1800 816 277

www.tti.com.au

15

Product HandBook

GlidePath

™

•

Check that the operation lever is in the closed (BYPASS) position.

•

Check that the spray boom isolating valve(s) adjacent to the tank is in the CLOSED position.

•

Open the ball valve on the tank’s discharge line.

•

Start the pump using the following procedure:

• Turn the fuel lever to ON, refer to Figure 6.

• If the engine is cold, turn the choke lever to ON.

CAUTION! Ensure the engine’s throttle is set to idle if the engine is cold.

Do not adjust the throttle to maximum speed until the engine has warmed

up.

•

Set the throttle lever to idle for cold starting. If restarting a warm engine, the throttle can be left at normal

engine operating speed.

•

For a manual start engine, turn the power switch to ON. Pull the recoil starter handle until the engine

starts, then back off the choke lever to OFF.

•

For an optional electric start engine, insert the key and switch the engine to ON and START. When the

engine starts, release the key, which will return to the ON position. Back off the choke lever to OFF.

•

Once the engine is warmed up, adjust the throttle to increase the engine speed to normal operating revs.

With the engine running, the pump will operate with the fluid bypassing back into the GlidePath’s tank.

•

When the engine needs to be stopped, turn the power switch to the OFF position.

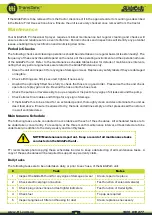

Figure 6 – Petrol Engine Start-up Procedure

•

With the pump running, turn the pressure regulator knob clockwise to the required pressure –

approximately 3 bar for spray boom operation. If the optional hose reel is fitted, approximately 5 bar is

required for hose operation. Refer to the calibration procedure described above for the actual required

pressure setting

•

For spraying operations, refer to:

• Hose Spray Operation

• Spray Boom Operation

If the GlidePath is not going to be used within the next few hours, shut the system down by turning the engine’s

fuel tap to OFF.