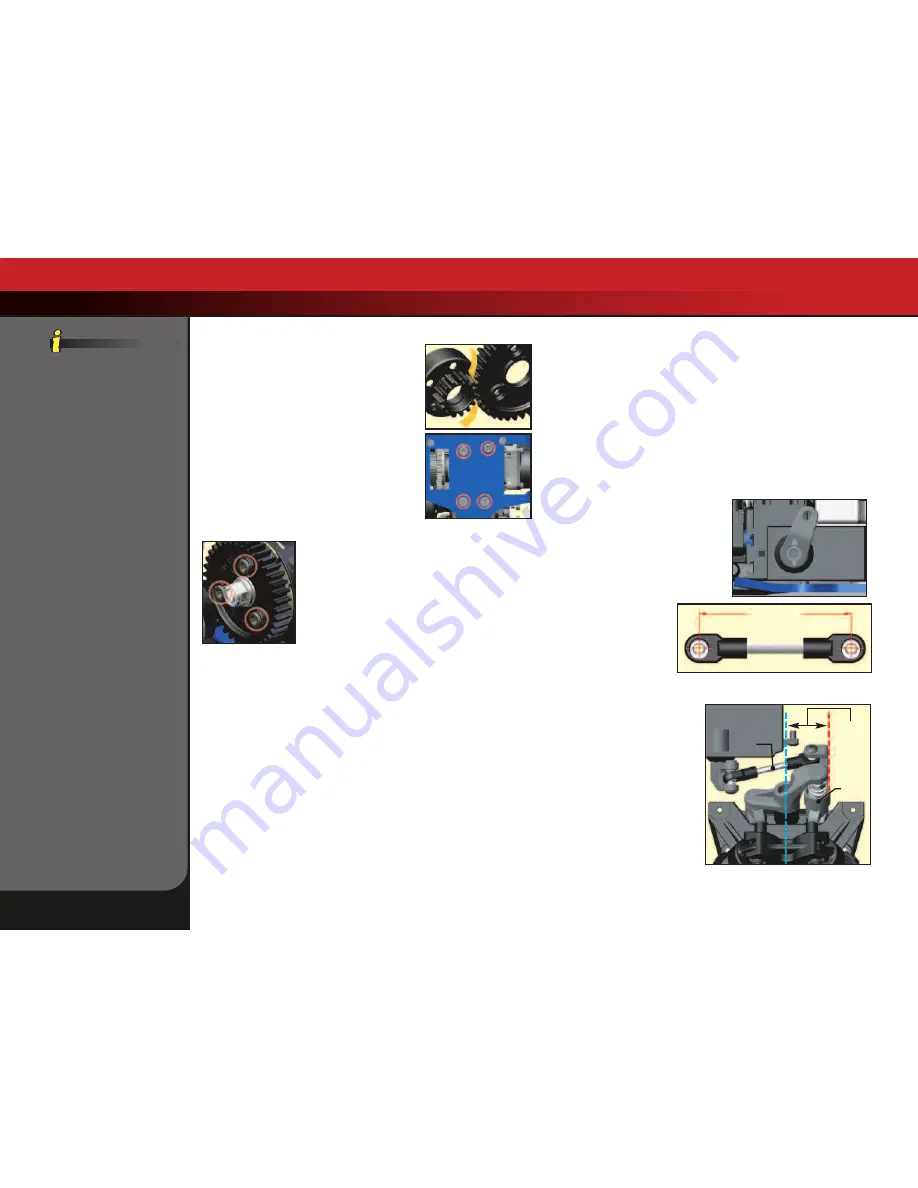

Adjusting the Spur Gear/Clutch Bell Gear Mesh

The ideal spur gear/clutch bell gear mesh for Jato is

0.1mm. To set the gear mesh, place a strip of

standard letter/A4 size copy or printer paper (about

0.1mm thick) between the mating teeth. Loosen

the four engine mount screws from the bottom

side of the chassis (see image) and slide the engine

mount up to push the clutch bell gear against the

spur gear so the paper is not too tight to pull out or

too loose that it will fall out. Tighten the engine

mount screws securely. When the paper is

removed, you should feel only the slightest amount

of play between the gears (almost none) and there

should be no binding or friction.

Changing the Spur Gear

Remove the three screws on the slipper clutch

assembly using a 2.5mm hex wrench. Slide the spur

gear off of the slipper shaft. If the spur gear is too tight

on the shaft, gently pry on the back of the gear with a

flat screw driver to loosen it.

Repeat the above steps in reverse order to install the

new spur gear. If the new spur gear is a different size,

then the engine mount screws will need to be

loosened to readjust the gear mesh (see above).

Steering System

Jato has a very sophisticated bellcrank steering system with geometry that is

designed to completely eliminate bump steer. Bump steer occurs when the

steering angle of the front wheels changes as the suspension moves up and

down through its range of travel. Suspensions that have bump steer make it

difficult to drive in a straight line over bumpy terrain. Jato tracks true no matter

how rough the course gets. An adjustable integrated servo saver protects the

servo gears and still permits precise feel and tight steering response.

Adjusting the Servo Saver

The servo saver can be adjusted by tightening or loosening the nut above the

servo saver spring. Tightening the spring will reduce the servo saver action

and provide more solid steering, especially in extremely rough environments.

However, as the servo saver spring is tightened, protection for the servo gears

is reduced. Consider tightening the servo saver spring when using more

powerful aftermarket steering servos, or servos that have metal gears.

Steering System Linkage

Precise installation and adjustment of the steering linkage is necessary to

maintain the proper factory geometry in the steering system. If you change

the steering servo or disassemble the steering linkage please follow these

instructions carefully.

Properly positioning the servo horn onto the servo shaft and carefully

setting the linkage length is required to maintain the correct steering

throw. Use the following procedure.

1.

With new or freshly charged batteries installed, turn on the transmitter

power switch followed by the receiver power switch.

2.

Set the steering trim on the transmitter to neutral (zero).

3.

Position the Jato so it is level and you can view the installed steering

servo from the front.

4.

Verify that the servo horn is positioned

so the arrow inscribed on the face

points straight up (see illustration).

5.

If it is not, remove the servo horn (by

removing the 3x6mm screw), rotate it

to the correct angle, (arrow pointing

up), and reinstall.

The steering servo link must

be assembled as shown in

the illustration below. Note

that the rod end on one end

of the steering link is rotated

45 degrees compared the

other rod end. The exact

center-to-center distance between

the hollow balls is 43.1mm.

When the steering link is installed

in the Jato, the edge of the left

bellcrank (servo saver arm) should

be parallel to the centerline of the

vehicle (see illustration). If it is not

parallel, adjust the length of the

steering link.

38 • Jato 3.3

Basic Tuning Adjustments

Steering Link Length Template

(actual size)

43.1mm

Optional servo horns are

available separately for use

with non-Traxxas servos.

Servo

Saver

Arm

Steering

Link

Parallel

Содержание 5509

Страница 1: ...owners manual MODEL 5509 ...

Страница 47: ......

Страница 48: ...owners manual 1 100 Klein Road Plano Texas 75074 1 888 TRAXXAS 060515 MODEL 5509 ...