Model 601SBM Low Profile Clamshell

92-0092 Rev. 210701

15

Drive Gear and Main Gear Lubrication

Remove the Drive Housing.

Inspect both Drive and Main Gears for chips or burrs and clean as required.

Coat the teeth of the Drive Gear and the Main Gear with a grease which is approved by

TRI TOOL Inc. Refer to the Tripper Block Assy. Lubrication and Tripper Shaft adjustment

located later in this section.

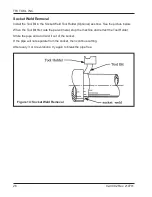

Tool Block Maintenance

Clean the Slide Rails, the Feed Nut, the Sprocket Assy. and the Feed Screw.

Inspect these parts for damage and replace as required.

Lubricate and reassemble the Tool Block. Refer to the Tool Block Assembly.

NOTE:

Use lubricant on the Feed Screw sparingly or wipe to a film condition.

Excess lubricant will collect grit and/or chips and tend to cause thread jamming and/or

damage.

Adjust the Adjustable Slide Rail to provide a firm, but not excessive rotational pressure on

the Sprocket.

The Slide Rails must be over-tightened to squeeze the oil into a thin film against the male

and female surfaces of the Slide Rails.

Reset for proper operation.

NOTE:

If the Mounting Bracket has been overstressed, the Slide Rails may appear to

loosen when mounted if they were adjusted off of the Clamshell.

Adjustment when mounted provides the most satisfactory results.

Содержание 601SBM

Страница 1: ...Operation Manual 92 0092 Rev 210701 Model 601SBM Low Profile Clamshell ...

Страница 42: ...TRI TOOL INC 92 0092 Rev 210701 40 13 ILLUSTRATED PARTS BREAKDOWN MODEL 601SBM CLAMSHELL SUB ASSEMBLY ...

Страница 44: ...TRI TOOL INC 92 0092 Rev 210701 42 HOUSING ASSY DRIVE P N 19 0285 5 1 2 4 7 9 8 6 3 ...

Страница 46: ...TRI TOOL INC 92 0092 Rev 210701 44 MOTOR ASSY AIR P N 57 0083 5 4 2 3 8 1 6 7 ...

Страница 48: ...TRI TOOL INC 92 0092 Rev 210701 46 TOOL BLOCK STANDARD P N 08 0036 2 7 6 10 11 12 13 8 3 4 5 9 9 1 ...

Страница 50: ...TRI TOOL INC 92 0092 Rev 210701 48 TOOL BLOCK LOW PROFILE P N 08 0096 1 7 9 8 5 3 2 11 6 4 3 10 ...

Страница 54: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 55: ......