Page 5

Accessories

•

All electrical accessories must be installed and wired according

to the instructions packaged with the accessory.

Control Wiring (Class II)

•Low voltage control wiring should not be run in the same

conduit with the power wiring unless Class I wire of the proper

voltage rating is used. Route the thermostat cable or equivalent

single leads of No. 18 AWG colored wire from the thermostat

subbase terminals through the rubber grommet on the unit. See

Figure 1 for the control entry location. Make connections as

shown on the unit wiring diagram and in Figures 5 and 6.

•Do not short thermostat wires since this will damage the control

transformer.

•Recommended wire sizes and lengths for installing the unit

thermostat are provided in

Table 1: Thermostat Wire Size and

Maximum Length.

The total resistance of these low voltage

wires must not exceed one (1) ohm. Any resistance in excess of one

(1) ohm may cause the control to malfunction because of the

excessive voltage drop.

•IMPORTANT: Upon completion of wiring check all elec-

trical connections, including factory wiring within the unit.

Make sure all connections are tight. Replace and secure all

electrical box covers and access doors before leaving the unit or

turning on the power to the unit.

•After all electrical wiring is complete, set the thermostat system

switch on the

OFF

position so that the compressor will not run and

then apply power by closing the system main disconnect switch.

This will activate the compressor sump heat. Do not change the

Thermostat System Switch until power has been applied long

enough to evaporate any liquid HCFC-22 in the compressor. It is

recommended that the sump heat be energized for a minimum of

eight (8) hours prior to starting the unit.

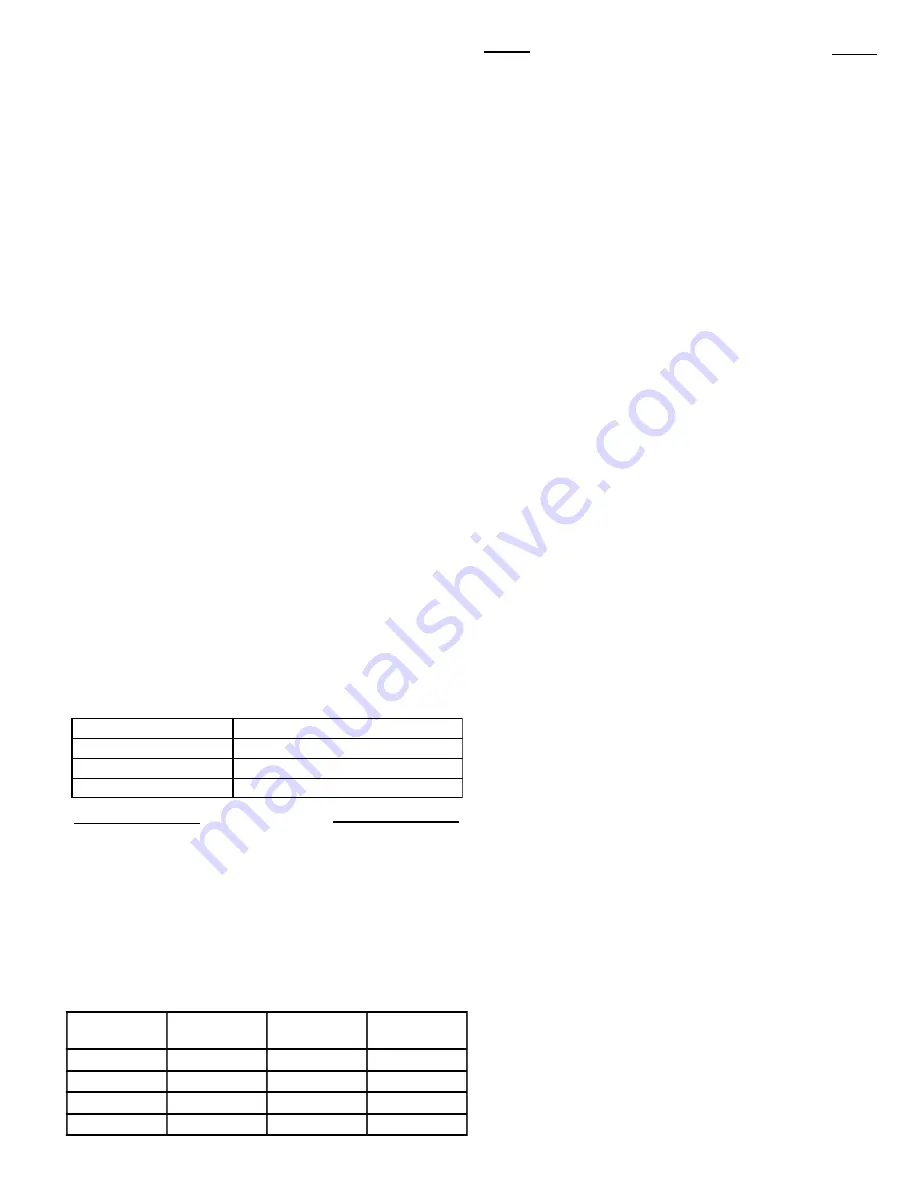

Table 1

Thermostat Wire Size and Maximum Length

WIRE SIZE

MAXIMUM LENTGH (Ft)

18

75

16

125

14

200

Table 2. Filter Data

Air Filters

•These units require filters with adequate filter area be pro-

vided in the return air duct. Table 2 below gives filter data. The

specific location of the filters depends on the type of installation

and the layout of the duct system. Be sure the owner is aware

of the location of the filter and the need to change them as

required. The Filter Size (Sq.. Ft.) are based on 300 F.P.M. face

velocity. If permanent filters are used, size per mfg. recommen-

dation with clean resistance of .05" WC.

UNIT

NOMINAL

CFM

FILTER*

(Sq Ft) SIZE

FILTER

RESISTANCE

WCK024B

800

2.67

0.05

WCK030B

1000

3.33

0.05

WCK036B

1200

4.00

0.05

WCK042B

1400

4.67

0.05

GENERAL

Operation of the unit heating and cooling cycles is automatic for

HEAT

and

COOL

functions. (The optional automatic changeover

thermostat, when in the

AUTO

position, automatically changes

to heat or cool with sufficient room temperature change.) The fan

switch can be placed in either the

ON

position, causing continu-

ous evaporator (indoor) fan operation, or the

AUTO

position

causing fan operation to coincide with heating or cooling run

cycles. Continuous fan mode during cooling operation may not be

appropriate in humid climates. If the indoor air exceeds 60%

relative humidity or simply feels uncomfortably humid, it is

recommended that the fan only be used in the AUTO mode.

COOLING MODE

(NOTE:

TSH

&

TSC

are contacts internal to the indoor thermo-

stat.)

With the disconnect switch in the

ON

position, current is

supplied to the compressor crankcase heater and control trans-

former. The cooling cycle is enabled through the low voltage side

of the control transformer to the

“R”

terminal on the indoor

thermostat. With the system switch in the

AUTO

position and

TSC-1

contacts closed, power is supplied to the

“O”

terminal on

the indoor thermostat to the switchover valve coil

(SOV)

. This

energizes the switch-over valve

(SOV)

and places it in the

cooling position (it is in the heating position when not energized).

When the indoor temperature rises 1-1/2 degrees,

TSC-2

con-

tacts close, supplying power to the

“Y”

terminal on the indoor

thermostat, and to the compressor contactor

(CC)

. This starts

the outdoor fan motor and compressor. The

TSC-2

contacts also

provide power to the

“G”

terminal which provides power to the

fan relay

(F)

and motor speed tap terminal and starting the

indoor fan motor.

HEATING MODE

With the disconnect switch in the

“ON”

position, current is

supplied to the control transformer. Starting at the

“R”

terminal

on the indoor thermostat, current goes through the system switch

(which is in

“AUTO”

position) to the

TSH-1

contacts. When

closed, these contacts supply power to terminal

“Y”

on the indoor

thermostat as well as to the heating anticipator. The switch-over

valve will not energize because of the high resistance of the

heating anticipator in the thermostat. Power is provided from

“Y”

to the compressor contactor

(CC)

which starts the outdoor

fan motor and compressor. The indoor thermostat contact

TSH-

1

also provides power to

“G”

terminal on the indoor thermostat

energizing the fan relay

(F)

, and motor speed tap terminal, which

starts the indoor fan motor

SUPPLEMENTARY HEAT

The supplementary electric heat

is brought on when the

indoor temperature drops 1-1/2 degrees below the thermostat

setting.

TSH-2

contacts close providing power to the

“W”

termi-

nal on the indoor thermostat and to the supplementary heater

control circuit.

NOTE:

The

fan relay

(F)

must have been energized.

An outdoor thermostat may have been added to disallow the

second stage (if provided) of electric heat above a selected outdoor

temperature. If the outdoor temperature falls below the setting

on the outdoor thermostat, this additional heater stage will come

on. When the outdoor air temperature rises, and the outdoor T-

stat setpoint is reached, the system will revert back to first stage

electric heating.

When the indoor ambient is satisfied,

TSH-2

contacts will open

Sequence of Operation