18-AD35D1-2D-EN

5

Installer’s Guide

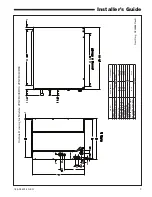

Maximum airflow setting, CFM

Coil

Upflow

Horizontal Left

4TXCA002DS3HCA

900

800

4TXCA032DS3HCA

1350

1125

4TXCB003DS3HCA

1125

1000

4TXCB004DS3HCA

1350

1200

4TXCC005DS3HCA

1350

1200

4TXCB006DS3HCA

1800

1600

4TXCC007DS3HCA

1800

1600

4TXCD008DS3HCA

1800

1600

4TXCC009DS3HCA

2250

2000

4TXCD010DS3HCA

2250

2000

Coil

Downflow

Horizontal Right

4TXCA002DS3HCA

750

900

4TXCA032DS3HCA

1200

1350

4TXCB003DS3HCA

925

1125

4TXCB004DS3HCA

1100

1350

4TXCC005DS3HCA

1100

1350

4TXCB006DS3HCA

1475

1800

4TXCC007DS3HCA

1475

1800

4TXCD008DS3HCA

1475

1800

4TXCC009DS3HCA

1850

2250

4TXCD010DS3HCA

1850

2250

H. MAXIMUM AIRFLOW SETTING, CFM

NOTE:

Water blow-off could occur in certain installation posi-

tions if the airflow setting exceeds the maximum values

listed.

IMPORTANT:

Do not unseal refrigerant tubing until ready to fit refriger-

ant lines.

There is only a holding charge of dry air in the indoor coil,

therefore no loss of operating refrigerant charge occurs when

the sealing plugs are removed.

NOTE:

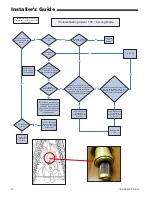

TXV bulb MUST be protected (wrapped with wet rag) or

removed, while brazing the tubing. Overheating of the

sensing bulb will affect the functional characteristics and

performance of the comfort coil.

1. Remove both rubber plugs from the indoor coil.

2. Field supplied tubing should be cut square, round and free

of burrs at the connecting end. Clean the tubing to prevent

contaminants from entering the system.

3. Run the refrigerant tubing into the stub tube sockets of

the indoor unit coil.

PAINTED AREAS OF THE UNIT MUST BE SHIELDED

DURING BRAZING.

4. Flow a small amount of nitrogen through the tubing while

brazing.

5. Use good brazing technique to make leakproof joints.

6. Minimize the use of sharp 90 degree bends.

7. Insulate the suction line and its fittings.

8. Do NOT allow un-insulated lines to come into contact with

each other.

I. INSTALLING / BRAZING REFRIGERANT LINES

▲

CAUTION

!

Do NOT open refrigerant valve at the outdoor unit until the

refrigerant lines and coil have been brazed, evacuated, and

leak checked. This would cause contamination of the refriger-

ant or possible discharge of refrigerant to the atmosphere.

1. The following steps are to be considered when installing

the refrigerant lines:

a. Determine the most practical way to run the lines.

b. Consider types of bends to be made and space limita-

tions.

c. Route the tubing making all required bends and properly

secure the tubing before making final connections.

NOTE:

Refrigerant lines must be isolated from the structure

and the holes must be sealed weather tight after installation.

NOTE:

The TXV setting on this unit may run high superheat

(15-25°F) by design when measured at the outdoor unit.

Содержание 4TXCA002DS3HCA

Страница 11: ...18 AD35D1 2D EN 11 Installer s Guide...