14

8. Inspect all moving and rotating parts.

Remove any debris that has become

entangled in the rear beaters or the PTO

drive line.

9. Make sure that all guards and shields are

installed and secured in position.

10. Check the oil level in the gearboxes. Top

up as required.

11. Insure that the PTO driveline is securely

attached on both ends and can telescope

easily. Check that the PTO driveline shield

rotates freely.

Loading

IMPORTANT :

When parking the spreader for

loading, put the tractor in

PARK

or

NEUTRAL

and apply the parking brake.

1. Fully Close Rear Hydraulic Gate

2. Load the Spreader

The manure consistency will determine

how full your spreader can be loaded. Solid

manure can usually be loaded level to slightly

heaped. Wet materials are heavier and may

limit loading.

NOTES: It is unlawful to allow any manure

spillage to occur on public roadways. Do not

heap load such that manure is allowed to fall off

spreader during transporting on roadways.

Always check the apron chain and slats to make

sure they are not frozen to the bottom of the

bed. Operating the spreader when the slats or

chain are frozen to the bed may cause damage.

Also make sure there are no lumps of manure

frozen to the floor.

It is recommended to make sure the apron

chain is operating properly before loading the

spreader.

Pre-operation Checklist

It is important for both personal safety and

maintaining the good mechanical condition

of the machine that this pre-operational

checklist be followed. Before operating

the machine and each time thereafter, the

following areas should be checked off:

1. Lubricate the machine completely. Refer

to “Service” in the Service & Maintenance

section of this manual.

2. Use only a tractor of adequate power

(see PTO / Horsepower Requirements on pg.

12) and weight to handle the spreader.

3. Ensure that the machine is properly

attached to the tractor using a drawbar pin

with provisions for a mechanical retainer.

Make sure that a retainer is installed.

4. Ensure that the safety chain on the hitch

is installed.

5. Check tires and ensure that they

are inflated to the specified pressure:

25 psi (175 kPa).

6. Check oil level in the tractor hydraulic

reservoir. Top up as required.

WARNING : Use extreme care when

working around a high pressure hydraulic

system. Make sure all connections are

tight and all components are in good

repair. Wear hand and eye protection when

searching for suspected leaks.

7. Inspect all hydraulic lines, hoses,

fittings and couplers for tightness.

Tighten if there are leaks. Use a clean

cloth to wipe any accumulated dirt from the

couplers before connecting to the tractor’s

hydraulic system. See “Hydraulic Safety” in

the Service & Maintenance section of this

manual.

Содержание Nitro 450

Страница 1: ...Tube Line Manure Spreader Nitro 450 Operator s Manual 31375 Rev 1 3 Nov 11 2014...

Страница 23: ...23 Part Lists...

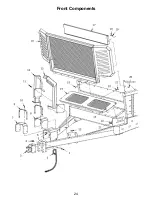

Страница 24: ...24 Front Components...

Страница 26: ...26 Rear Components...

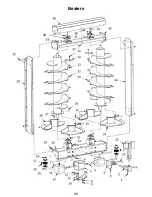

Страница 28: ...28 Beaters 34...

Страница 30: ...30 Apron Drive 20...

Страница 32: ...32 Apron Runners...

Страница 34: ...34 Side Floor Boards...

Страница 36: ...36 Single Axle...

Страница 38: ...38 Tandem Axle...

Страница 40: ...40 Drive Line 11 12...

Страница 42: ...42 Endgate Hydraulics...

Страница 44: ...44 Chain Drive Hydraulics...

Страница 46: ...46 Grease Line Schematic...

Страница 48: ...48 Intentionally Blank...

Страница 49: ...49 Light Kit TLVLK 450 Available Options...

Страница 50: ...50 Lights Right Left...

Страница 52: ...52 Light Kit Hydraulics...

Страница 54: ...54 Light Kit Electrical Breakdown...

Страница 56: ...56...

Страница 57: ...57...

Страница 58: ......