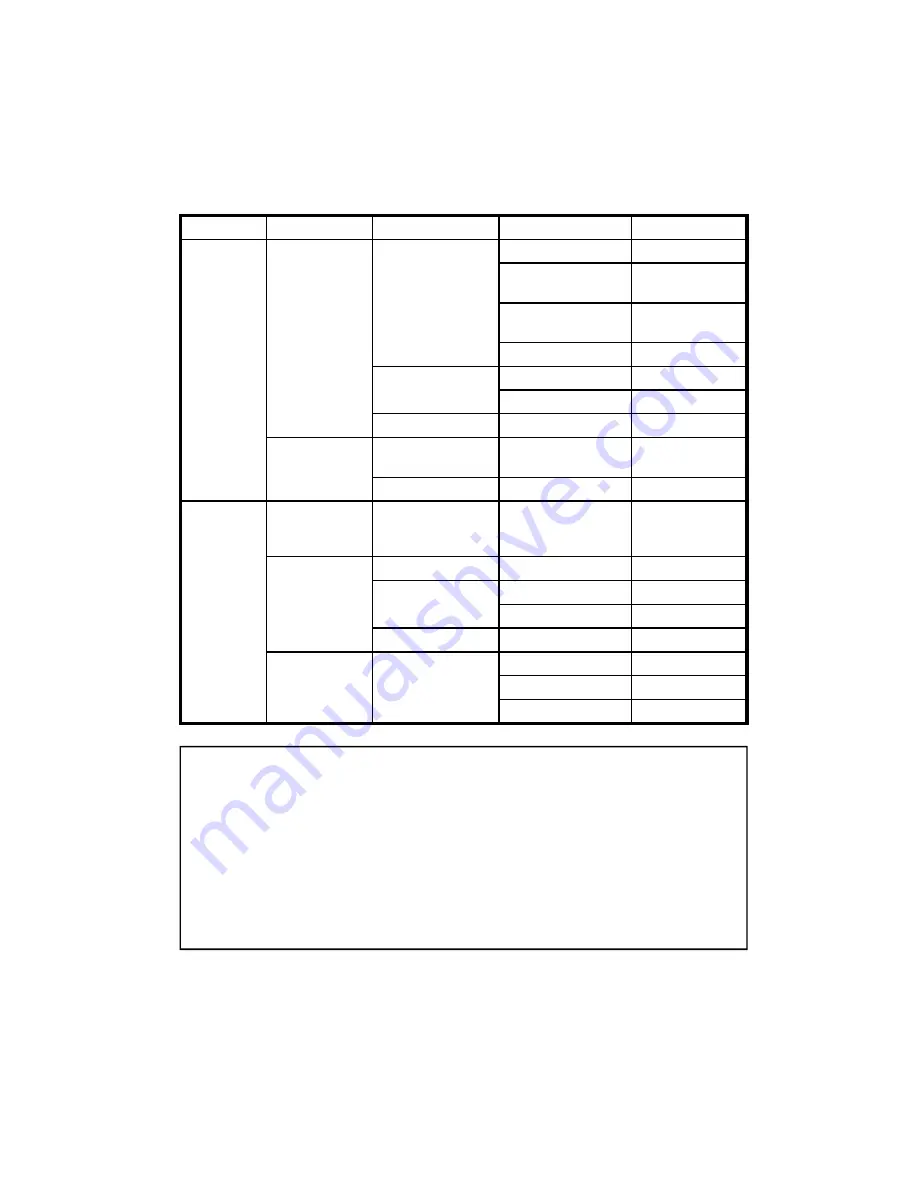

SYMPTOM

CONDITION

CAUSE

REMEDY

2.Motor

Weak from

pressure or don”t

work

Motor is normal

Air inlet clogged

Remove

Evaporator freezing

Controlling

minimum pressure

Ventilator switch

damage

Replace the switch

Compressor

Replace

Motor is abnormal

Motor failure

Replace

Wire cut

Replace

Air leakage

Duct leakage

Check,tighten

Unable to control

the fan

Motor

Air volume control

switch failure

Check,tighten

Motor is abnormal

Motor failure

Replace

3. Clutch

Noise

Regular noise

Irregular noise

Interference with

pulley

Control the

compressor

direction

Disengage

Engaged sometimes

Wire defect

Check wire

Engaged to push

Clutch gap large

Adjust

Engaged to push

with hand

Clutch gap large

Adjust

Low voltage

Check battery

No defect wire

malfunction

Replace

Slip

Slip during rotation

Low voltage

Check battery

Oil stick at clutch

Clean

Malfunction

Replace

(2) How to check the air conditioning system with the needle of high low gauge

To connect with manifold pressure gauge can find the cause of air conditioning system.

Because manifold pressure gauge is various sensibly (Ambient Temp. is based on 30~35

℃

)

Caution

:

Operating E/G RPM 1500~2000 is must, and so to that you can check the correct cause

and air conditioning.

(In case below the figure of indicated pressure gauge has some clearance, confirm with approximate

indicated needle data.)

Gauge pressure conversion

●

lb/in² = PSI

●

1 kgf/

㎠

=14.22 lb/in²

(Ex) 200 PSI =14 kgf/

㎠

92

Содержание T603

Страница 2: ......

Страница 34: ......

Страница 82: ......

Страница 105: ...T603 CABIN WIRING DIAGRAM A3 103 ...

Страница 106: ......

Страница 107: ...T603 ROPS WIRING DIAGRAM A3 105 ...

Страница 108: ......

Страница 109: ...T603 WIRING DIAGRAM FOR POWER SHUTTLE If equipped 105 ...

Страница 110: ......

Страница 111: ...WIRING DIAGRAM 107 ...

Страница 112: ...CABIN WIRING DIAGRAM 108 ...

Страница 113: ...CABIN WIRING DIAGRAM 109 ...

Страница 115: ... T603 POWER TRAIN 111 ...

Страница 116: ... T603 POWER TRAIN FOR POWER SHUTTLE If equipped 111 ...

Страница 117: ...DATE JOB CARD NO NATURE OF DEFECT PARTS REPLACEMENT W CLAIM NO AND DATE REMARK S TRACTOR HISTORY CARD 112 ...

Страница 118: ...DATE TRACTOR HOURS NATURE TYPE OF REPAIR SERVICE CARRIED OUT SERVICE RECORD 113 ...

Страница 119: ...DATE JOB DONE MACHINE HOURS FUEL CONSUMPTION ENGINE OIL TOPPED UP REMARKS START END DAILY OPERATION LOG 114 ...

Страница 120: ...PART REPLACEMENT RECORD DATE PART DESCRIPTION QTY COST DATE PART DESCRIPTION QTY COST 115 ...

Страница 121: ...T603 Operator s Manual for Tractors Code No 1995 940 002 1 Printed on August 2008 3rd Edition ...