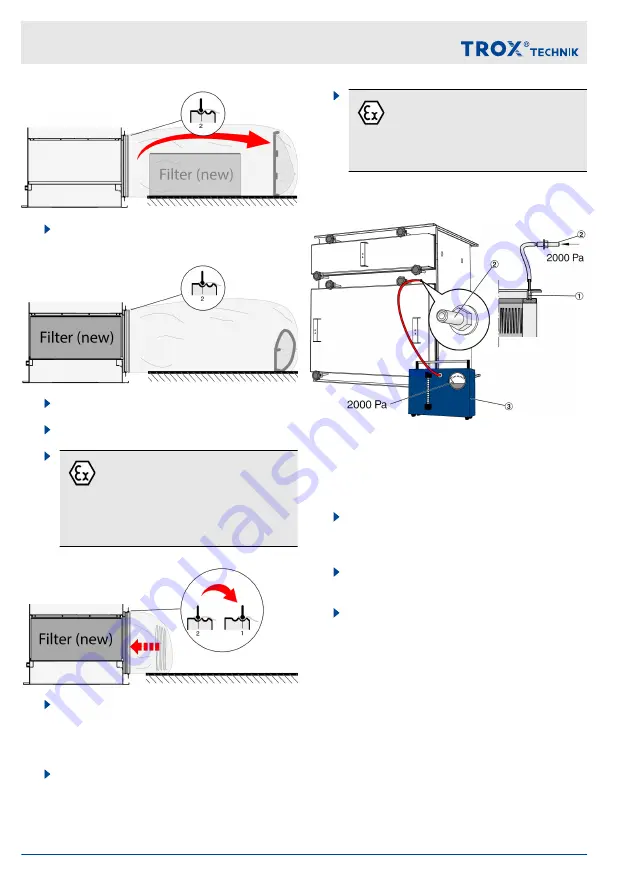

10.

Remove the old maintenance sack from

groove 1 and place it behind the new filter.

11.

Pushing the new filter into the casing

12.

13.

EXPLOSION HAZARD!

KSFS-...-Ex: Connect the earthing cable

to the filter element with the blade con-

nector (Fig. 2/3).

14.

Move the maintenance sack with the ring

seal from groove 2 onto groove 1. Roll up

the maintenance sack and place it in the

casing.

15.

Close the casing, Fig. 14.

16.

EXPLOSION HAZARD!

KSFS-...-Ex: Mount the earthing cable

from the filter chamber cover (Fig. 2/2).

Sealing integrity test

Fig. 15: Sealing integrity test

The casing is fitted with a sealing integrity test

facility. Sealing integrity is tested with a sealing

integrity test device (see operating manual).

1.

Connect the sealing integrity test device

(Fig. 15/3) to the connection point on the

filter (Fig. 15/2).

2.

Apply at least 2000 Pa to the test groove

(Fig. 15/1).

3.

Check the leakage rate on the flow rate

meter of the sealing integrity test device.

ð

The value must not exceed 0.003% of

the nominal volume flow rate.

If this value is exceeded, adjust the clamping

screws or the clamping frame; also check the seal,

test groove and filter element for damage. Then

repeat the sealing integrity test.

Maintenance

KSFS

∙

KSFS-...-Ex Ducted particulate filters

14