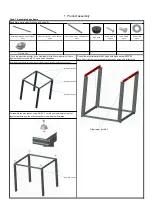

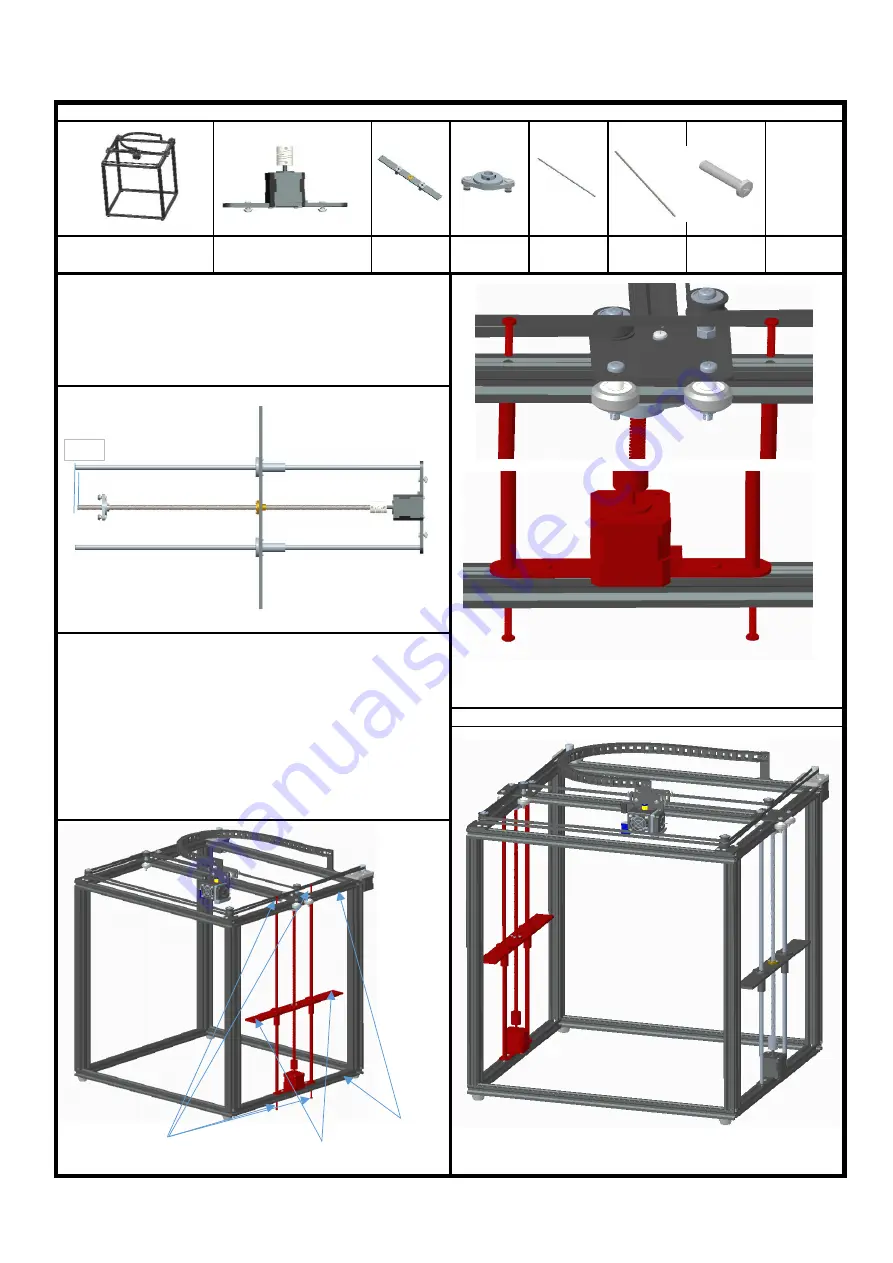

Alu. Profile 2

PM4*20

Sliding rod

Φ8*528 4pcs

Z motor component 2pcs

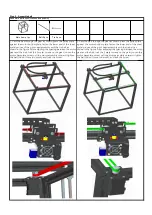

1.Insert the solid end of the Sliding rod to the hole on Z axis motor holder, insert the barrel of the

motor holder into the hole

,

do not let the pole stand out,same as the illustration.Then, put the Z

fixed plate component with the pole Φ8*528 together. Thread the the lead screws T8*453 through

the copper nut, connect with the coupling hole on the motor,put the bearing seat component on

lead screw T8*453 same as illustration

(

The T nuts are at the outer end),then the Z axis carriage

is finished. Total need to assemble 2set.

Lead screw

T8*453 2pcs

Step 7

:

Assemble Z axis component

Assemble parts specifications and quantity

:

Bearing seat

component

2pcs

Screw PM4*20

8pcs

Note:When assemble the pole, keep lead screw T8*453 3mm shorter than sliding rod Φ8*528mm

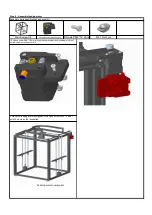

3.Repeat the number 2,assemble other Z aixs carriage, as the illustration.

Z carriage

2pcs

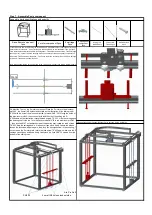

2.Adjust the T nut on the Z motor component, Place the Z motors to the aluminum

profile 2 , the 2 small M3 holes stand outsite as the illustration. Align sliding rod Φ

8*528 with the hole of the aluminum profile, let screw PM4 * 20 through the holes of

the aluminum profile 2, then connect with the M4 hole of the sliding rod Φ

8*528,same as the illustration, rotate the lead screws T8*453

,

slide the carriage and

the bearing seat to the top, lock the 2pcs screws PM4*20 to the aluminum profile 2

,

then lock the M4 T nut and jackscrew of the bearing seat, rotate the lead screws

T8*453, drop the carriage down

,

make sure it can move freely. Otherwise, please

loosen the jackscrew,adjust it again. then, lock the 4pcs jackscrew in the coupling , T

nut, screw on the Z motor plate, rotate the lead screw T8*453 again,make sure the Z

carriage can slide up and down freely. finally lock the 2pcs PM4*20 screws from the

bottom of the sliding rods .

Base frame component

1pcs

2 small M3 holes stand outside

3mm