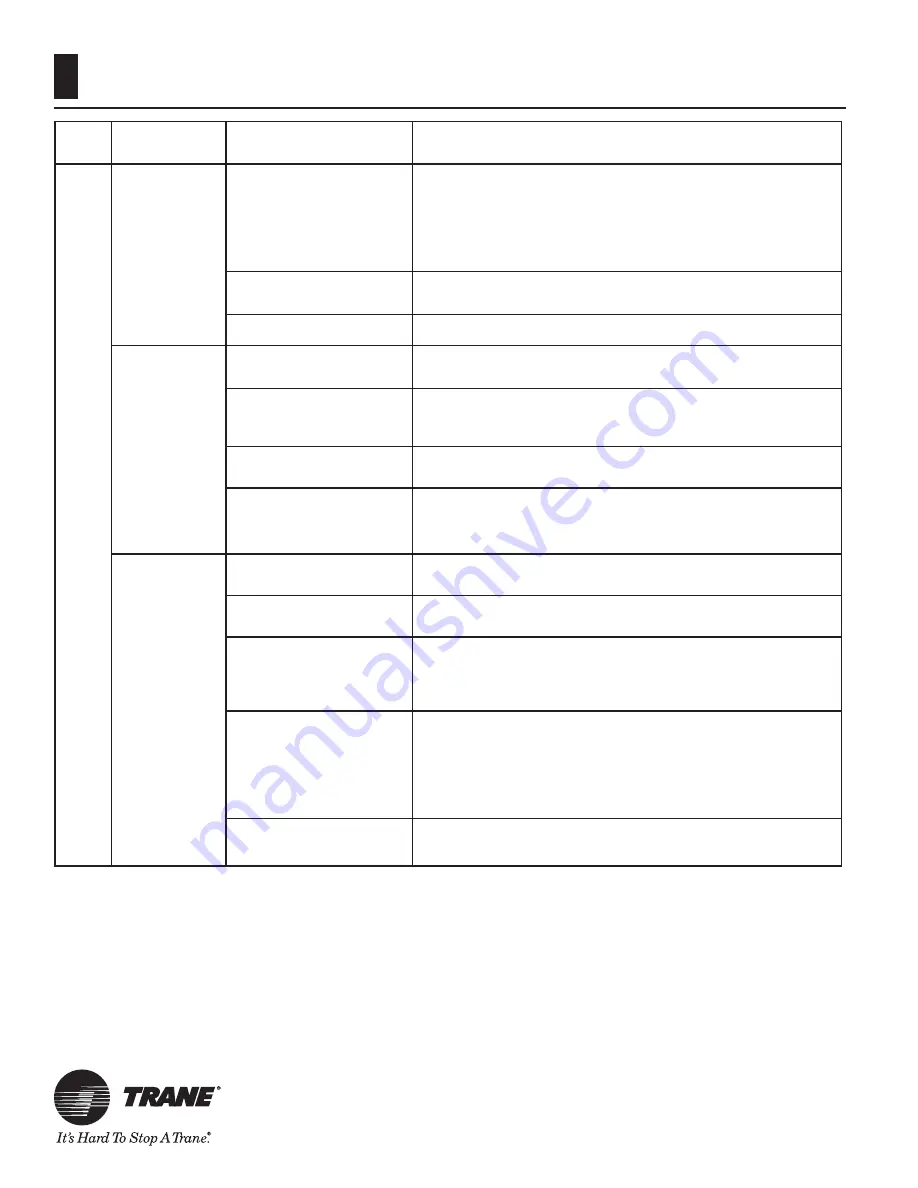

54

Code

Fault

Diagnosis Step

Remedy

None

Open FC1 and/

or FC2 Fuses.

1. Verify that 120VAC

Voltage Selector Plug

is not installed with a

240VAC fi eld power

supply.

Check that proper Voltage Selector Plug is installed. If OK,

proceed to step 2.

If 120VAC plug is installed and fi eld supply voltage is

240VAC, FC1 and FC2 fuses will have to be opened. Install

the correct Voltage Selector Plug and new FC1 and FC2 fuses.

2. Check for faulty

Transformer wiring.

Inspect Transformer wiring. Ensure insulation on wiring is not

worn. If OK, proceed to step 3.

3. Defective Transformer

Replace Transformer.

Open FC3 and/

or F1 Fuses

1. Check for faulty Gas

Valve wiring.

Inspect Gas Valve wiring. Ensure insulation on wiring is not

worn. If OK, proceed to step 2.

2. Verify that Gas Valve is

not defective.

Mesure for resistance across Gas Valve terminals and between

each terminal and ground. If short exists, replace Gas Valve.

If OK, proceed to step 3.

3. Check for faulty

Control Module wiring.

Inspect Control Module wiring. Ensure insulation on wiring is

not worn. If OK proceed to step 4.

4. Control Module is

defective.

Replace Control Module.

Open FC4

Fuse.

1. Check for faulty Igniter

wiring.

Inspect Igniter wiring. Ensure insulation on wiring is not

worn. If OK, proceed to step 2.

2. Check for faulty

Blower wiring.

Inspect Blower wiring. Ensure insulation on wiring is not

worn. If OK, proceed to step 3.

3. Check for defective

Igniter.

Disconnect Igniter plug from Control Module. Measure

resistance across Igniter. Resistance should be 10.9-19.7 ohms

at at 77°F. If out of this range, replace igniter. If OK, proceed

to step 4

4. Check for defective

Blower.

Disconnect Blower plug from Control Module. Measure

resistance across Blower windings. Winding resistance across

lead should be in the fo

llowing range: Red-to-White: 4 to

5 ohms. If measured values vary substantially from these

values, blower is defective. Replace. Otherwise pr

oceed to

step 5.

5. Control Module is

defective.

Replace Control Module.

Figure 28:

TROUBLESHOOTING