18-AD35D1-2D-EN

3

Installer’s Guide

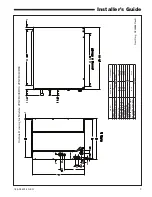

F. FURNACE IN HORIZONTAL RIGHT POSITION

▲

CAUTION

!

Both the coil and furnace must be fully supported. Do not

attempt to suspend the coil using the brackets.

Note: when installing onto an S-Series furnaces in horizontal

right or downflow configuration the flanges will be bent

downward.

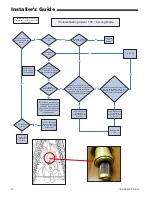

1. HORIZONTAL RIGHT COIL CONVERSION: While not

required, optional removal of some coil components will

maximize airflow efficiency.

a. Remove the coil by sliding the coil out of the coil

enclosure.

b. Optional but recommended: Remove the factory in-

stalled two-piece baffle assembly from the top of the coil

by removing the 5/16” hex head screws. See Figure 2.

Replace only the top baffle using the same screws previ-

ously provided.

c. Optional but recommended: On 4TXCC009DS and

4TXCD010DS only, remove the (2) outer water diverter

baffles by removing the 5/16” hex head screws. See Fig-

ure 6.

IMPORTANT:

The 4TXC cased coil must be placed downstream of the

furnace. See Figure 6 for proper orientation.

2. When the noncondensing Upflow/Horizontal furnace is

placed on its right side for right airflow, the furnace top

flange meets the cased coil top flange. The coil flange fits

inside of the furnace flange. See Figure 7.

3. There are self drilling screws included which can be used

for this connection. Seal all gaps between the furnace and

coil.

UPFLOW MODEL IN

HORIZONTAL RIGHT AIRFLOW POSITION

Airflo

w

Co

mf

or

t

TM

co

il

CASED COIL

Figure 6

CASED

COIL

UPFLOW

FURNACE

TOP COIL FLANGE

FITS INSIDE OF

FURNACE

TOP FLANGE FOR

HORIZONTAL RIGHT

APPLICATION

UPFLOW

Figure 5

Figure 7

Note: when installing coil onto an S-Series furnaces

in horizontal right or downflow configuration, bend

the flanges downward for a flush fit.

Содержание 4TXCA002DS3HCA

Страница 11: ...18 AD35D1 2D EN 11 Installer s Guide...