28

STOP

STOP

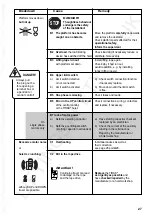

Breakdown

Cause

Remedy

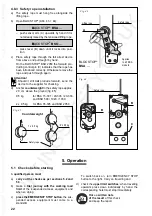

Platform moves up

DANGER

!

but not down

Thoughtless behaviour

endangers the safety

of the installation!

D1 The platform has hit

Move platform carefully upwards,

an obstacle

and remove the obstacle.

or has become caught

Check platform parts affected for their

on an obstacle.

operational safety.

Inform the supervisor.

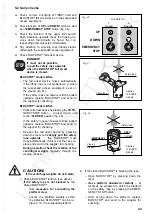

D2 BLOCSTOP

®

fall arrest device

holds the platform

on the safety rope.

a)

Lifting rope rupture

a) + b)

Evacuate platform and follow

the instructions in section

b)

Failure of the hoist

5.6, page 25.

c)

Platform becoming caught

c) Move upwards until the loaded

(with BLOCSTOP

®

BSA…)

lifting rope opens the BLOCSTOP

®

.

d)

Inclined position of the platform

d) Move lower platform end

(with BLOCSTOP

®

BSA…)

upwards until the loaded lifting

rope opens the BLOCSTOP

®

.

e)

Hoist speed too high

e) Check hoist.

(with BLOCSTOP

®

BSO…)

f)

Trigging speed too low

f)

Replace BLOCSTOP

®

and send

(with BLOCSTOP

®

BSA…)

for checking.

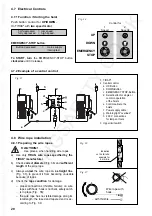

DANGER!

Defective BLOCSTOP

®

fall arrest devices

endanger the operational safety of the installation!

They must be replaced as a matter of urgency!

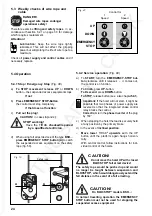

D3 Error in DOWN control circuit

If necessary Emergency descent

of the central control system

(details in section 5.5)

or the TIRAK

®

hoist.

Check connections, wiring, contactors

etc. and replace if necessary.

Should these steps not explain the cause and provide a remedy please contact

GREIFZUG Hebezeugbau GmbH, other TRACTEL Group company, or a hoist workshop.

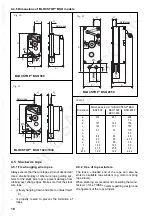

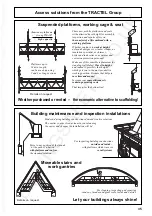

a)

Amchoring the platform:

– Lower working platform to the ground with

slightly tensioned ropes

or

– anchor working platform to the building in

order to secure it against swinging motion.

b)

Disconnect the power supply to prevent any

unauthorised operation:

– Disconnect power supply cable from site dis-

tributor

or, if available

– turn and lock the main switch to “0“.

7. Out of operation

DANGER!

Always pull

the plug out be-

fore opening a

terminal box or

a pendant or

central control!