TCF&B ES-52

5

BAF Wheels

HIB, BCS

& BCN

Wheels

BC, RBA &

TBA Wheels

HRT & RTF

Wheels

FC & NFC

Wheels

RBO, RBW, RBR

MBO, MBR &

TBR Wheels

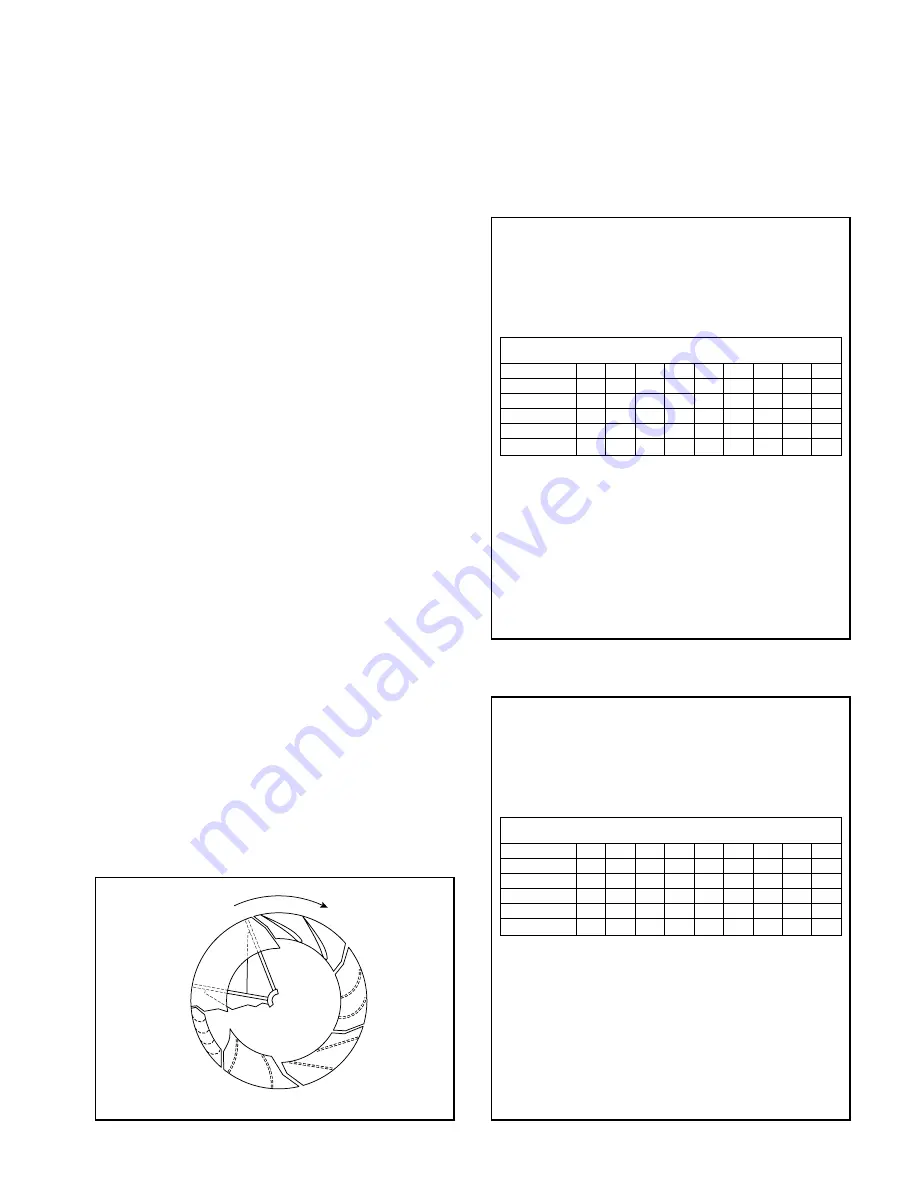

Rota

t

ion

Figure 7. Proper Wheel Rotation

WARNING

1. This equipment must not be operated without proper guarding of all

moving parts. While performing maintenance be sure remote power

switches are locked off. See AMCA Publication 410 for recommended

safety practices.

2. Before starting: Check all setscrews for tightness, and rotate wheel by

hand to make sure it has not moved in transit.

*Suggested initial greasing interval: Relubricate while running, if safety per-

mits, until some purging occurs at seals. Adjust lubrication frequency

depending on condition of purged grease. Hours of operation, tempera-

ture, and surrounding conditions will affect the relubrication frequency

required.

1. Lubricate with a multipurpose roller bearing NLGI No. 2 having rust

inhibitors and antioxidant additives, and a minimum oil viscosity of 500

SSU at 100ºF. Some greases having these properties are:

Shell - Alvania No. 2

Mobil - Mobilith AW2/Mobilith SHC100

Texaco - Premium RB2

American - Rykon Premium 2

2. Lubricate bearings prior to extended shutdown or storage and rotate

shaft monthly to aid corrosion protection.

WARNING

1. This equipment must not be operated without proper guarding of all

moving parts. While performing maintenance be sure remote power

switches are locked off. See AMCA Publication 410 for recommended

safety practices.

2. Before starting: Check all setscrews for tightness, and rotate wheel by

hand to make sure it has not moved in transit.

*Suggested initial greasing interval: Reubricate while running, if safety per-

mits, until some purging occurs at seals. Adjust lubrication frequency

depending on condition of purged grease. Hours of operation, tempera-

ture, and surrounding conditions will affect the relubrication frequency

required.

1. Lubricate with a high quality NLGI No. 2 or No. 3 multipurpose ball

bearing grease having rust inhibitors and antioxidant additives. Some

greases having these properties are:

Shell - Alvania No. 2

Mobil - Mobilith AW2/Mobilith SHC100

Gulf - Gulfcrown No. 2

American - Rykon Premium 2

2. Lubricate bearings prior to extended shutdown or storage and rotate

shaft monthly to aid corrosion protection.

Relubrication Schedule (Months)*

Spherical Roller Bearing - Solid Pillow Blocks

Speed (RPM)

500

1000

1500

2000

2500

3000

3500

4000

4500

Shaft DIA

1

3

⁄

16

" thru 1

7

⁄

16

"

6

4

4

2

1

1

1

1

1

⁄

2

1

11

⁄

16

" thru 2

3

⁄

16

"

4

2

1

1

⁄

2

1

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

2

7

⁄

16

" thru 3

7

⁄

16

"

3

1

1

⁄

2

1

1

⁄

2

1

⁄

2

1

⁄

4

1

⁄

4

3

15

⁄

16

" thru 4

15

⁄

16

"

2

1

⁄

2

1

1

⁄

2

1

⁄

4

Figure 8. Safety & Lubrication Instructions for Fans

with Ball Bearings

Figure 9. Safety & Lubrication Instructions for Fans

with Unit Roller Bearings

Relubrication Schedule (Months)*

Ball Bearing Pillow Blocks

Speed (RPM)

500

1000

1500

2000

2500

3000

3500

4000

4500

Shaft DIA

1

⁄

2

" thru 1

11

⁄

16

"

6

6

5

3

3

2

2

2

1

1

15

⁄

16

" thru 2

7

⁄

16

"

6

5

4

2

2

1

1

1

1

2

11

⁄

16

" thru 2

15

⁄

16

"

5

4

3

2

1

1

1

3

7

⁄

16

" thru 3

15

⁄

16

"

4

3

2

1

1

1

Lubrication

Proper lubrication of bearings helps assure maximum bear-

ing life. All fans are equipped with decals indicating relubri-

cation intervals for normal operating conditions. However,

every installation is different and the frequency of lubrication

should be established accordingly.

nance schedule given below.

Motors should be kept dry to avoid electrical short cir-

cuits. Motors kept in storage for long periods of time can

have moisture condense on the windings. Be certain the

motor is dry before using.

Some smaller motors are lubricated for life. Motor bear-

ing lubrication, if required, must follow a rigorous schedule.

Motors less than 10 hp running about eight hours a day in a

clean environment should be lubricated once every five

years; motors 15 to 50 hp, every 3 years; and motors 50 to

150 hp, yearly. For motors in a dusty or dirty environment or

running 24 hours a day, divide the service interval by 2. If the

environment is very dirty or high temperatures exist, divide

the service interval by 4. Lubrication requirements are nor-

mally attached to the motor. Do not overlubricate.

Drive Maintenance

V-belt drives need periodic inspection and occasional belt

replacement. When inspecting drives, look for dirt buildup,

burrs or obstructions which can cause premature belt or

drive replacement. If burrs are found, use fine emery cloth or

a stone to remove the burr. Be careful that dust does not

enter the bearings.

Check the sheaves for wear. Excessive slippage of belts

on sheaves can cause wear and vibration. Replace worn

sheaves with new ones. Carefully align sheaves to avoid

premature sheave failure.

Observe belts for wear. If fraying or other wear is

observed to be mostly on one side of the belts, the drives

may be misaligned. Reinstall the drives according to instruc-

tions given for Fan Installation of Disassembled Units, part

9. Never use belt dressing on any belts.

When replacing belts, replace the entire set. After initial

replacement and tensioning, recheck belt tension after a few

days to adjust belt tension again. (New belts require a break

in period of operation.)

Bearing Maintenance

For instructions covering special lubrication intervals, bear-

ing assembly or disassembly, or installation details, see

attached documents. Any bearing which is disassembled

should be kept separate from other bearing parts as com-

ponents may not be interchangeable. Maintain cleanliness

of components and bearings to prevent bearing contamina-

tion.

Bearing failure can occur from many causes. See

Troubleshooting section for details.

Note: All speeds shown do not apply to all shaft sizes in that

group. Consult the factory if in doubt of maximum speed for

a particular bearing.