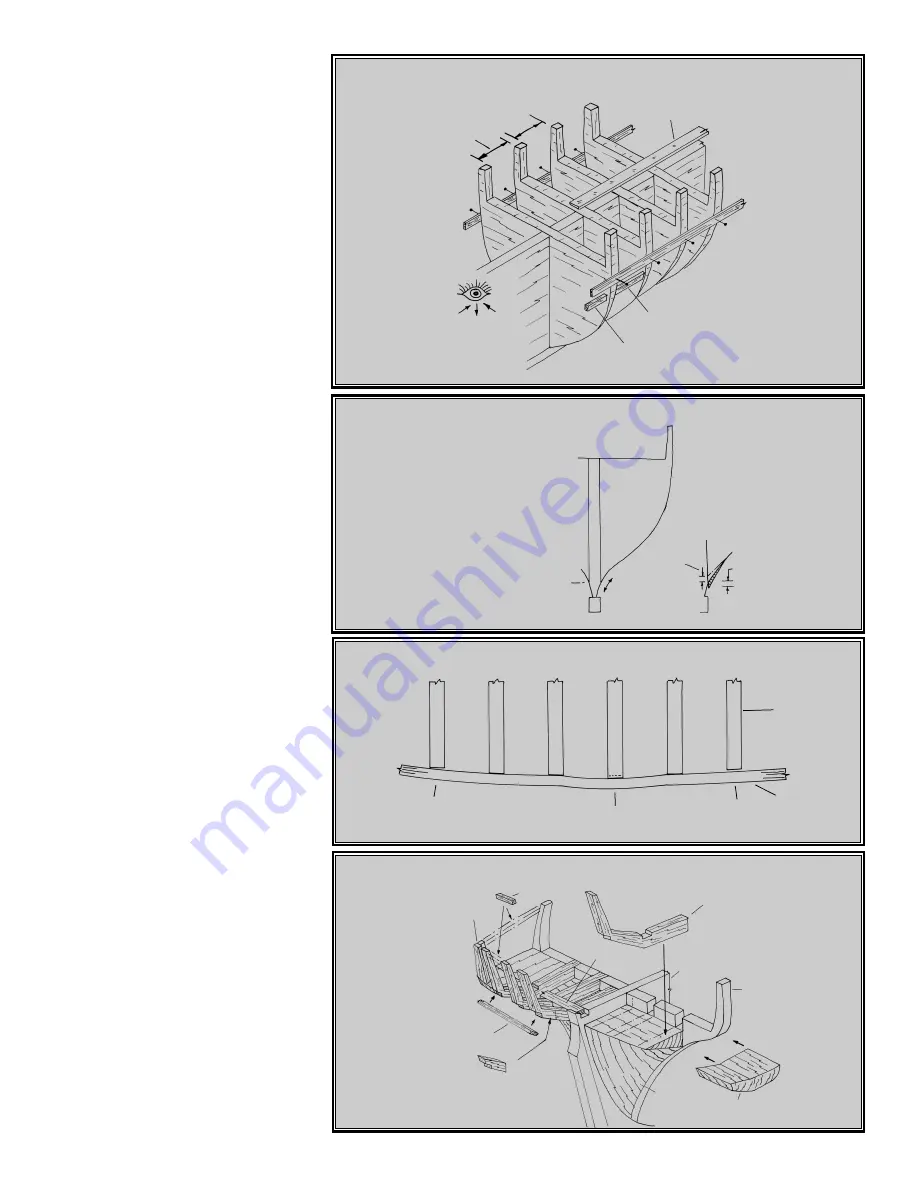

6. Installing the Stern Blocks

and Transom Framing

Refer to Sheet 2. Port and starboard

filler and corner filler blocks butt into

Bulkhead Q

and the center keel. They

provide more area on which to glue hull

planking. Some waterlines are included

to aid in carving these blocks to the cor-

rect hull form.

Mount the stern filler block, then install

the laser-cut stern timbers. Add the cor-

ner filler blocks. Glue the two horn tim-

bers to the sides of the center keel. Inner

and outer timbers fit into a slot in

Bulkhead Q

. Glue quarter stanchions to

the corner filler block. To form the hole

for the rudder stock, install the laser-cut

filler piece between the horn timbers.

Timbers have stiffeners between them,

while some gunports have filler pieces

for support. A deck beam fits into the slot

in the top of the stern timbers. Figure 1-9

shows the stern framing assembly. See

the plans for pictorial views.

7. Installing the Bow

Filler Blocks

After carving the bow filler blocks to

shape, add them forward of

Bulkhead

A

. They provide a solid base for tim-

berheads and knightheads, and addi-

tional support for the hull planking.

Planks will still need steam bending at

the bow; but, with the blocks in place,

are not as likely to break as they curve

around the last bulkhead.

8. Covering the Mast Slots

Cut the pieces shown on Sheet 2 from

scrap wood, then glue to both sides of

the two mast slots in the center keel.

Make sure they are securely fastened,

because access to them is impossible

once the deck is laid.

9. Installing the Waterway

and Planksheer

Apply glue to the scarf joints of the

three-piece waterway. When dry, shape it

to fit per the plans. Most shaping occurs

toward the bow. Now install it against

the timberheads.

Add the three-piece, laser-cut planksheer

on top of the waterway. It also requires

some shaping, especially at the bow.

The planksheer has built in gunport

sills, carronade carriage-pin holes, and

timberhead slots. The latter requires

precisely spaced bulkheads. If this is

Fig 1-6 Temporary Battens for Hull Alignment

Fig 1-8 Checking Hull Fairness with a Batten

Fig 1-9 Stern Framing

Fig 1-7 Correcting Bulkheads at Bearding Line

Check keel with

straight edge

Check spacings

Tack temporary

strip both sides

Optional permanent

strut between

bulkheads

Check alignment

visually in all

directions

Bearding Line

Bulkhead

Batten

Needs shim

Needs trim

O.K.

O.K.

O.K.

Needs trim or shim depending on

fairness with next bulhead

Quarter stanchion

Top stiffeners

Stern timber

(laser-cut)

Arch board

Fill piece between

horn timbers

(laser-cut)

Deck beam

Center keel

Bulkhead “

Q

”

Corner filler

block

Filler

block

Add shim

Trim

Smooth flow

into rabbet