4

IMPORTANT PRE-INSTALLATION NOTES

Before installation, it is imperative that the following guidelines are heeded to ensure the trouble-free and efficient

operation of the boiler:

Ventilation and Siting

When siting the boiler in a confined space it is essential that adequate ventilation be provided. This will ensure that air can

circulate freely around the appliance keeping down the ambient temperatures. Refer to Ventilation requirements (Page 11)

for further details.

Ensure that the area surrounding the boiler is kept free of items which would impede the good ventilation of the appliance

(e.g. towels, linen, etc).

When siting the boiler, consider the potential requirement for future servicing. Enough space should be provided at the front

of the boiler to enable an engineer to adequately service and/or replace items such as the PCB or heat exchanger. Space

should also be available for the removal of the front casing panel. Please refer to siting information (Page 11) for clearance

dimensions. The boiler must be sited vertically and away from strong magnetic fields.

Power Supply and Wiring

The power supply to the premises must meet the minimum requirements of the unit being installed, with special attention

paid to the supply current, cable size, and RCD recommendation. The supply voltage to the appliance must never drop below

207 Volts

.

System

Isolation valves must be fitted on both the flow and return pipe work. These are useful as from time to time the boiler may

require draining of water, and the lengthy drawing-off process can be avoided by the astute placement of these valves.

Ensure that any isolation valves are open before first use, and that the system is full of water.

IMPORTANT:

General Information:

To keep your boiler running efficiently DO NOT OBSTRUCT OR COVER any ventilation air inlet on the appliance or the

compartment where it is installed.

To keep the casing clean, switch ‘OFF’ the boiler at the electrical supply, and simply wipe with a damp cloth. DO NOT use

abrasive cleaning fluids as this may damage the stove enamel paintwork.

Содержание Aztec Mini

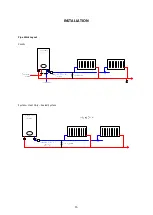

Страница 15: ...15 INSTALLATION Pipe Work Layout Combi System Heat Only Sealed System ...

Страница 20: ...20 BOILER SPARES ...