16

TRI TOOL INC.

92-0660 : Rev. 080423

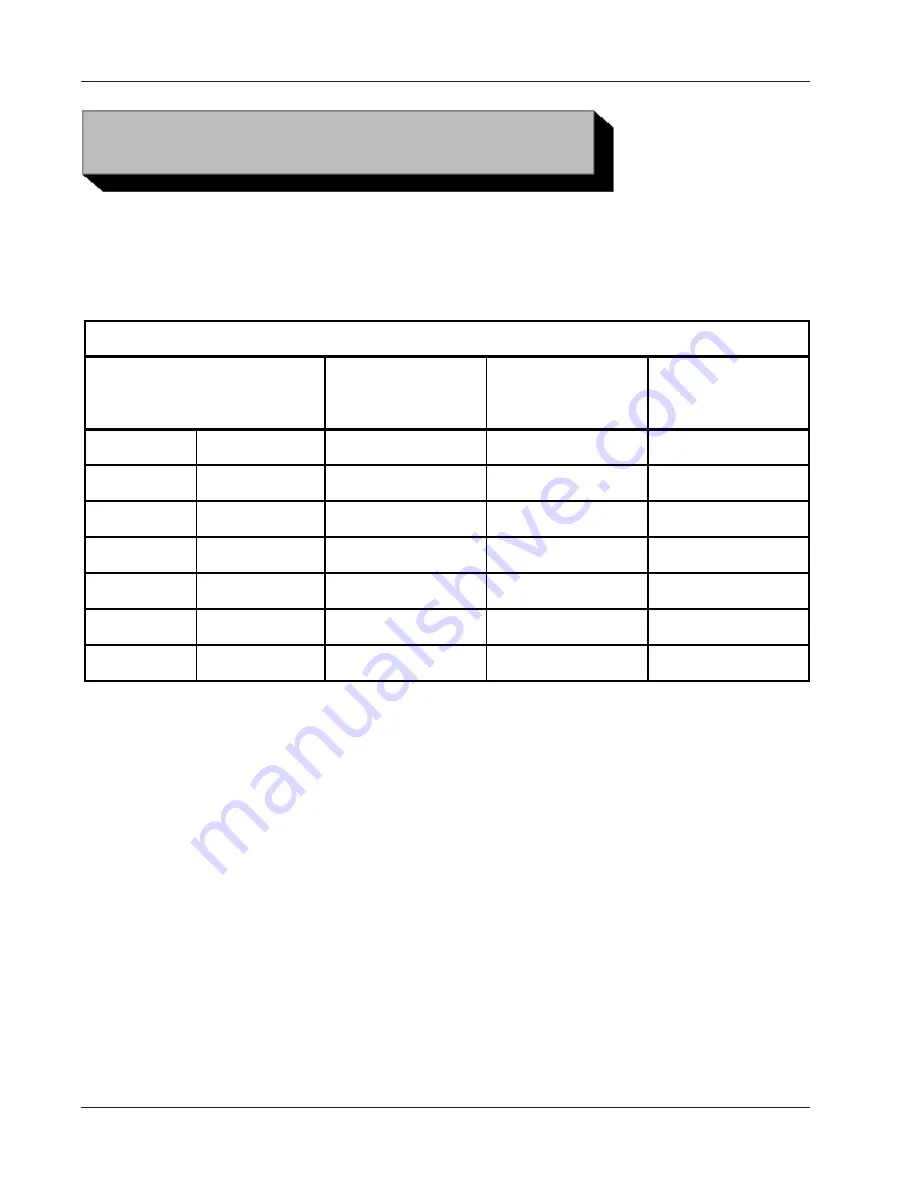

CUTTING SPEEDS AND FEEDS

CUTTING SPEEDS

The chart below shows RPM required to obtain a specified Tool Bit cutting speed on

the surface of a pipe or tube.

Use 200 surface inches per minute (5080 surface millimeters per minute) for:

Stainless steels in general when no coolant is allowed, all heavy wall tube and some

of the chrome/molybdenum alloys.

Use 250 surface inches per minute (6350 surface millimeters per minute) for:

Mild steels and some thin wall stainless steels when coolants are permitted and

used.

Use 300 surface inches per minute (7620 surface millimeters per minute) for:

Aluminum and thin-wall mild steel tube with coolant.

CUTTING FEEDS

Use very light feed for initial severing or until a continuous cut is established.

Use a feed rate .002” to .003” (.05mm to .08 mm) per revolution once a continuous

cut is established.

RPM for

200 in/min

(5080 mm/min)

RPM for

250 in/min

(6350 mm/min)

RPM for

300 in/min

(7620 mm/min)

.25"

6.4 mm

255

318

382

.38"

9.5 mm

169

209

251

.50"

12.7 mm

127

159

191

.75"

19.1 mm

85

106

127

1.00"

25.4 mm

64

80

95

1.50"

38.1 mm

42

53

64

2.00"

50.8 mm

32

40

48

Tube Size

Cutting Speeds (Approximately)