Fuel Specification

Important:

Use only ultra-low sulphur diesel fuel.

Fuel with higher rates of sulfur degrades the diesel

oxidation catalyst (DOC), which causes operational

problems and shortens the service life of engine

components.

Failure to observe the following cautions may damage

the engine.

•

Never use kerosene or gasoline instead of diesel fuel.

•

Never mix kerosene or used engine oil with the diesel

fuel.

•

Never keep fuel in containers with zinc plating on the

inside.

•

Do not use fuel additives.

Petroleum Diesel

Cetane rating:

45 or higher

Sulfur content:

Ultra-low sulfur (<15 ppm)

Fuel Table

Diesel fuel specification

Location

ASTM D975

No. 1-D S15

No. 2-D S15

USA

EN 590

European Union

ISO 8217 DMX

International

JIS K2204 Grade No. 2

Japan

KSM-2610

Korea

•

Use only clean, fresh diesel fuel or biodiesel fuels.

•

Purchase fuel in quantities that can be used within 180

days to ensure fuel freshness.

Use summer-grade diesel fuel (No. 2-D) at temperatures

above -7°C (20°F) and winter-grade fuel (No. 1-D or No.

1-D/2-D blend) below that temperature.

Note:

Use of winter-grade fuel at lower temperatures

provides lower flash point and cold flow characteristics

which eases starting and reduces fuel filter plugging.

Using summer-grade fuel above -7°C (20°F) contributes

toward longer fuel pump life and increased power compared

to winter-grade fuel.

Biodiesel

This machine can also use a biodiesel blended fuel of up to

B20 (20% biodiesel, 80% petroleum diesel).

Sulfur content:

Ultra-low sulfur (<15 ppm)

Biodiesel fuel specification:

ASTM D6751 or EN14214

Blended fuel specification:

ASTM D975, EN590, or JIS

K2204

Important:

The petroleum diesel portion must be

ultra-low sulfur.

Observe the following precautions:

•

Biodiesel blends may damage painted surfaces.

•

Use B5 (biodiesel content of 5%) or lesser blends in

cold weather.

•

Monitor seals, hoses, gaskets in contact with fuel as

they may be degraded over time.

•

Fuel filter plugging may be expected for a time after

converting to biodiesel blends.

•

Contact your authorized Toro distributor for more

information on biodiesel.

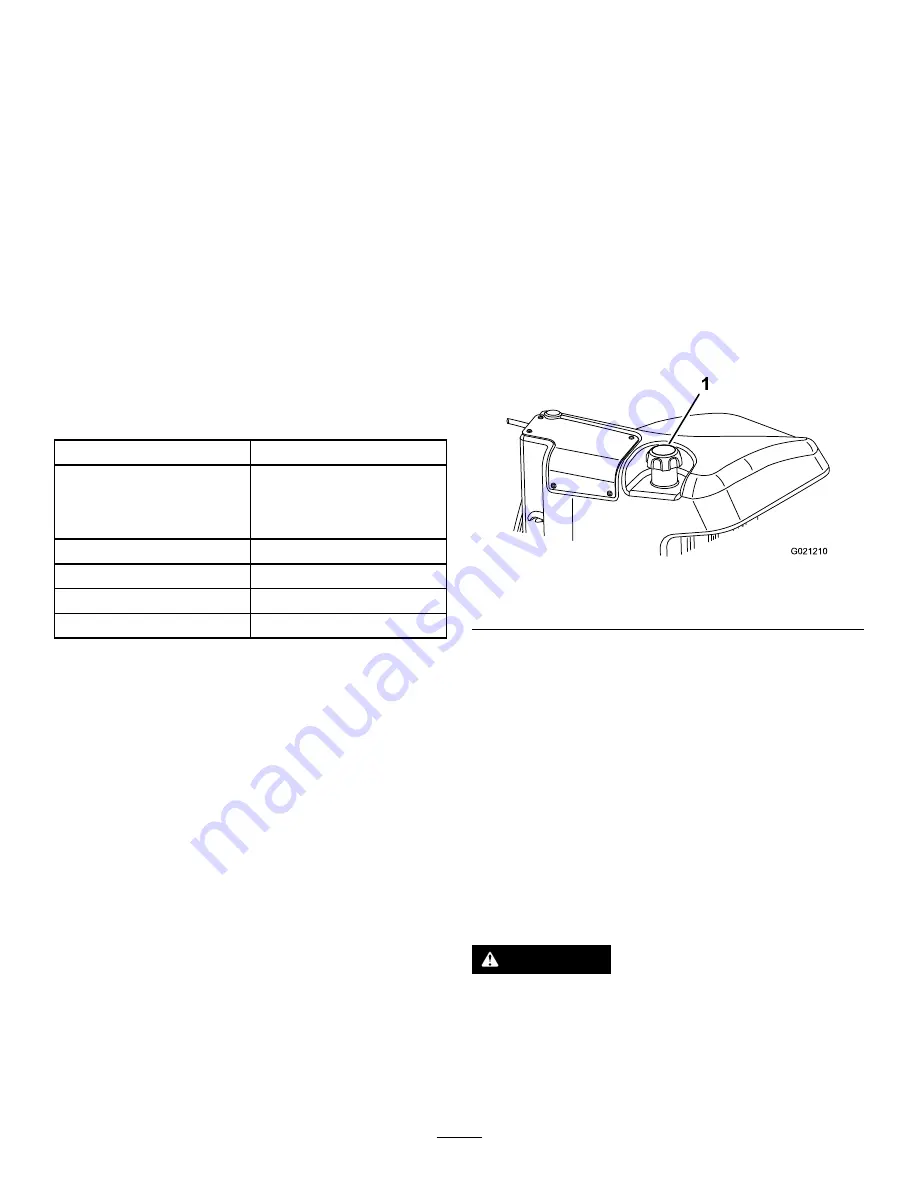

Adding Fuel

1.

Park the machine on a level surface, lower the cutting

units, engage the parking brake, shut off the engine,

and remove the key.

2.

Using a clean rag, clean area around fuel-tank cap.

3.

Remove the cap from the fuel tank (

).

g021210

Figure 49

1.

Fuel-tank cap

4.

Fill the tank until the level is 6 to 13 mm (1/4 to 1/2

inch) below the bottom of the filler neck.

5.

Install the fuel-tank cap tightly after filling the tank.

Note:

If possible, fill the fuel tank after each use.

This minimizes possible buildup of condensation

inside the fuel tank.

Performing Daily Maintenance

Service Interval:

Before each use or daily

Before starting the machine each day, perform the Each

Use/Daily procedures listed in

Maintenance (page 49)

.

Checking the Interlock Switches

Service Interval:

Before each use or daily

CAUTION

If safety interlock switches are disconnected or

damaged, the machine could operate unexpectedly,

causing personal injury.

•

Do not tamper with the interlock switches.

•

Check the operation of the interlock switches

daily and replace any damaged switches before

operating the machine.

30