20

18-CD21D1-12

Installer’s Guide

When the thermostat is satisfied, R and W thermostat

contacts open, the gas valve will close, the flames will

extinguish, and the induced draft blower will be de-en-

ergized. The indoor blower motor will continue to run

for the fan off period (fixed at 100 seconds), then will

be de-energized by the control module.

▲

WARNING

!

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could re-

sult in serious injury, death or property damage. Never

test for gas leaks with an open flame. Use a commer-

cially available soap solution made specifically for the

detection of leaks to check all connections. A fire or ex-

plosion may result causing property damage, personal

injury, or loss of life.

START-UP AND ADJUSTMENT

PRELIMINARY INSPECTIONS

With gas and electrical power “OFF”

1. Duct connections are properly sealed

2. Filters are in place

3. Venting is properly assembled

4. Blower door is in place

Turn knob on main gas valve within the unit to the

“

OFF

” position. Turn the external gas valve to “ON”.

Purge the air from the gas lines. After purging, check

all gas connections for leaks with a soapy solution –

DO NOT CHECK WITH AN OPEN FLAME.

Allow

5 minutes for any gas that might have escaped to dis-

sipate. LP Gas, being heavier than air, may require

forced ventilation. Turn the knob on the gas valve in

the unit to the “ON” position.

COMBUSTION AND INPUT CHECK

1. Make sure all gas appliances are off except the fur-

nace.

2. Clock the gas meter with the furnace operating

(determine the dial rating of the meter) for one

revolution.

3. Match the “Sec” column in the gas flow (in cfh) Ta-

ble 13 with the time clocked.

4. Read the “Flow” column opposite the number of

seconds clocked.

5. Use the following factors if necessary:

For 1 Cu. Ft. Dial Gas Flow CFH =

Chart Flow Reading ÷ 2

For 1/2 Cu. Ft. Dial Gas Flow CFH =

Chart Flow Reading ÷ 4

For 5 Cu. Ft. Dial Gas Flow CFH =

10X Chart Flow Reading ÷ 4

6. Multiply the final figure by the heating value of

the gas obtained from the utility company and

compare to the nameplate rating. This must not

exceed the nameplate rating.

Gas Valve Adjustment

Changes can be made by adjusting the manifold pres-

sure (See Table 12), or changing orifices (orifice

change may not always be required). To adjust the

manifold pressure:

1. Turn off all electrical power to the system.

2. Attach a manifold pressure gauge with flexible

tubing to the outlet pressure boss marked “OUT

P” on White-Rodgers gas valve model 36G or 36J.

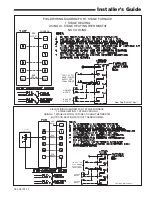

See Figure 26 for White-Rodgers gas valve model

36J. See Figure 25 for White-Rodgers gas valve

model 36G.

3. Loosen (Do Not remove) the pressure tap test set

screw one turn with 3/32" hex wrench.

a. The pressure tap adjustment kit (KIT07611)

contains a 3/32" hex wrence, a 5/16" hose and

a connector and can be ordered through Global

Parts.

4. Turn on system power and energize valve.

5. Adjust gas heat by removing the adjustment regu-

lator cover screw.

a. To increase outlet pressure, turn the regulator

adjust screw clockwise.

b. To decrease outlet pressure, turn the regulator

adjust screw counterclockwise.

c. Adjust regulator until pressure shown on mano-

meter matches the pressure specified in Table

12.

1. The input of no more than nameplate rating

and no less than 93% of the nameplate rating,

unless the unit is derated for high altitude.

d. Replace and tighten the regulator cover screw

securely.

6. Cycle the valve several times to verify regulator

setting.

a. Repeat steps 5-6 if needed.

7. Turn off all electrical power to the system.

8. Remove the manometer and flexible tubing and

tighten the pressure tap screw.

As the induced draft blower comes up to speed, the

pressure switch contacts will close and the ignitor

warm up period will begin. The ignitor will heat for

approx. 20 seconds, then the gas valve is energized to

permit gas flow to the burners. The flame sensor con-

firms that ignition has been achieved within the 6 sec-

ond ignition trial period.

After the flame sensor confirms that ignition has been

achieved, the delay fan ON period (fixed at 45 seconds)

begins timing. After the delay of 45 seconds, the in-

door blower motor will be energized and will continue

to run during the heating cycle.