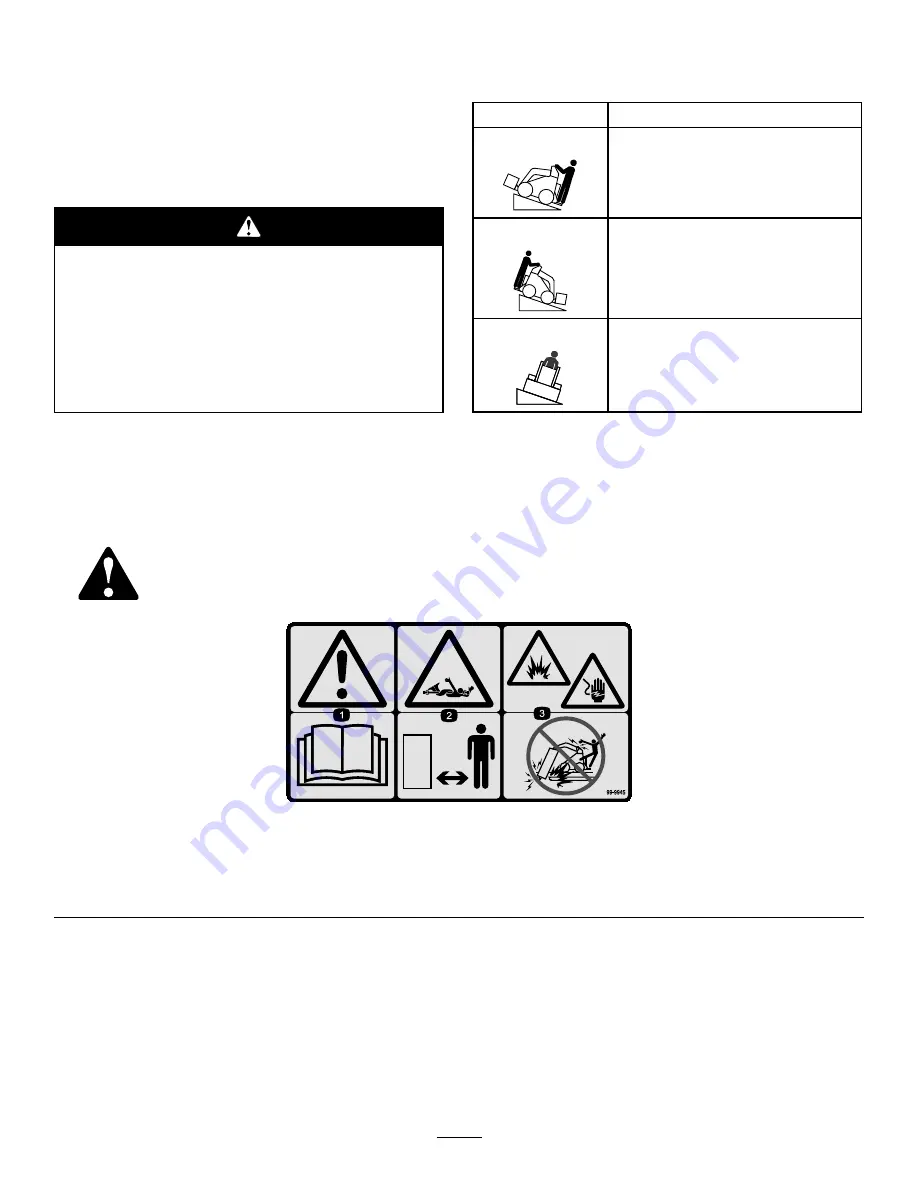

Stability Ratings

To determine the degree of slope you can traverse with

the attachment installed on a traction unit, find the

stability rating for the hill position you want to travel

in the appropriate table below, then find the degree of

slope for the same rating and hill position in the Stability

Data section of the traction unit

Operator’s Manual

.

Exceeding the maximum recommended slope

can cause the traction unit to tip, crushing you

or bystanders.

Do not drive the traction unit on a slope steeper

than the maximum recommended slope, as

determined in the following tables and the

traction unit

Operator’s Manual

.

Important:

If you have a traction unit other than

the TX, the bore drive head is rated for use without

the counterweight. If you use the counterweight

with the boring unit, the traction unit will be less

stable in the front and side uphill positions.

Orientation

Stability Rating

Front Uphill

D

Rear Uphill

B

Side Uphill

C

Safety and Instructional Decals

Safety decals and instructions are easily visible to the operator and are located near any area of

potential danger. Replace any decal that is damaged or lost.

99-9945

1.

Warning—read the

Operator’s Manual

.

2.

Entanglement hazard, shaft—keep bystander’s a safe distance from the machine.

3.

Explosion and electric shock hazard—do not dig in areas with buried gas or electrical lines; contact local power organizations

before digging.

4

Содержание Sitework Systems 22420

Страница 10: ...Notes 10...

Страница 11: ...Notes 11...