– 10 –

■

System Requirements

•

Minimum refrigerant line length between the outdoor

unit and indoor unit is 16

’

5” (5 m)

•

Maximum pipe lengths

Allowable

pipe length

(ft (m))

Height difference

(Indoor-outdoor H)

(ft (m))

Number

of bent

portions

Total length

L

Indoor unit:

Upper

Outdoor unit:

Lower

10 or less

164’1” (50)

98’5” (30)

98’5” (30)

Figure of Single

H

L

Indoor Unit

Outdoor Unit

Refrigerant sizes

Liquid side

Gas side

Outer

diameter

Thickness

Outer

diameter

Thickness

Ø3/8”

(9.5 mm)

0.03”

(0.8 mm)

Ø5/8”

(15.9 mm)

0.04”

(1.0 mm)

Flare nuts and

fl

aring

•

The

fl

are nuts and

fl

aring are different from those for

the conventional refrigerant.

Use the flare nuts supplied with the air conditioner or

those for R410A.

•

Before performing

fl

aring, carefully read

“REFRIGERANT PIPING”

Insulation (Local supplied)

Both lines need to be insulated. Use a minimum 0.4”

(10 mm) wall thickness.

Refrigerant charge

Length of refrigerant

pipe connected to

indoor/outdoor unit

Additional refrigerant

16’5” - 98’5”

(5 - 30 m)

None

*98’5” - 246’1”

(30 - 75 m)

Add 0.43 oz/ft (40 g/m) of

refrigerant for piping that exceeds

98’5” (30 m) up to 246’1” (75 m).

*

Caution during addition of refrigerant

Max. amount of additional refrigerant is 1.8 lbs

(800 g).

Charge the refrigerant accurately. Overcharging

may cause serious trouble with the compressor.

*

Minimum refrigerant pipe is 16’5” (5 m).

This may cause a malfunction of the compressor or

other devices.

Metering Device is an electronic EXV (PMV) in

outdoor unit.

■

Connecting power and control

cables (Field supplied)

•

The main power is supplied to the outdoor unit.

The

fi

eld supplied connecting cables from the

outdoor unit to the indoor unit consist for 4 wires

and provides the power for the indoor unit as well as

the communication signal between the outdoor and

indoor unit.

•

System interconnection wire size must be AWG16.

•

Breaker must have a capacity speci

fi

ed in the

following table.

•

All wiring must comply with local electric codes and

NEC (National Electric Code) or CEC (Canadian

Electric Code).

Model RAV-

SP242

Power supply

208/230 V, 60 Hz

MCA

17 A

MOCP (MAX Fuse/CB)

25 A

Breaker

20 A

System interconnection wires

AWG16

Field power supply wire

AWG12

MCA = Minimum Circuit Amps

MOCP = Maximum Over Protection Device Amps.

6

Vacuum

■

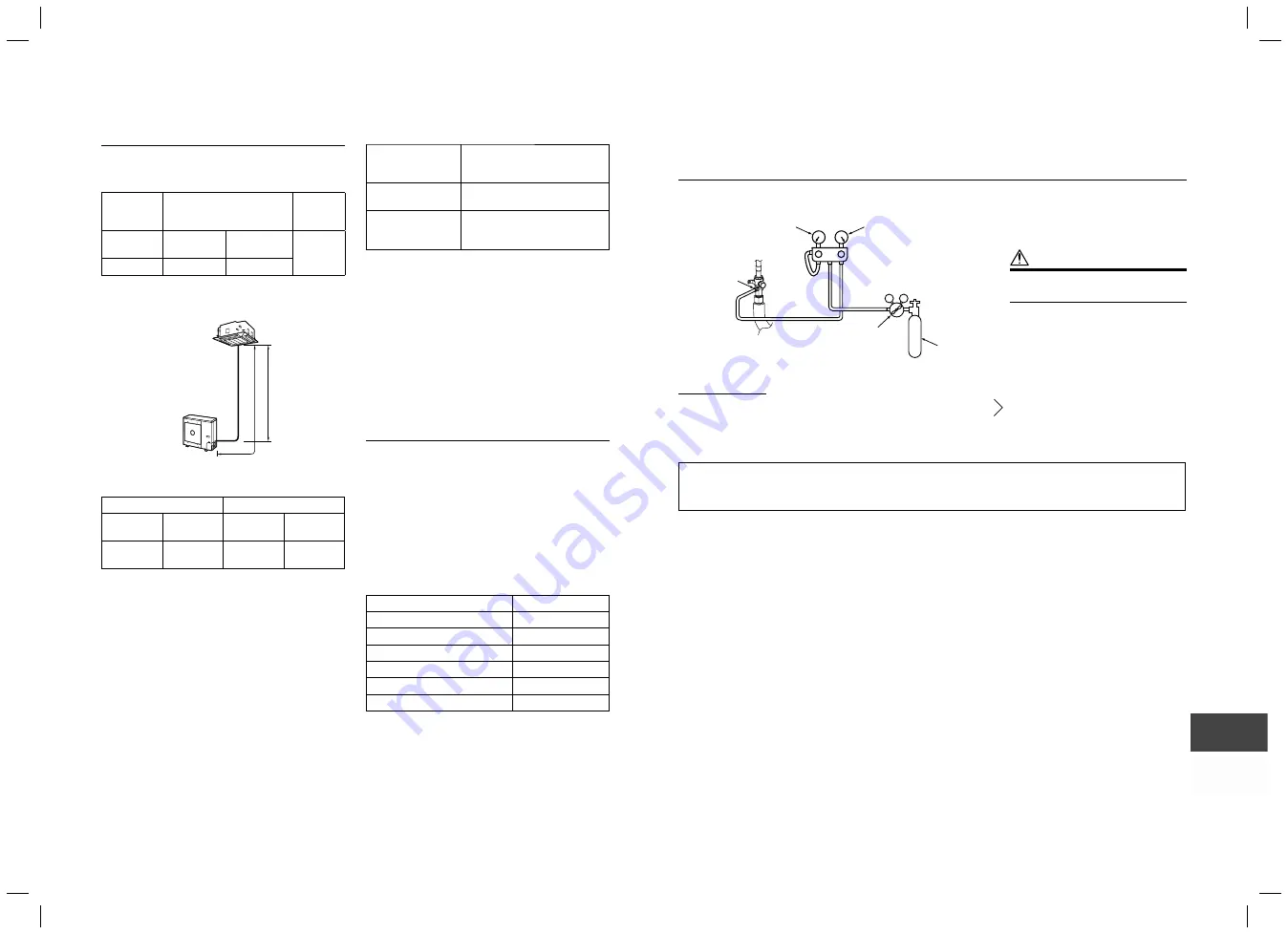

Vacuum test

After completing the refrigerant piping work, perform a vacuum test. Connect a nitrogen gas cylinder and

pressurize the pipes with nitrogen gas as follows to conduct the vacuum test.

CAUTION

Never use oxygen, flammable gas,

or noxious gas for the airtight test.

V

L

V

H

Low pressure gauge

Charge port

High pressure gauge

Pressure reducing

valve

Nitrogen gas

Gauge manifold

Gas leak check

Step 1....Pressurize to

0.5 MPa

(5 kg/cm²G) for 5 minutes or longer.

Major leaks can be discovered.

Step 2....Pressurize to

1.5 MPa

(15 kg/cm²G) for 5 minutes or longer.

Step 3....Pressurize to

4.15 MPa

(42 kg/cm²G) for 24 hours. ................ Micro leaks can be discovered.

(However, note that when the ambient temperature differs during pressurization and after 24 hours, the pressure

will change by approximately 0.01 MPa (0.1 kg/cm²G) per 1°C, so this should be compensated.)

If the pressure drops in steps 1 through 3, check the connections for leakage.

Check for leaks with foaming liquid, etc., take steps to fix the leaks such as brazing the pipes again and

tightening the flare nuts, and then perform the airtight test again.

*

After the vacuum test is completed, evacuate the nitrogen gas.

EN

TH

ID

19-EN

20-EN

1131601101 EN FR ES.indb 10

1131601101 EN FR ES.indb 10

4/8/2565 BE 10:14

4/8/2565 BE 10:14