Installation & Service Manual

TLM, TLF, TLD

Page 9

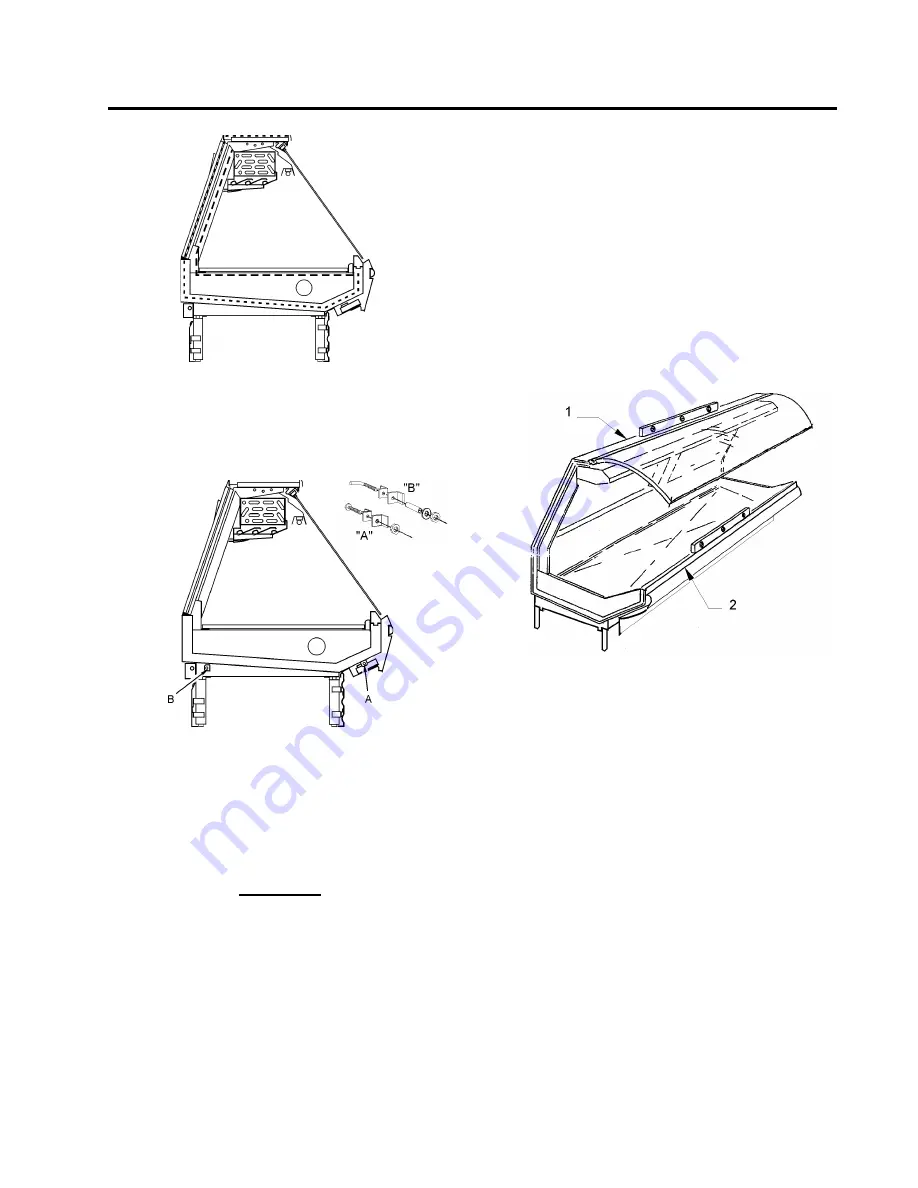

Lift Front Glass Leveling Instructions

Accurate leveling is critical for the proper

operation of the lift glass on this case.

In some instances, setting the case on an

apparently level floor can cause the lift glass

to fit improperly. If there is any twist in the

body, it could cause the lift glass not to fit

or work properly.

The emphasis when leveling this case must

be on making sure the lift glass works and

seals properly.

The case should be leveled across the top (1),

close to the hinge, and on the top of the front

cladding (2). A 4 foot level is recommended,

and

both places should be level!

This will

enable the lift glass to fit and work properly.

If the lift glass still doesn’t close or line-up

properly, adjust the legs at the case corners

or shimm the pedestals. Leg adjustment or

shimming will ensure proper operation and

alignment of the lift glass.

The handle on the lift glass must rest evenly

on the front cladding. Proper lift glass sealing

is essential for good product refrigeration.

NOTE

Do not anchor the base to the floor or

enclose the case until the lift glass is

fitting properly and working correctly.

3. Apply two heavy beads of caulking

compound from the Filler Kit to the end

of case at dotted (. . .) and dashed (- - -)

lines. Proper caulking provides good

case refrigeration and sanitation.

4. Push cases tightly together making sure

the pull-ups are aligned.

5. Adjust legs or add shims under the end

pedestals, as required. Check leveling at

top of the case and on top of the front

cladding.

CAUTION

Do not drill or use other holes through the

case end for pull-ups. This may deform

the case end and could cause joint leaks

and/or poor refrigeration.

6. Position pull-up bolts and mounting hard-

ware at pull-up locations (A and B). Do

not tighten any pull-up hardware until all

of it has been installed. Tighten all pull-up

hardware equally starting at point A and

finishing at point B.

Do not overtighten.

September, 2004

Содержание Allegro TLD

Страница 5: ...Installation Service Manual TLM TLF TLD Page 5 April 2007 ...

Страница 6: ...TLM TLF TLD Page 6 April 2007 ...

Страница 14: ...Page 14 TLM TLF Domestic Export 50 Hz Case Circuits 4 6 8 and 12 Cases July 2005 ...

Страница 15: ...Page 15 July 2005 ...

Страница 16: ...Page 16 July 2005 ...

Страница 17: ...Page 17 July 2005 ...

Страница 18: ...Page 18 TLD Domestic Export 50 Hz Case Circuits 4 6 8 and 12 Cases July 2005 ...

Страница 19: ...Page 19 July 2005 ...

Страница 20: ...Page 20 July 2005 ...

Страница 21: ...Page 21 July 2005 ...