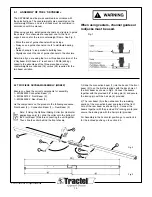

© 2012 Tractel Ltd. All Rights Reserved.

17

4.4

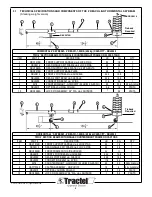

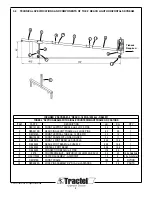

CONTINUED - ASSEMBLY OF ROOF BEAM

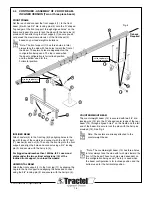

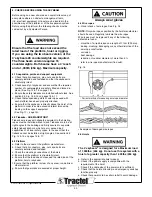

Level the outrigger beam and support assembly. Attach the

thimble end of the suspension wire rope to beam using a 5/8",

3-1/4 ton shackle (1). See Fig 10. Once the rope is attached,

set the assembly into working position. For beams with casters,

apply the brakes on all of the casters. Once in position install

taut tieback to the rear shackle (Fig. 13) as shown on Page 16

& 17 Fig. 14 & 15.

Note: The optional sliding collar shown in Fig. 10 is

for suspension only in the horizontal position. It is

not recommended for the inclined suspension beam.

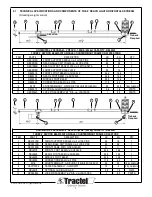

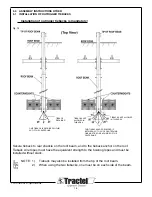

If you are using the two beam version of the 4’

skybeam 28 counterweights are required. The three

beam version requires 16 counterweights. Both

beams have a 4’ reach and a 1,000lb. (454 kg)

maximum capacity.

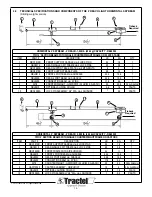

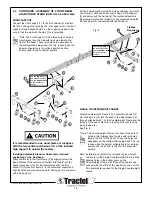

Add the counterweights (#3348) (up to 32 max.) to the

counterweight beam (See fig 8). Check once again the

maximum admissible load (see Section 4.4 page 17 –

Calculation of counterweight) related to the reach and the

number of counterweights on the counterweight beam. Install all

required counterweights on the counterweight beam by lowering

them over the extension pole, starting with the two inside poles.

Distribute the weight as equally as possible on each side of the

frame. See Fig.12.

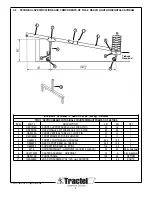

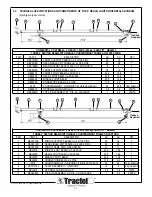

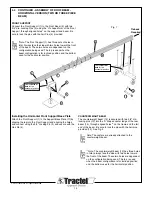

When all weights are in place install the locking pin to prevent

removal. See Fig. 13.

Attach the tieback wire rope at the back of the rear beam,

to the rear shackle inside. Always insure the tieback has

equivalent strength to the hoisting rope and they must be

installed without slack. See Fig 13. See Section 4.4 Fig. 11

& 12 for proper tie back instructions.

1

Primary wire rope is attached

here (see details below)

Beam Shackle

5/8” Shackle

Tieback Line

Wire Rope Thimble

Primary Wire Rope

Optional

sliding collar

Locking Pin

Rear shackle and

safety tieback as

required

Insert weights over the post,

starting on the inside and

evenly distributing from side

to side.

Fig. 10

Fig. 11

Fig. 12

Fig. 13