Installer’s Guide

18-CD21D1-12

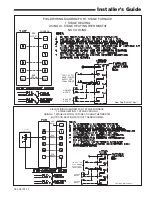

When the upflow furnace is installed in the hori-

zontal right or left application and a return duct

is attached to the top side as shown in Figure 11,

remove the filter from the furnace and install in a

remote location.

Do not install the filter in the return duct directly

above the furnace in horizontal applications.

When the upflow furnace is installed in the hori-

zontal right or left application and a close coupled

(less than 36") return duct is attached to the bot

-

tom side of the furnace as shown in Figure 11, se-

curely attach a 1/2" mesh metal hardware cloth

protective screen to the inside bottom of the filter

grill

to prevent personal injury from contact-

ing moving parts when reaching into the re-

turn opening to replace the filter.

Close coupled (less than 36") return (filter directly

beneath bottom side return) is not recommended

due to noise considerations.

Downflow Furnaces:

Brackets are factory sup

-

plied to mount filters in the return air duct work.

8. Connect the duct work to the furnace. See Outline

Drawing for supply and return duct size and loca-

tion. Flexible duct connectors are recommended

to connect both supply and return air ducts to the

furnace.

If only the front of the furnace is accessible, it is

recommended that both supply and return air ple-

nums are removable.

9.

The horizontal installation of the upflow fur-

nace requires an external filter section. Do

NOT use the bottom return filter within the

furnace. Filter kits are available for horizon-

tal applications.

10. When replacing a furnace, old duct work should

be cleaned out. Thin cloths should be placed over

the registers and the furnace fan should be run for

10 minutes. Don’t forget to remove the cloths be-

fore you start the furnace.

FILTER

REMOVE FILTER FROM UPFLOW

FURNACE WHEN RETURN DUCT IS

ATTACHED TO FURNACE TOP SIDE

(HORIZONTAL LEFT OR RIGHT AP-

PLICATIONS) AS SHOWN.

Close coupled (less than 36")

return (filter directly beneath bottom

side return) not recommended due to

noise considerations. If used, securely

attach 1/2" mesh metal hardware cloth

protective screen to the inside bottom

of filter grill.

q

*

SEE OUTLINE DRAWING

w

LOCATING

NOTCHES

PROVIDED

FOR SIDE

RETURN

CUTOUT

FRONT

of Furnace

*

*

*

*

CUT OUT

FOR

SIDE

FILTER

BOTTOM FILTER RACK INSTALLATION

Airflow

e

11. The bottom panel of the upflow furnace must be

removed for bottom return air. After removing the

filter, lay the furnace on its back. Remove the two

5/16" hex screws securing the front of the bottom

channel to the cabinet. Rotate the channel down-

ward (or remove by lowering the front edge of the

channel and pulling forward). Slide the bottom

return air panel out of the cabinet. Rotate the

front channel to its original position and reinstall

the two 5/16” screws.

RETURN AIR FILTERS

TYPICAL UPFLOW RETURN AIR

FILTER INSTALLATIONS

These furnaces require high velocity type air filters.

The filters may be installed within the furnace blower

compartment for UPFLOW furnaces in either a BOT

-

TOM or SIDE (left side or right side) return air inlet.

Some filters may need to be trimmed for side or bottom

filter use.

NOTE:

For upflow 5 ton airflow models where the airflow

requirement exceeds 1800 CFM - Models will require

return air openings and filters on: (1) both sides, or (2)

one side and the bottom, or (3) just the bottom.

The furnace and the bottom filter rack, BAYRACK960,

installation can be seen in Figure 13.