Prestige SOLO 110 and EXCELLENCE

Natural to LP Conversion

4

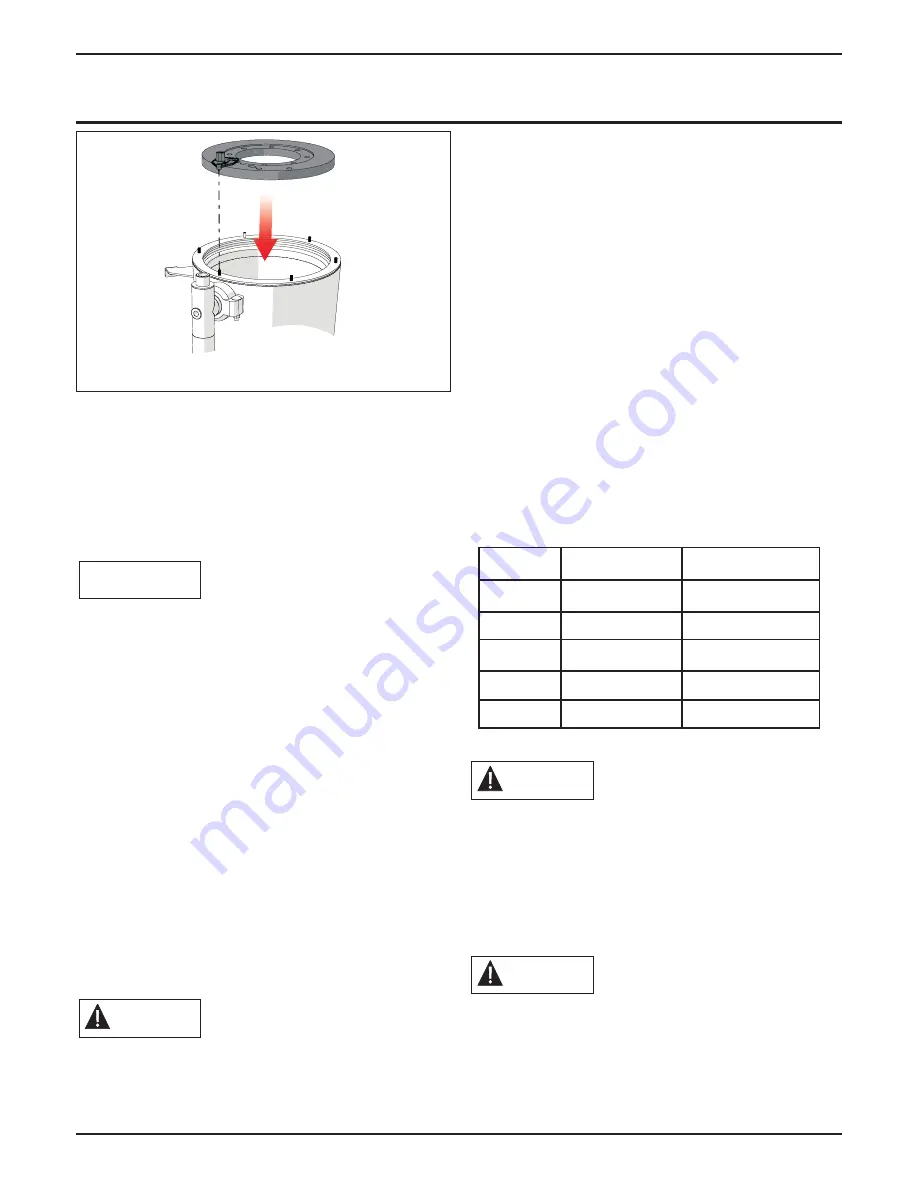

20. Check combustion chamber insulation alignment

with the burner mounting plate. The combustion

chamber insulation igniter cutout should align

with the opening in the burner mounting plate. If

not properly aligned, remove the burner mount-

ing plate and reposition combustion chamber

insulation.

Misalignment of combustion chamber insulation

can cause unreliable boiler operation.

21. Hand tighten the burner mounting plate nuts to

hold the burner plate in place. Once all mount-

ing nuts are in place, use a wrench to tighten

using an alternating pattern until the gasket is

slightly compressed. See Table 2, page 7 for

torque specifications.

22. Re-assemble the blower onto the burner mount-

ing plate and reconnect the wiring harness con-

nectors. Tighten screws evenly. See Table 2,

page 7 for torque specifications.

23. Re-assemble the gas supply connection and

wire harness to the gas valve. Tighten the union

using two wrenches. See Table 2, page 7 for

torque specifications. Open the external manual

gas valve. Check gas piping for any leaks and

repair if necessary.

Do not check for gas leaks with an open flame.

Use a bubble test. Failure to check for gas

leaks can cause severe personal injury, death

or substantial property damage.

24. Re-attach the ignition cable (MCBA) and the

ground wire to the ignitor.

25. Reattach the air inlet elbow to the venturi.

26. Reposition the control panel.

27. Replace the front jacket panel and secure with

the thumb screw on the upper edge of the unit.

28. Install the top jacket access panel

29. Turn power to the unit “ON”. The unit is now

ready to be placed back into service.

COMBUSTION TEST/ADJUSTEMENT

The installer must perform a complete combustion

check to ensure the following combustion levels are

met at high and low input firing rates and the burn-

er is operating at optimum conditions.

The combustion testing and adjustments

must be performed by a qualified installer,

service agency or the gas supplier. All com-

bustion measurements must be perform with

calibrated equipment to ensure proper read-

ings and accuracy.

Failure to perform a complete combustion

test at both high and low input rates may

result in incomplete combustion and the pro-

duction of carbon monoxide, which can

cause severe personal injury, death or sub-

stantial property damage.

NOTICE

WARNING

WARNING

WARNING

Natural Gas

Propane

O2 Min.

2.30%

2.70%

O2 Max.

5.30%

4.70%

CO2 Min.

8.80%

10.70%

CO2 Max.

10.50%

12.00%

CO Max.

100 ppm

100 ppm

Table 1: Recommended Combustion Levels

Fig. 5: Combustion Chamber Insulation Installation